Loose blasting excavation construction method of intermediary weathered sandstone stratum rock

A technology of loose blasting and construction methods, applied in blasting and other directions, can solve the problems of prolonging the construction period, excessive blasting force, poor blasting quality, etc., and achieve the effect of high blasting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

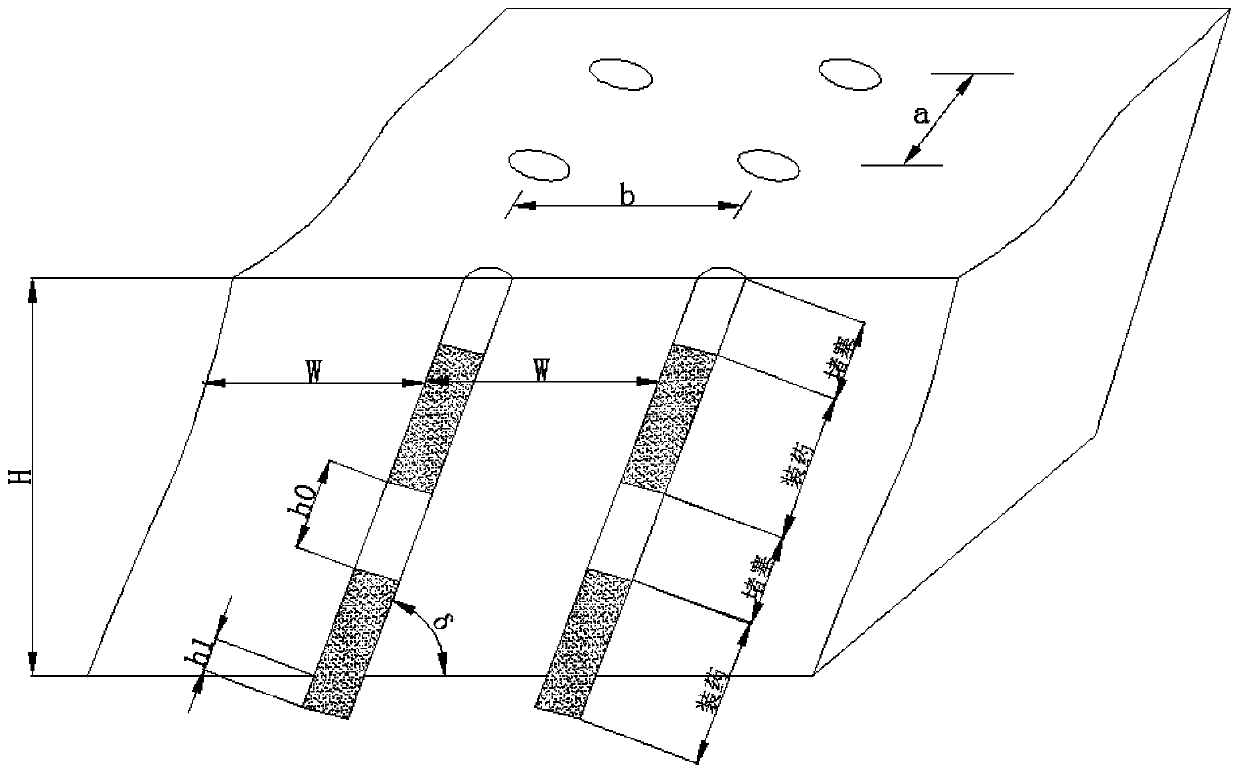

[0042] like figure 1 As shown, the present embodiment provides a construction method for loosening and blasting excavation of medium-weathered sandstone layers, including the following steps: (1) leveling the drilling rig work site; (2) laying holes and charging explosives; (3) network connection; (4) blasting safety alert; (5) blasting, in step (2), when digging depth less than 5m in the lot, the technical parameters of blast hole arrangement are as follows:

[0043] ① Blast hole inclination angle δ: δ=75°;

[0044] ②Bunker hole diameter d: d=40mm;

[0045] ③Step height H: H≥(0.060-0.064)d, that is, H≥2.4-2.56mm, where H=4m;

[0046] ④ Blast hole depth h: h is approximately equal to the excavation depth or step height H, and h≥0.8m, where h=4m;

[0047] ⑤ Minimum resistance line W: W=(0.6-0.8)H, where W=0.8H=3.2m;

[0048] ⑥ Overdrilling depth h1 at the bottom of the blast hole: h1 = 0.25W = 0.8m;

[0049] ⑦Clogging length h0: h0=0.9W=2.88m;

[0050] ⑧ Blast hole spacin...

Embodiment 2

[0068] This embodiment is further optimized on the basis of embodiment 1. Specifically, in step (2), the clay with a certain humidity is selected for backfilling the clogged material after charging, and is backfilled in multiple times, and wood is used for backfilling. The purpose of tamping with a stick is to prevent holes from being stuck.

Embodiment 3

[0070] This embodiment is further optimized on the basis of Embodiment 1. Specifically, in step (3), the network connection adopts double detonators and double nonel networks. Then connect the detonator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com