A device for automatic sandblasting of pipe seat molds for EMU braking systems

A technology for braking systems and EMUs, which is applied to used abrasive treatment devices, manufacturing tools, abrasive jetting machine tools, etc. Sandblasting, sandblasting comprehensive, easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

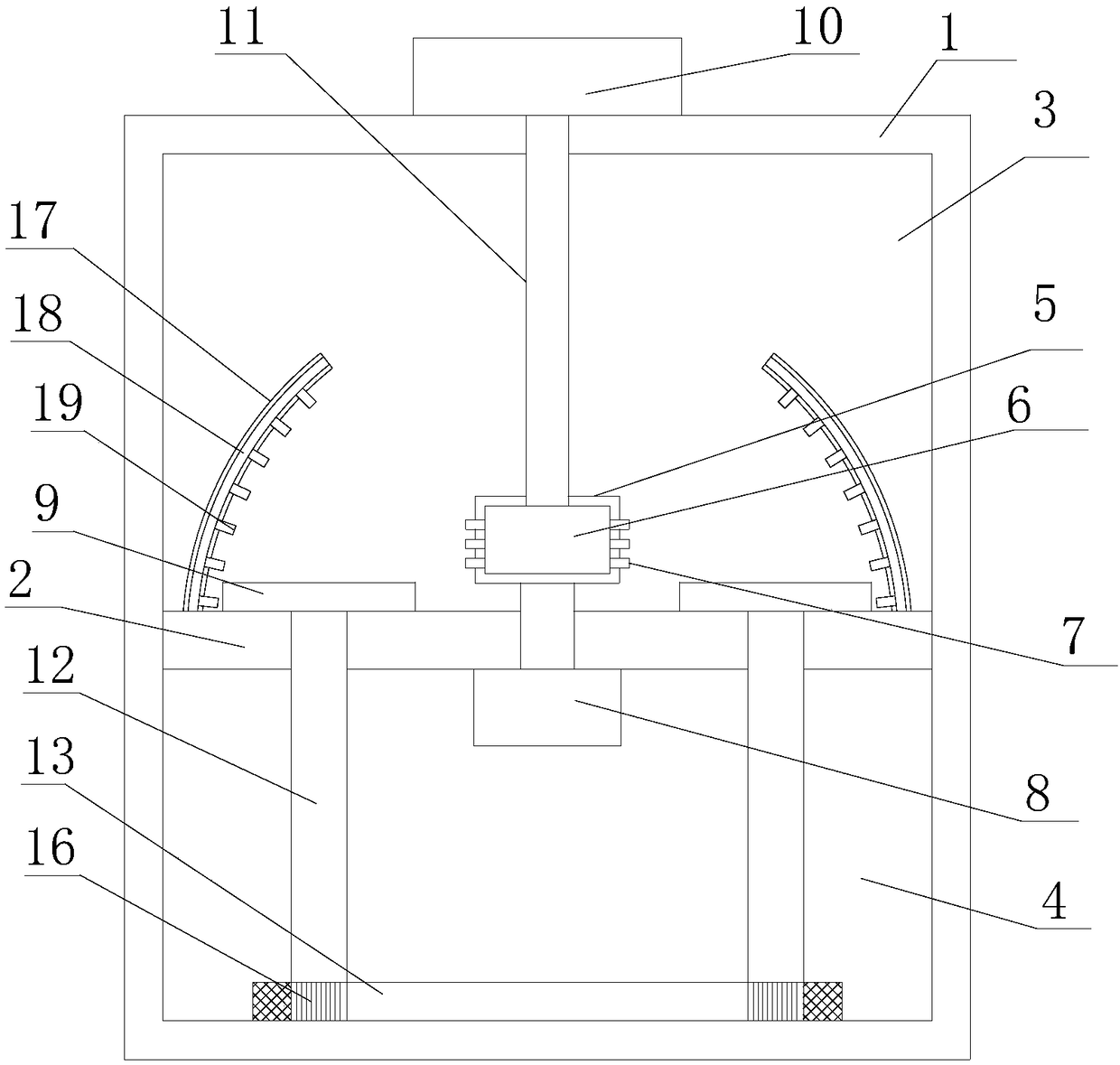

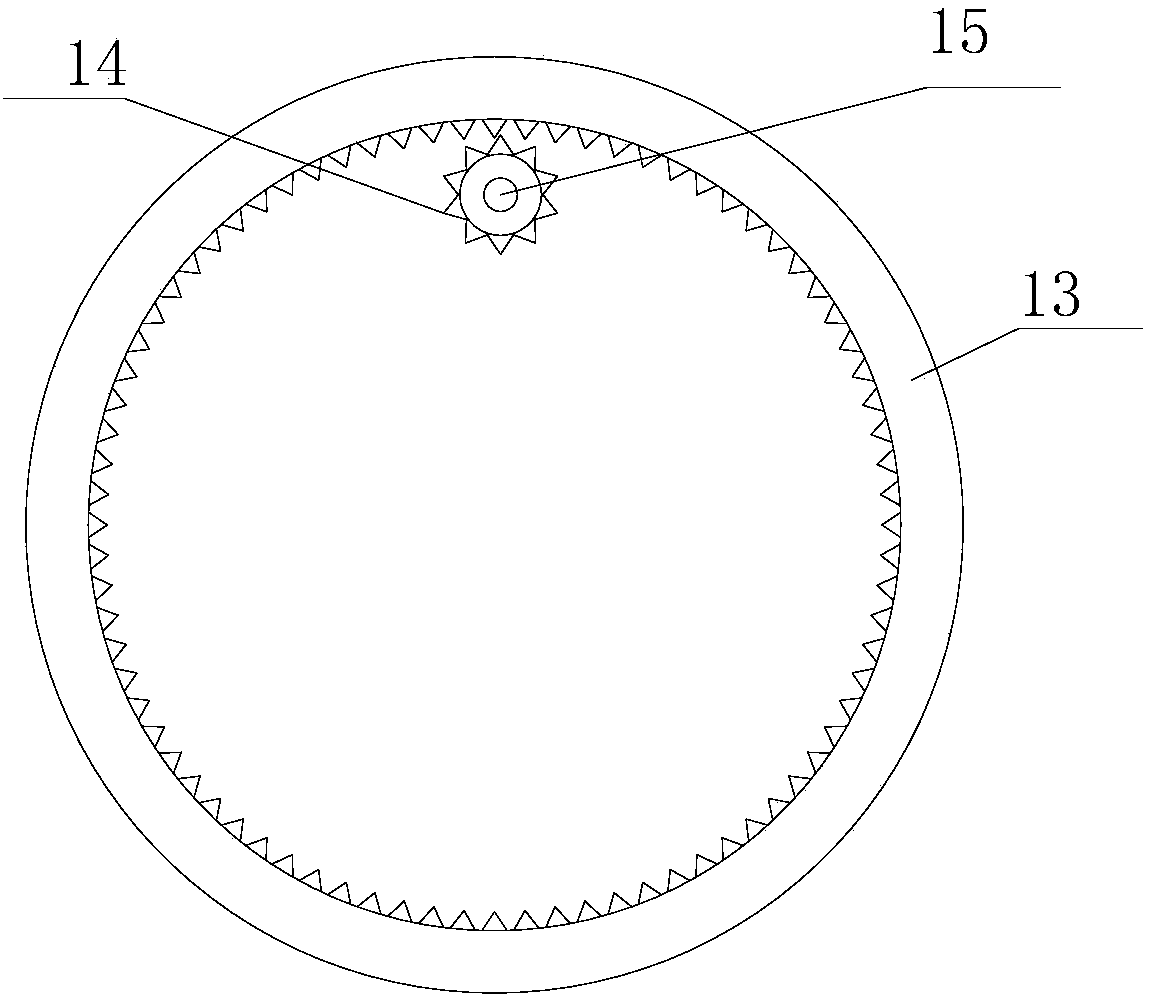

[0019] Reference figure 1 , figure 2 , The present invention proposes an automatic sandblasting device for mounting pipe seat molds of EMU brake systems, including a box body 1, a sandblasting device, a plurality of fixing devices, a first driving mechanism, a timer, and a controller, wherein:

[0020] The box 1 is provided with a transverse partition 2 which divides the interior of the box 1 into a sandblasting chamber 3 and a recovery chamber 4 from top to bottom. The transverse partition 2 is provided with meshes.

[0021] The sandblasting device includes a sandblasting box 5, a second driving mechanism 8, a sand storage box 10, and a sand guide tube 11. The sandblasting box 5 is arranged in the sandblasting chamber 3, and the sandblasting box 5 is provided with a sand storage cavity 6, which Sand blasting heads 7 are distributed around the sand box 5, and the second driving mechanism 8 is connected to the sand blasting box 5 and drives the sand blasting box 5 to rotate; one en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com