Blasting method capable of improving step deep-hole blasting quality by using auxiliary blasthole

A technology of deep hole blasting and blast hole, which is applied in the field of blasting, and can solve problems such as high large block rate and affect the normal operation of mine production, and achieve the effects of reducing large blocks, improving blasting quality, and increasing energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below:

[0020] A blasting method that uses auxiliary blast holes to improve the quality of stepped deep hole blasting. The method follows the following steps:

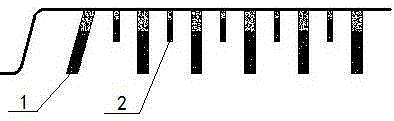

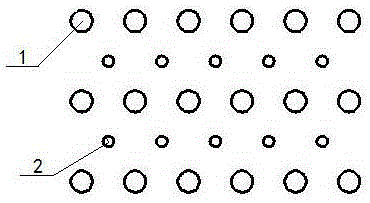

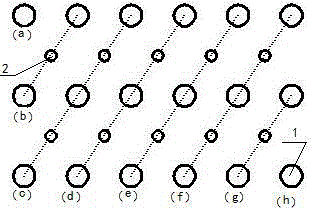

[0021] The first step, such as figure 1 , figure 2 As shown, on the steps of the blasting zone, the main blasting hole 1 with a diameter of 80mm or more is drilled according to the matrix layout method. The main blasting hole 1 is set at the front of the step and the vertical setting at the rear of the step. Steps in the blasting zone. The first 1-3 rows of the steps in the blasting zone use inclined blast holes, and the main blast hole 1 and auxiliary blast hole 2 in the back row use vertical holes; other blasting parameters of the main blast hole 1 are in the design and construction Follow the normal stepped deep hole blasting design and construction principles;

[0022] The second step is to drill the auxiliary blast hole 2 with a diameter of 75mm in the middle betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com