Slope expansion and blasting method for mining deep concave open-pit mine by stages

A technology of open-pit mines and deep holes, which is applied in blasting, ground mining, earthwork drilling and mining, etc. It can solve the problems of endangering the safety of equipment and transportation lines, reducing the production efficiency of electric shovels, and greatly affecting the organization, so as to reduce the front impact of blasting distance, guarantee mine production capacity, effect of reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

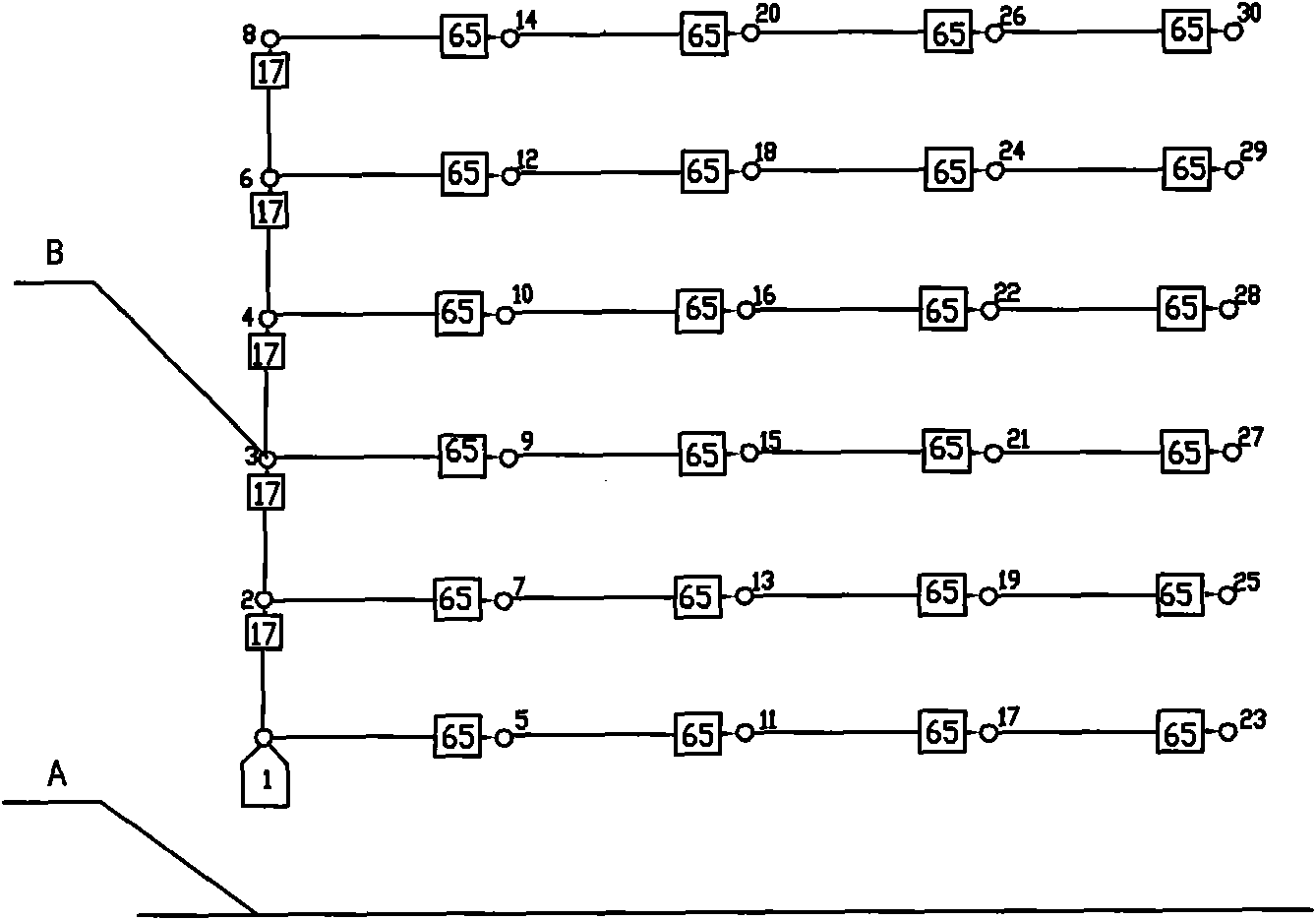

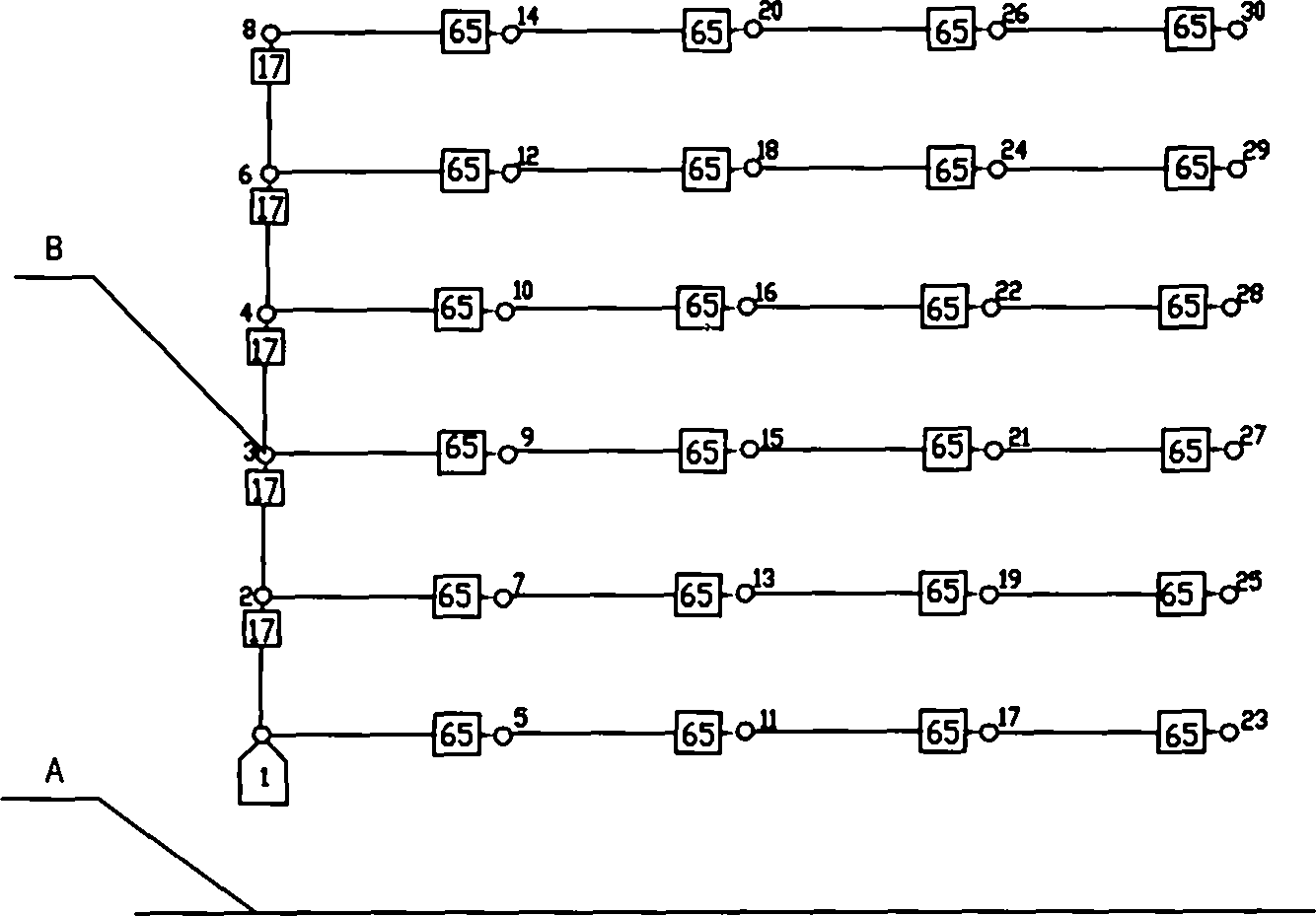

[0039] Under the condition that the width of the side expansion part is greater than 20 meters, a method of side expansion blasting in deep concave open-pit mining by stages is adopted, including the design of deep hole layout, perforation construction, setting detonators in deep holes, and loading explosives in deep holes Construction, carrying out the delayed detonation design of the surface network detonator, connecting and detonating the detonator in the blast hole and the surface network detonator, characterized in that:

[0040] 1) In the above-mentioned deep hole layout design, the blasting area control blast hole B is designed to be perpendicular to the slope top line A of the main stope, and the blast hole layout is 5 rows and 6 columns. The hole diameter of the deep hole layout design is 200mm, the hole spacing is 7.5m, the row spacing is 7.5m, and the hole depth is 15m.

[0041] 2) In the delayed detonation design of the surface network detonator, the detonation seq...

Embodiment 2

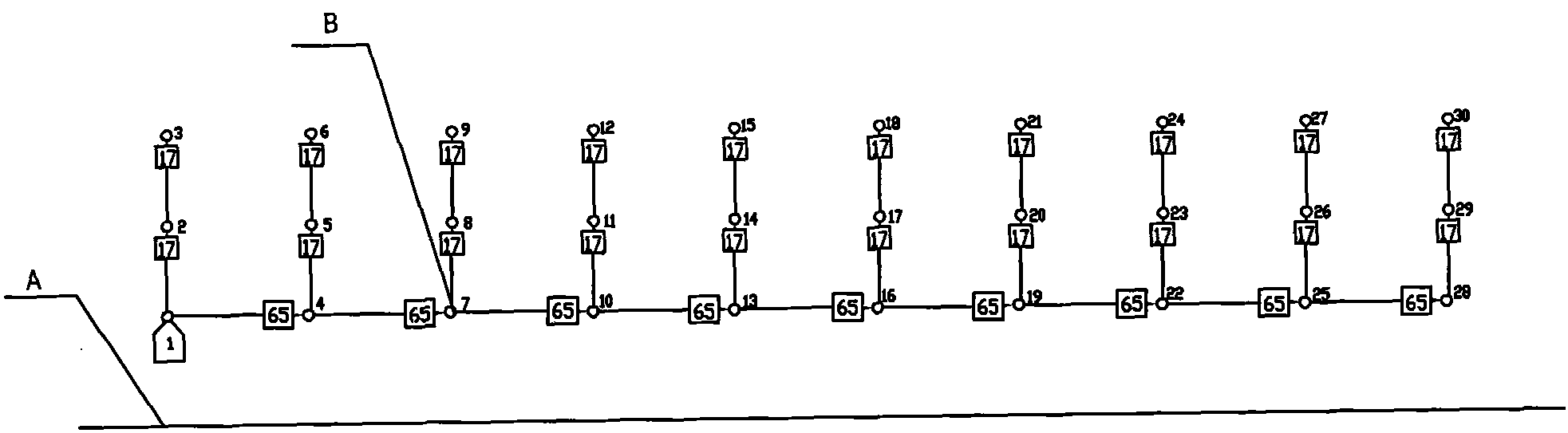

[0044] Under the condition that the width of the side expansion part is less than 20 meters, a method of side expansion blasting in deep concave open-pit mining by stages is adopted, including the design of deep hole layout, perforation construction, setting detonators in deep holes, and loading explosives in deep holes Construction, carrying out the delayed detonation design of the surface network detonator, connecting and detonating the detonator in the blast hole and the surface network detonator, characterized in that:

[0045] 1) In the above-mentioned deep hole layout design, the blasting area control blast hole B is designed to be parallel to the slope top line A of the main stope, and the blast hole layout is 3 rows and 10 columns. The hole diameter of the deep hole layout design is 200mm, the hole spacing is 7.5m, the row spacing is 7.5m, and the hole depth is 15m.

[0046] 2) In the delayed detonation design of the surface network detonator, the detonation sequence i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com