24m high step slope expansion blasting method for open pit mine

A technology of open-pit mines and steps, which is applied in the mining, blasting, earthwork drilling and mining of open-pit mines, etc. It can solve the problems of reducing the efficiency of electric shovel operations, increasing the workload of secondary blasting, and prone to large blocks, etc., so as to improve the flatness of the floor Accuracy, improvement of blasting quality, and improvement of mining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

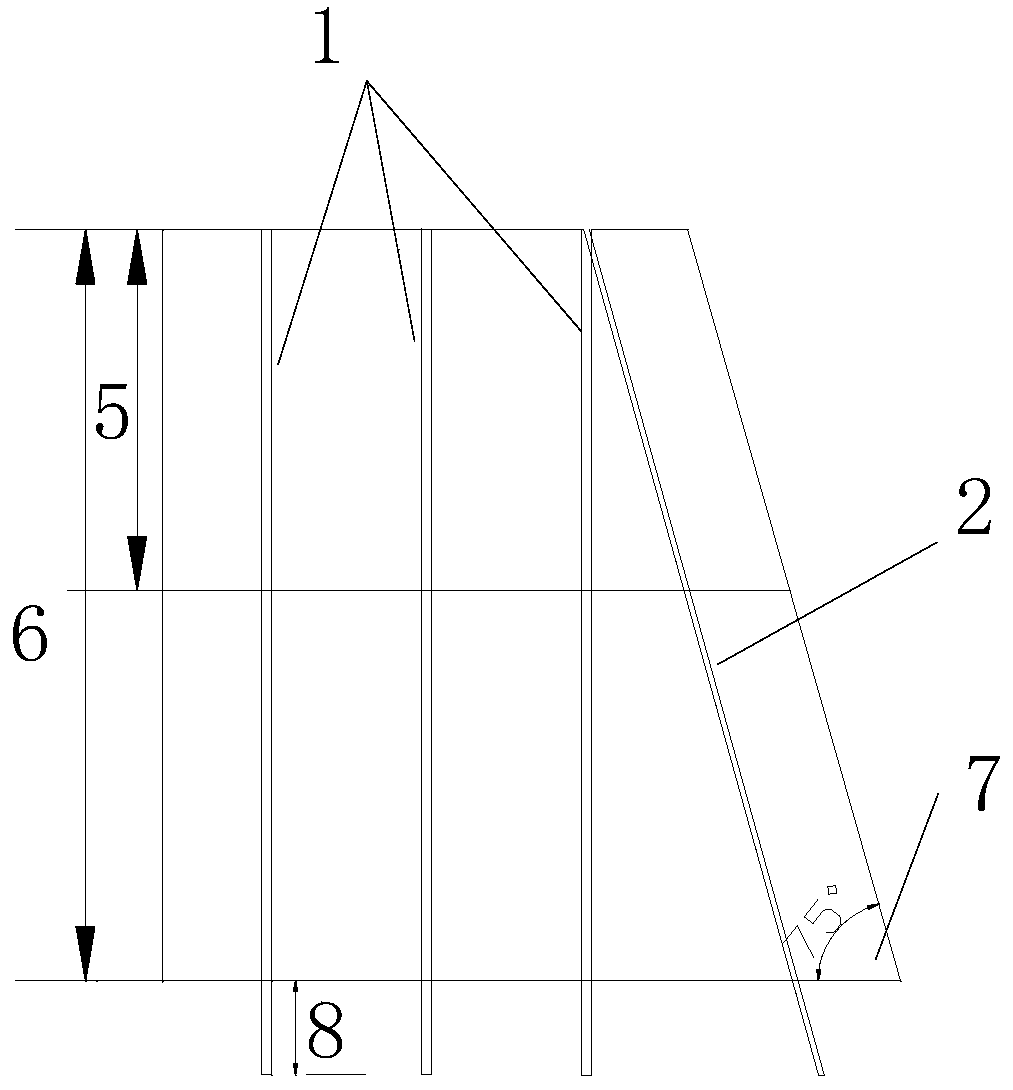

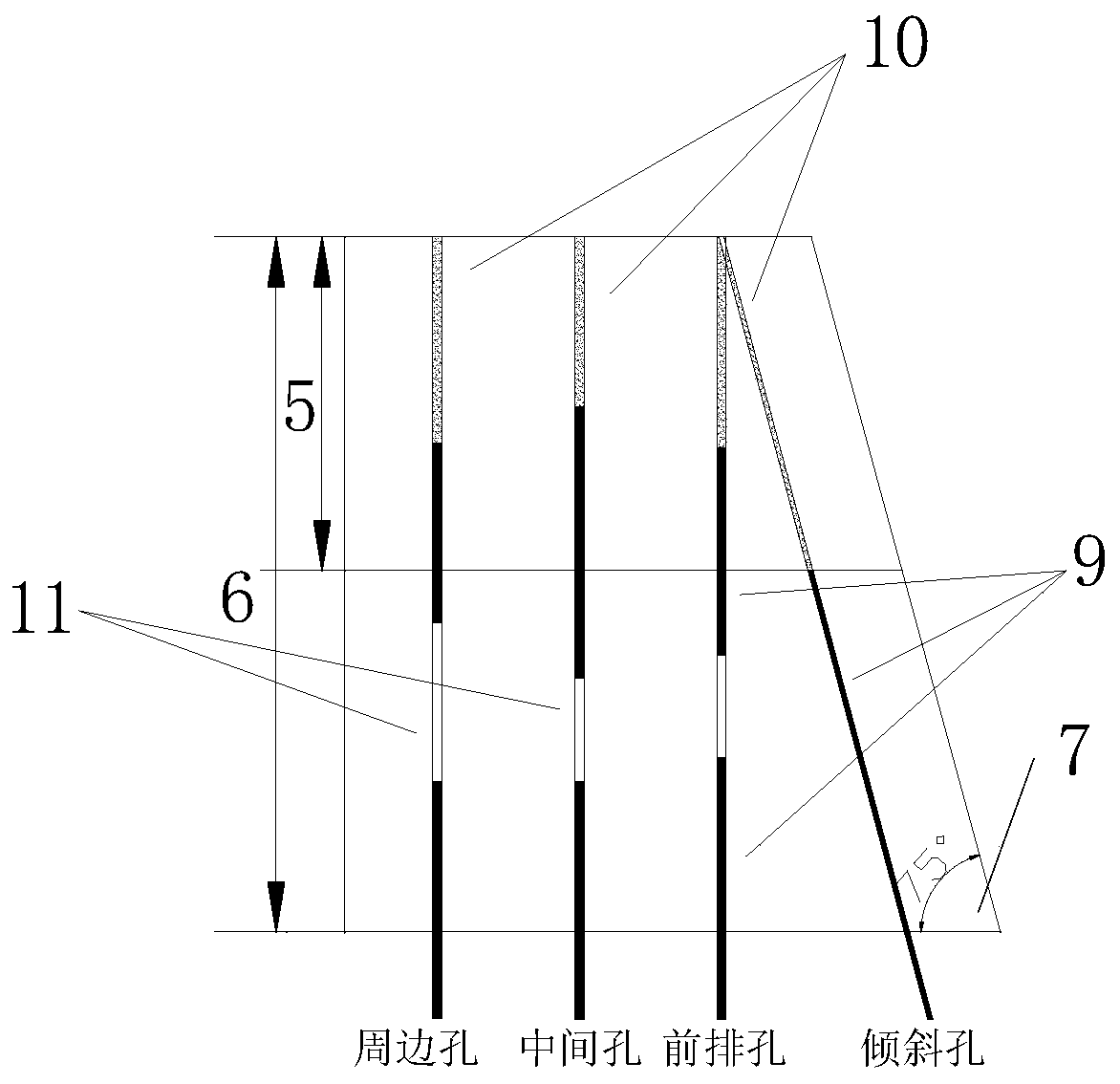

[0025] In order to overcome the large resistance line of the front row of blastholes in high-step blasting and avoid the generation of large blocks, foundations and rock walls as much as possible, this practical invention proposes to use the hole diameter Holes are laid out in the joint operation of 310mm roller cone drilling rig and 165mm hole diameter down-the-hole drilling rig. The specific measure is to add 3-4 165mm inclined holes parallel to the step slope in the middle of the two front row 310mm vertical holes. This method effectively reduces the front row resistance line of high step blasting and ensures the drilling rig to the greatest extent. Perforation efficiency to rationalize blasting economy.

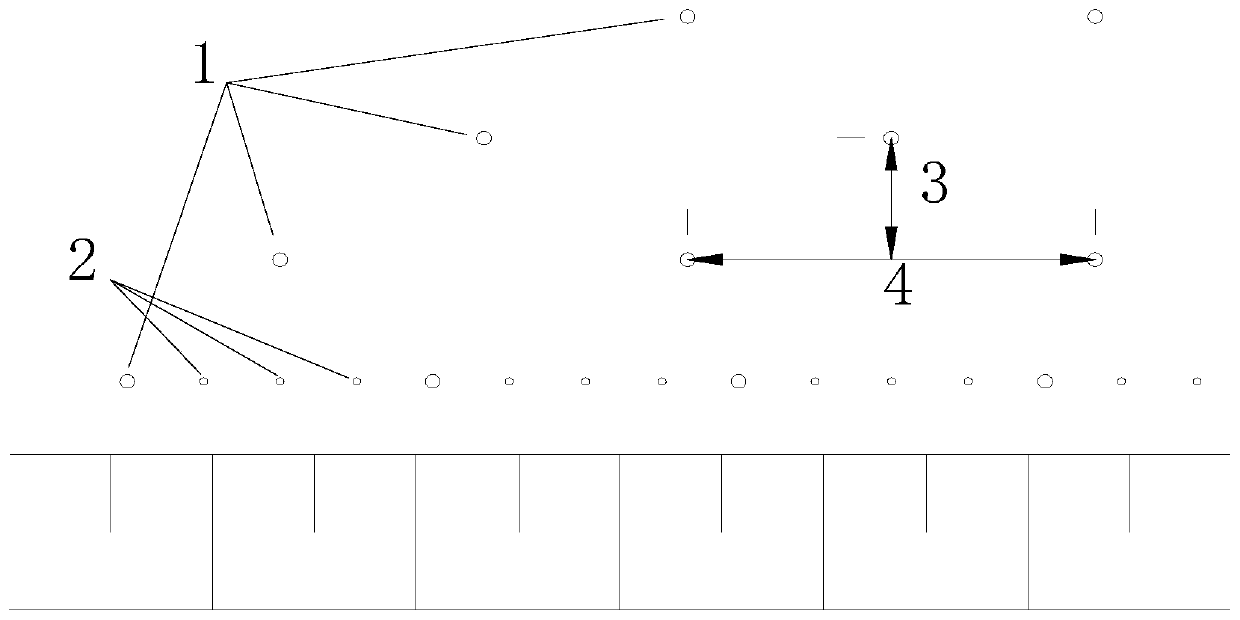

[0026] Specific implementation steps (refer to figure 1 , figure 2 and image 3 ):

[0027] Ⅰ. First plan the blasting area in the area to be blasted in the merged section, and arrange blasting holes on the site according to the planned technical parameters according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com