Exciter for detonating tube

A technology of exciter and detonator, which is applied to blasting cylinders, weapon accessories, offensive equipment, etc., can solve the problems of increased cost, difficulty in reuse, oxidation, etc., and achieve the effect of reducing blasting cost and easy to achieve.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

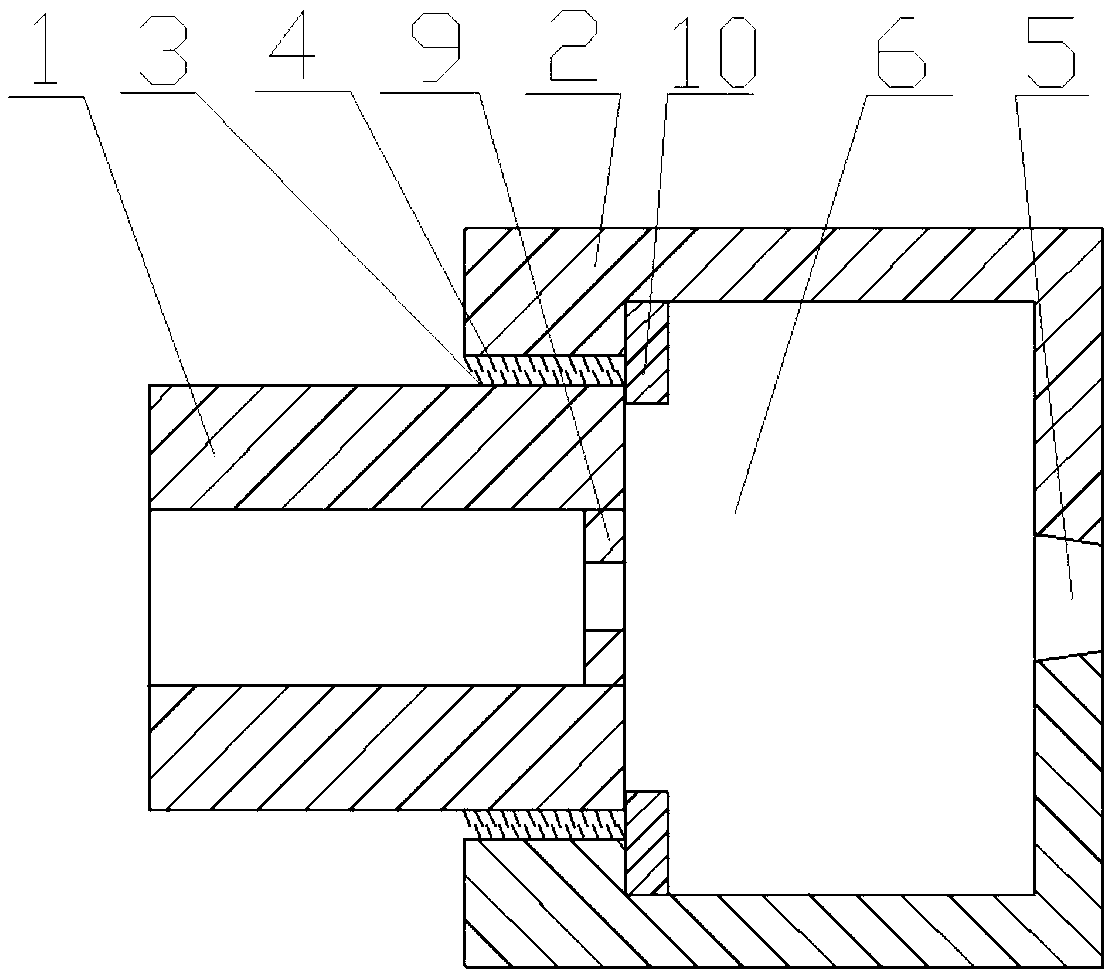

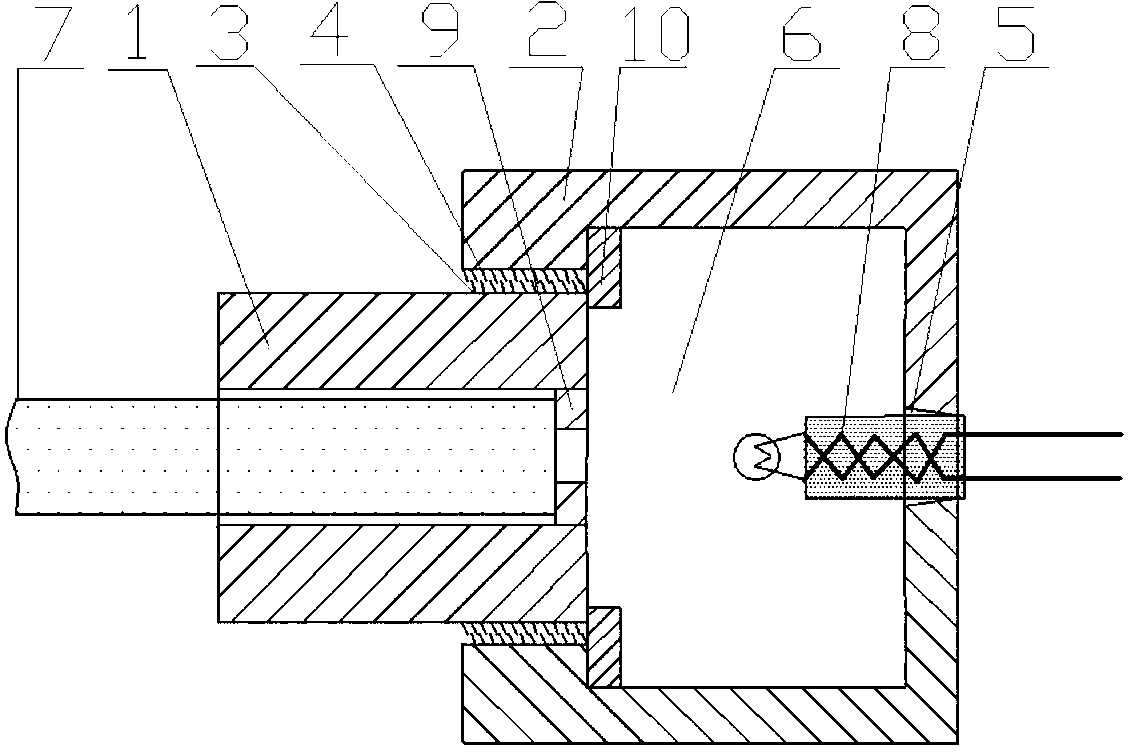

[0013] Nonel igniters, such as figure 1 , figure 2 As shown, it includes a fixing part 2 and an inserting part 1. One end of the fixing part 2 is provided with an internal thread 4, and the other end of the fixing part 2 is provided with a fixing hole 5, and the fixing hole 5 and the internal thread 4 are communicated through a cavity 6; The insertion part 1 is a cylinder with a through hole at the center of the shaft. An external thread 3 corresponding to the internal thread 4 is provided on the outside of the insertion part 1 . The through hole of the insertion part 1 communicates with the cavity 6 .

[0014] The fixing hole 5 is a tapered hole, the outer diameter of which is smaller than the inner diameter. The diameter of the outer hole is slightly smaller than the diameter of the ignition element 8, and the ignition element 8 can be fixed on the fixing hole 5 through its injection molding part.

[0015] An annular protruding portion 9 is disposed in the through hole at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com