Hydraulic blasting construction method for joint fissure development rock mass tunnel

A technology of hydraulic blasting and joint fissures, which is applied in the field of tunnel blasting engineering, can solve the problems that the superiority of hydraulic blasting technology cannot be fully reflected, the loss of explosion energy transmission is large, and the efficiency of tunnel construction is low, so as to improve the utilization rate of blastholes and blasting Efficiency, improved coupling effects, uniform blasting energy transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

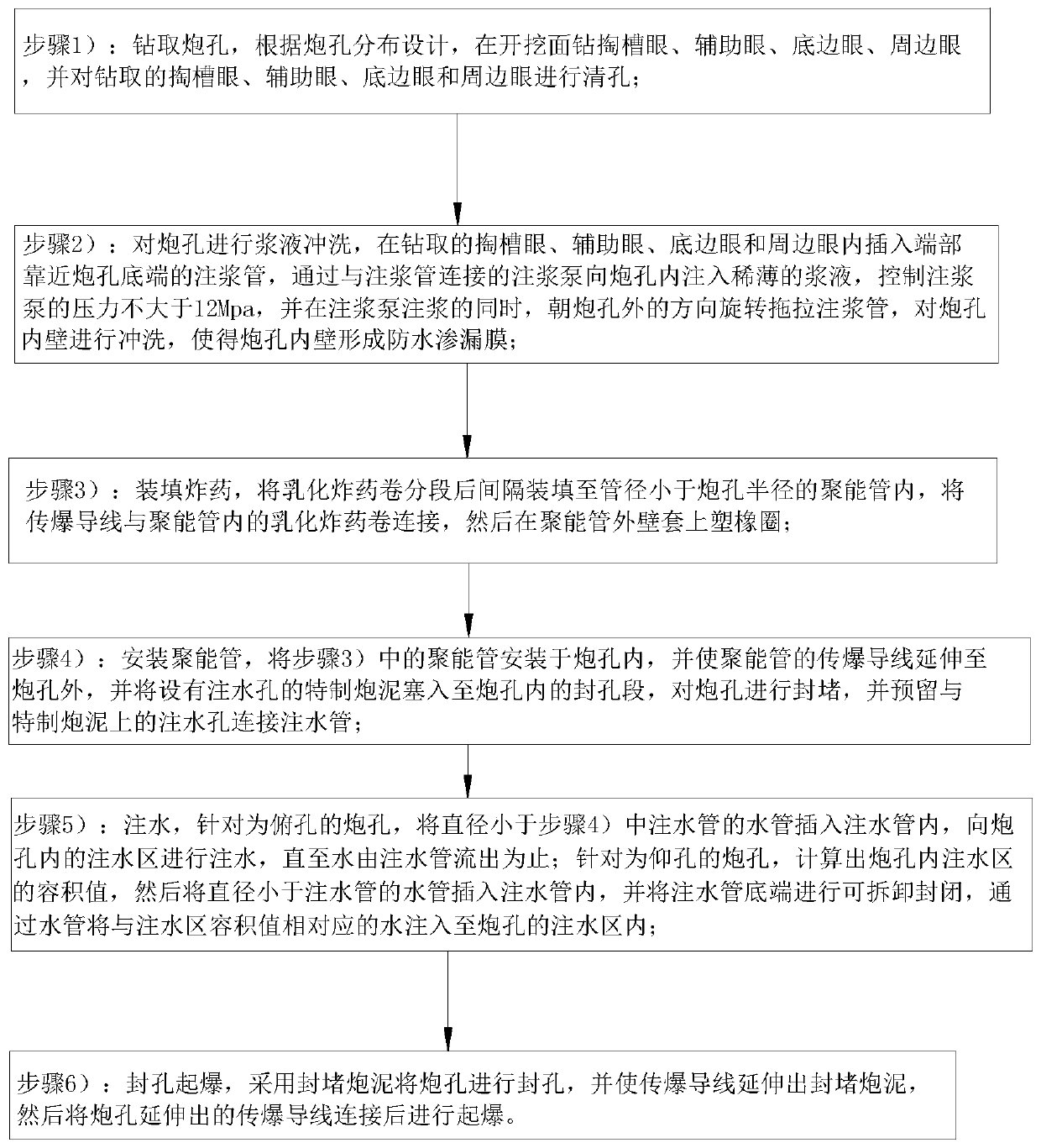

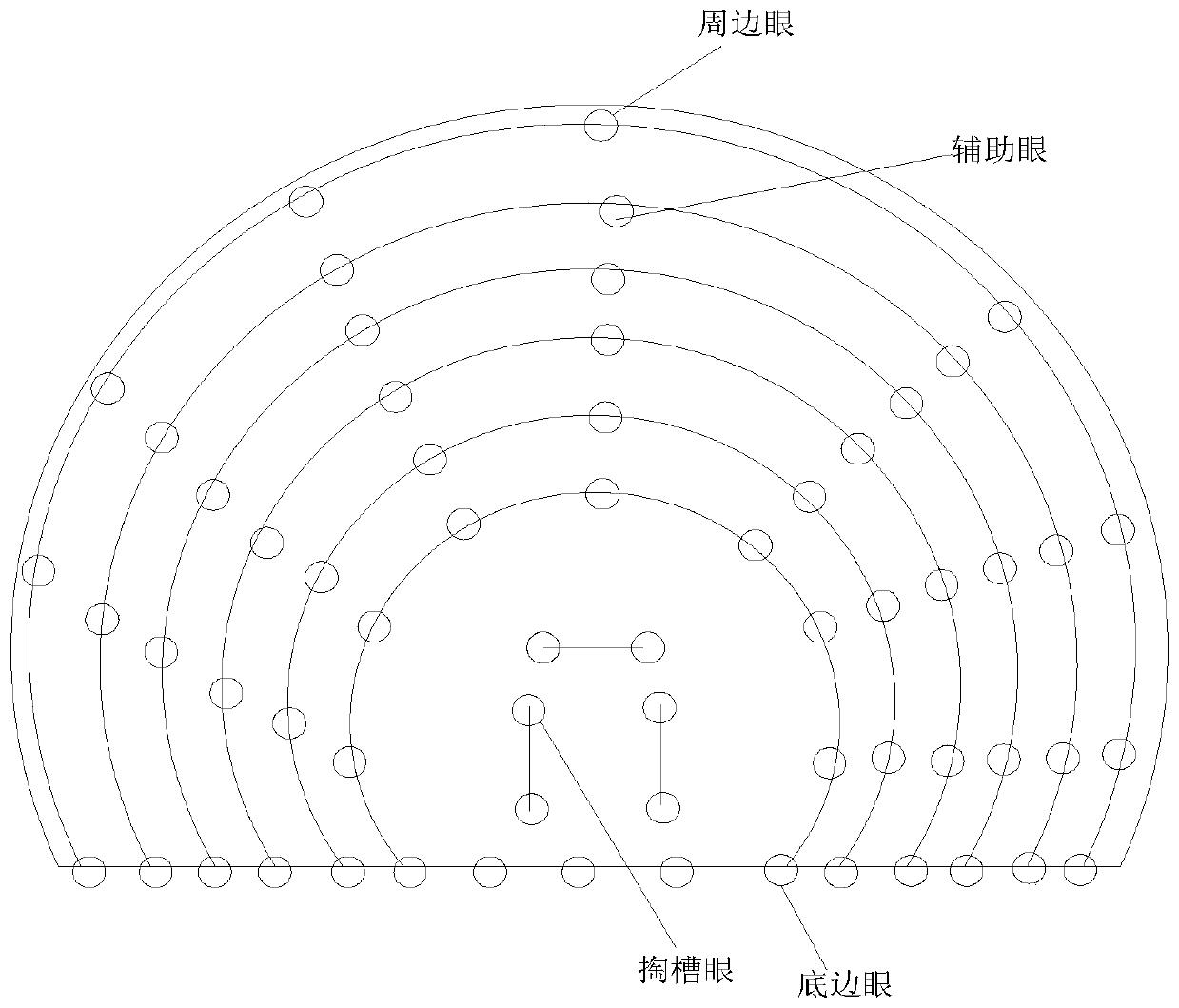

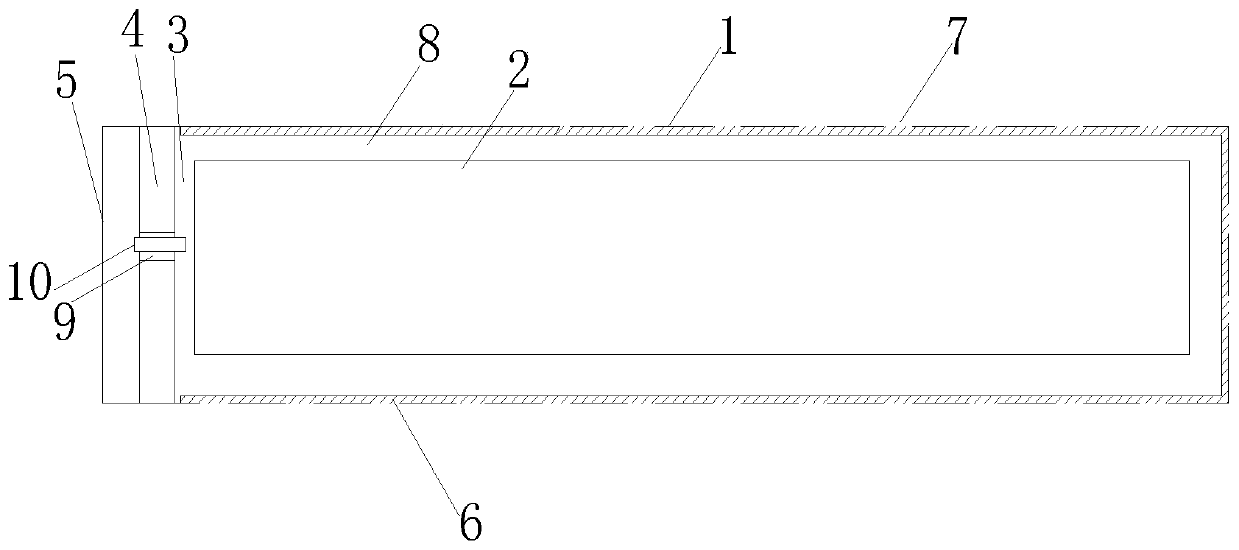

[0034] Embodiment: A kind of hydraulic blasting construction method for rock mass tunnel with joint and fissure development, such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, it specifically includes the following steps:

[0035]1) Drill the blast hole 1. According to the distribution design of the blast hole 1, drill the cut hole in the center of the excavation surface, drill the auxiliary hole outward along the cut hole on the excavation surface, drill the bottom side hole at the bottom of the excavation surface, and excavate Drill peripheral holes around the surface, and clean the drilled cutout holes, auxiliary holes, bottom edge holes and peripheral holes.

[0036] 2) Flush the blasthole 1 with grout, and insert the grouting pipe whose end is close to the bottom of the blasthole 1 into the cut holes, auxiliary holes, bottom side holes and peripheral holes drilled in step 1), and pass through the grouting pipe The connected grouting pump inje...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com