Spraying gun

A technology of spray guns and nozzles, which is applied in the field of hydraulic spray tools and spray guns, and can solve the problems of spray gun body backsplash damage, poor anti-splash ability, spray gun body damage, etc., to achieve strong anti-splash ability and avoid being stabbed , long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

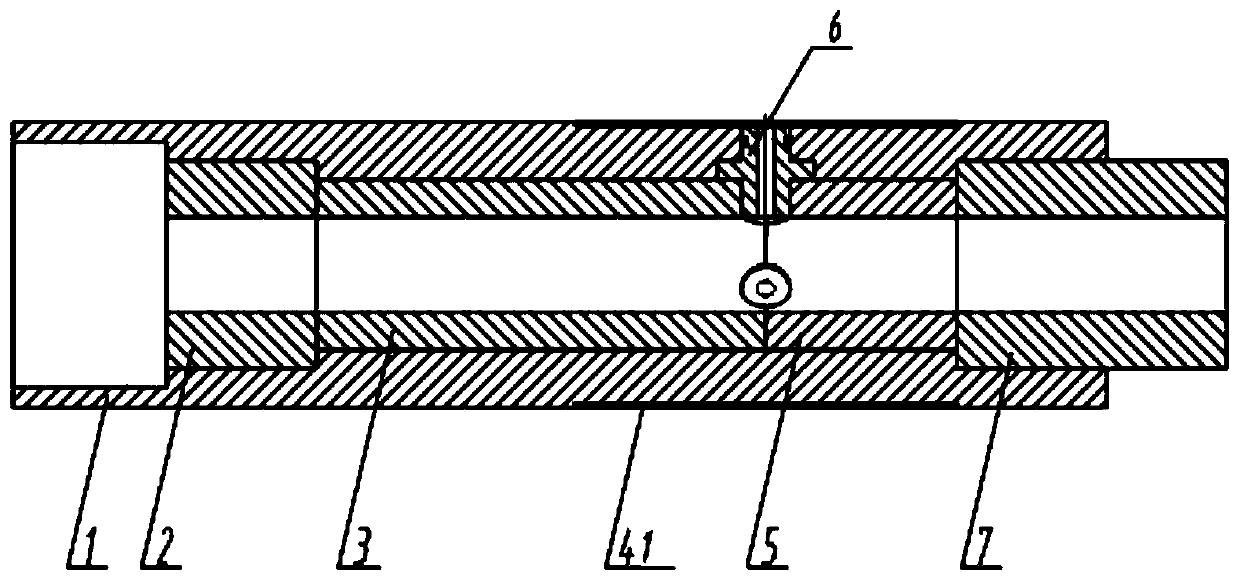

[0031] like figure 1 As shown, in this embodiment, the spray gun mainly includes a spray gun body 1 , a fixed joint 2 , an upper inner tube 3 , a superhard coating 41 , a lower inner tube 5 , a nozzle 6 , and a lower joint 7 . The spray gun body 1 has a stepped hole for assembling the nozzle 6. The end of the stepped hole near the inner wall of the spray gun body 1 is a large diameter end, and the end near the outer wall of the spray gun body 1 is a small diameter end; the middle part of the nozzle 6 is formed with holes for In order to realize the communication between the inner cavity of the spray gun body 1 and the outside, a boss is also formed in the middle of the outer wall of the nozzle 6, wherein the part of the nozzle above the boss is matched and inserted in the small diameter end of the stepped hole, and the boss is matched and inserted in the stepped hole. In the large-diameter end of the hole; the upper inner tube 3 and the lower inner tube 5 are coaxially inserte...

Embodiment 2

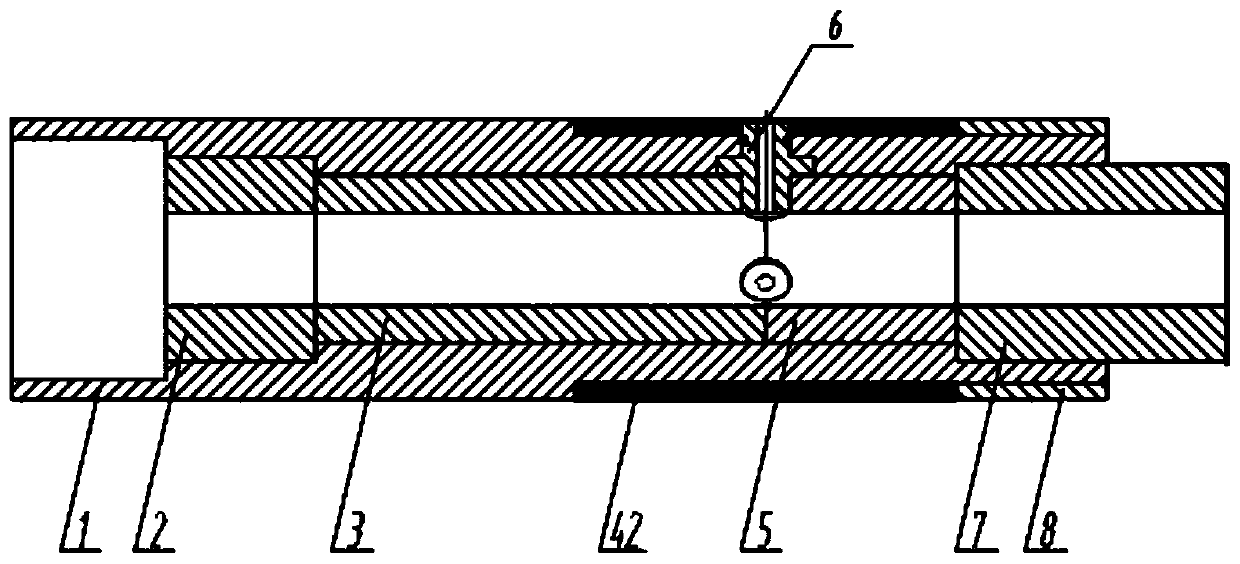

[0038] like figure 2 As shown, the difference between the second embodiment and the first embodiment is that the superhard coating 41 is replaced by a superhard alloy cylinder 42 and a stopper 8 .

[0039] In this embodiment, turning is performed on the side of the outer wall of the spray gun body 1 close to the lower joint 7, and a step is turned in the middle of the outer wall of the spray gun body 1, and the superhard alloy barrel 41 is matched with the turning surface of the spray gun body 1. On the surface, and one end of the superhard alloy cylinder 41 is on the step; the stopper 8 is a ring structure and it is matched with the end of the turning surface of the spray gun body 1, and is supported on the other end of the superhard alloy cylinder 41, To tighten the superhard alloy cylinder 41 on the step to realize the limited assembly of the superhard alloy cylinder 41 and the spray gun body 1, wherein the stopper 8 and the spray gun body 1 are connected by threads or fix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com