Blast hole spaced charging device for engineering blasting

A technology of interval charging and blast holes, which is applied in the field of blasting, can solve the problems of small application range, etc., and achieve the effects of improving safety, reducing blasting costs, and good sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with the embodiments.

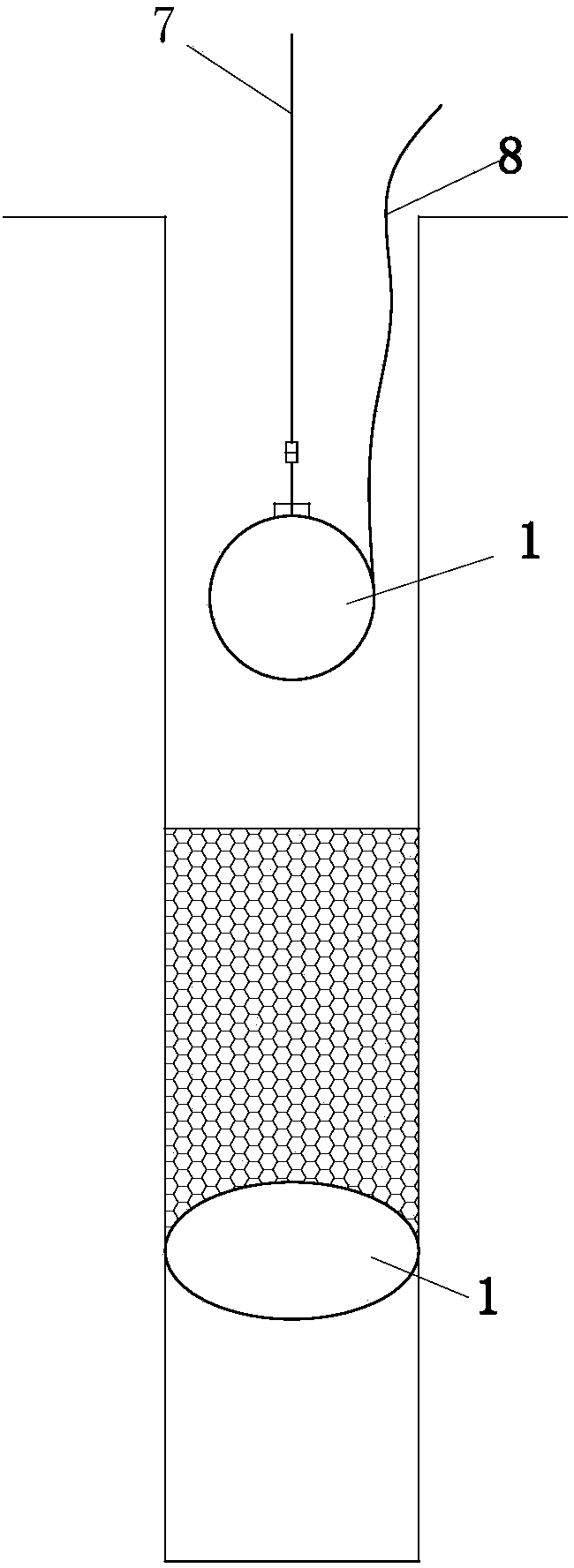

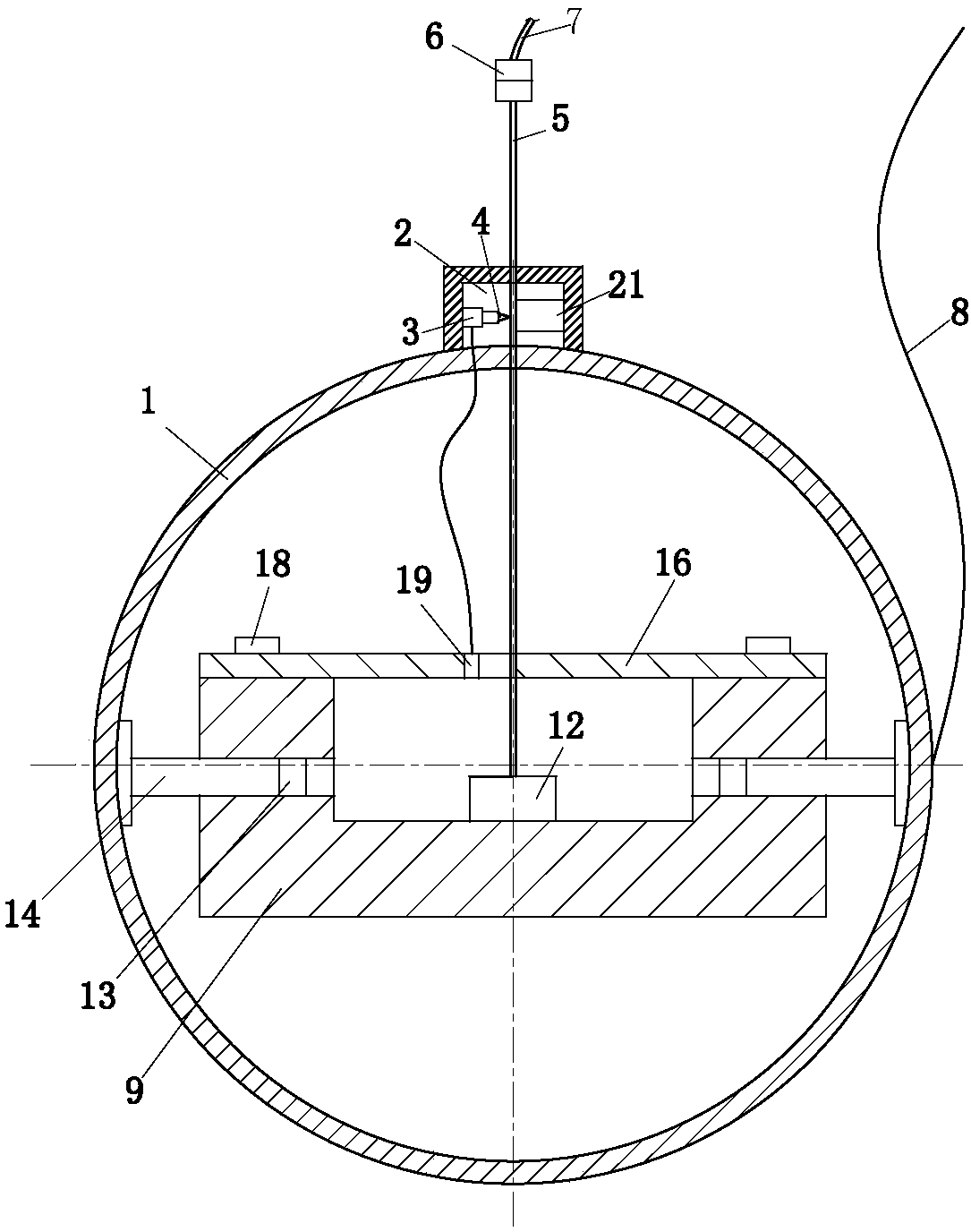

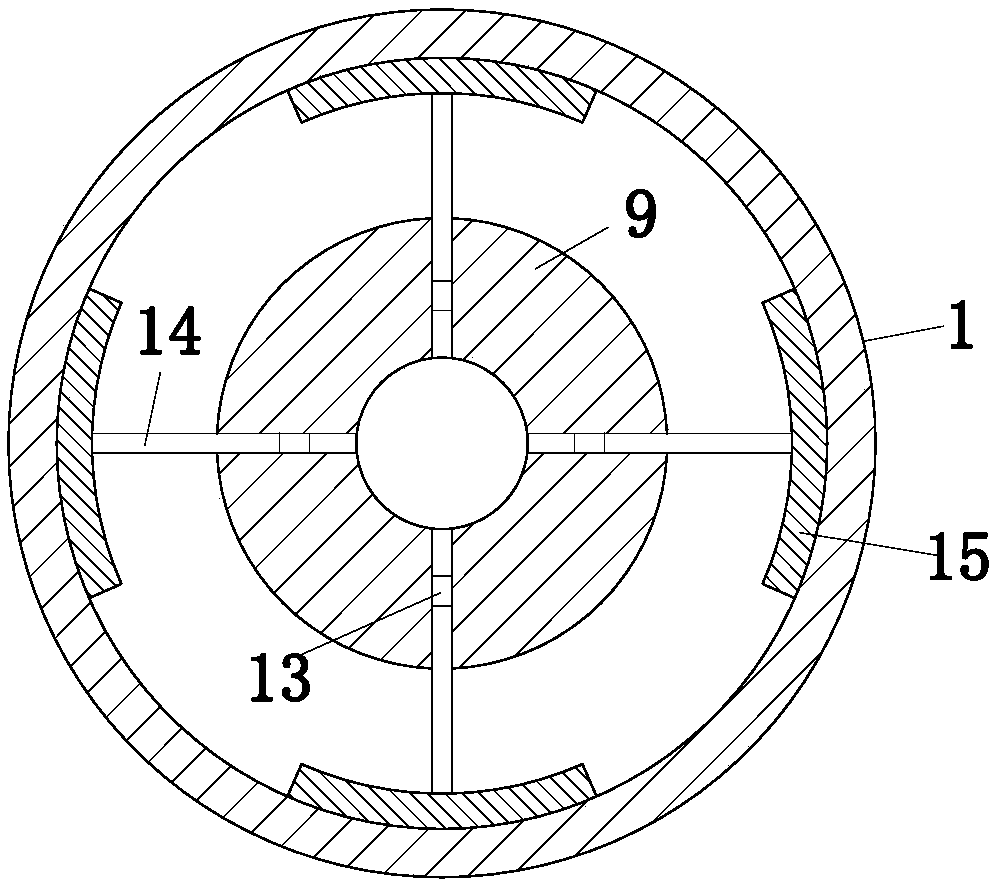

[0023] Such as Figure 1 to Figure 3 Said, a kind of project blasting according to the present invention is used blast hole spacer charging device, comprises housing 1, sealing chamber 2, cylinder 3, cutter 4, trigger wire 5, explosion-proof electrical connection box 6, placement wire 7, Recovery rope 8, disk 9, piston hole 10, groove 11, gas release device 12, piston 13, piston rod 14, support plate 15, sealing end cover 16, explosion-proof sealing gasket 17, screw 18 and air guide hole 19; The shell 1 is a sphere, and the shell 1 is made of a flexible material. In order to improve the safety performance of the present invention, the shell 1 is made of a high temperature and high pressure resistant fireproof rubber material, which can realize explosi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com