Non-electric coupling multi-section differential detonating circuit

A micro-differential detonation and network technology, applied in the direction of blasting tubes, weapon accessories, offensive equipment, etc., can solve the problems of expensive detonating cord, blasting operation accidents, high blasting costs, etc., to achieve low prices, reduce blasting costs, and spread explosions reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

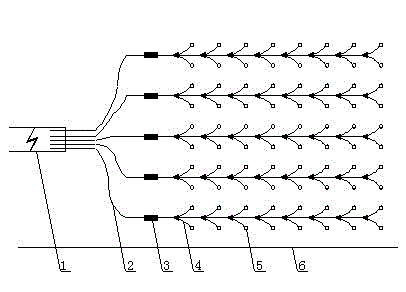

[0013] A non-electrically coupled multi-stage micro-differential initiation network. The detonation network such as figure 1 As shown, it is composed of dry detonating cord 2, hole branch detonating tube 4, blast hole 5 and main millisecond delay detonator 3. A trunk detonating cord 2 is arranged in the middle of every two rows of blastholes 5 on the working face, and each row of blastholes 5 is equipped with a hole branch detonating tube 4, a nonel detonator and a charge bag, and the detonating cord 2 is provided with a dry path. The two blastholes 5 with the cables 2 as symmetrical axes are connected in parallel with the trunk detonating cord 2 clusters through the hole-entry branch detonating tubes 4 in the respective holes. Each trunk detonating cord 2 is connected in parallel with a cluster of excitation devices 1, and each trunk detonating cord 2 is provided with a trunk millisecond delay detonator 3 respectively.

[0014] The delay time of the main millisecond delay d...

Embodiment 2

[0017] A non-electrically coupled multi-stage micro-differential initiation network. The detonation network such as figure 1 As shown, it is composed of dry detonating cord 2, hole branch detonating tube 4, blast hole 5 and main millisecond delay detonator 3. A trunk detonating cord 2 is arranged in the middle of every two rows of blastholes 5 on the working face, and each row of blastholes 5 is equipped with a hole branch detonating tube 4, a nonel detonator and a charge bag, and the detonating cord 2 is provided with a dry path. The two blastholes 5 with the cables 2 as symmetrical axes are connected in parallel with the trunk detonating cord 2 clusters through the hole-entry branch detonating tubes 4 in the respective holes. Each trunk detonating cord 2 is connected in parallel with a cluster of excitation devices 1, and each trunk detonating cord 2 is provided with a trunk millisecond delay detonator 3 respectively.

[0018] The delay time of the main millisecond delay d...

Embodiment 3

[0021] A non-electrically coupled multi-stage micro-differential initiation network. The detonation network such as figure 1 As shown, it is composed of dry detonating cord 2, hole branch detonating tube 4, blast hole 5 and main millisecond delay detonator 3. A trunk detonating cord 2 is arranged in the middle of every two rows of blastholes 5 on the working face, and each row of blastholes 5 is equipped with a hole branch detonating tube 4, a nonel detonator and a charge bag, and the detonating cord 2 is provided with a dry path. The two blastholes 5 with the cables 2 as symmetrical axes are connected in parallel with the trunk detonating cord 2 clusters through the hole-entry branch detonating tubes 4 in the respective holes. Each trunk detonating cord 2 is connected in parallel with a cluster of excitation devices 1, and each trunk detonating cord 2 is provided with a trunk millisecond delay detonator 3 respectively.

[0022] The delay time of the main road millisecond de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com