Sand blasting device for motor train unit air compressor crankcase casting mold machining

A technology for air compressors and casting molds, which is used in used abrasive processing devices, manufacturing tools, metal processing equipment, etc., and can solve problems such as low sandblasting quality, incomplete sandblasting, and increased rework.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

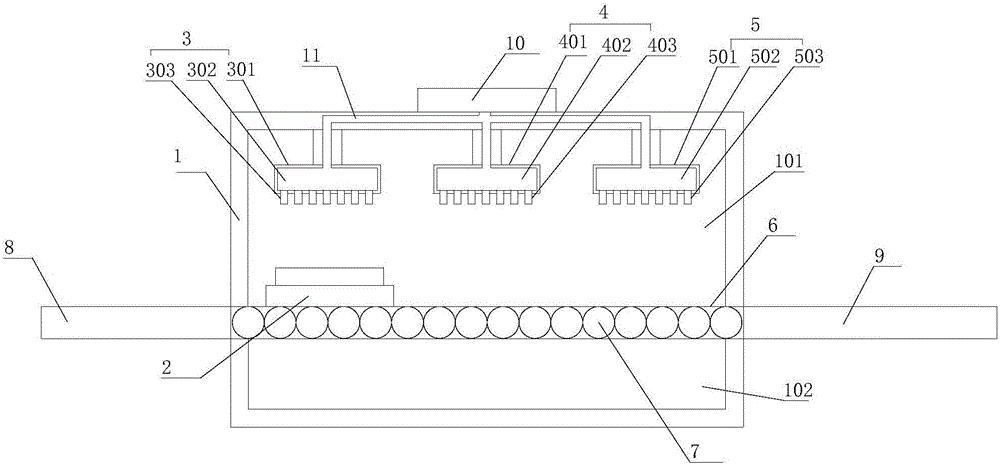

[0020] refer to figure 1 , the present invention proposes a sandblasting device for casting molds for air compressor crankcases of EMUs, comprising a sandblasting box 1, a loading plate 2, a first sandblasting assembly 3, a second sandblasting assembly 4, and a third sandblasting assembly Component 5, sand storage box 10, first sensor, second sensor, third sensor, controller, wherein:

[0021] The sandblasting box 1 is provided with a partition plate 6 arranged horizontally. The partition plate 6 divides the inside of the sandblasting box 1 into a sandblasting chamber 101 and a recovery chamber 102. Between the feed end and the discharge end of the partition plate 6, a The conveying roller group 7 for conveying the carrier board 2; along the conveying direction of the conveying roller group 7, the partition plate 6 is provided with a first detection station, a second detection station and a third detection station in sequence. The object loading plate 2 is used to place the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com