High-wave resistance orientation resistance sliding combination energy dissipation body applied to rock foundation excavation forming

A basic, high-wave technology, applied in the field of high-wave impedance directional sliding combined energy dissipation body, can solve the problems of weak actual reflection energy dissipation effect, affecting field operability, downward emission of explosive stress waves, etc., to ensure the control of hole bottom damage depth, ensure the quality of excavation, and increase the effect of lateral blasting and crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation of the high wave impedance directional sliding combined energy dissipation body suitable for rock foundation excavation and formation according to the present invention will be described in detail below with reference to the accompanying drawings.

[0024]

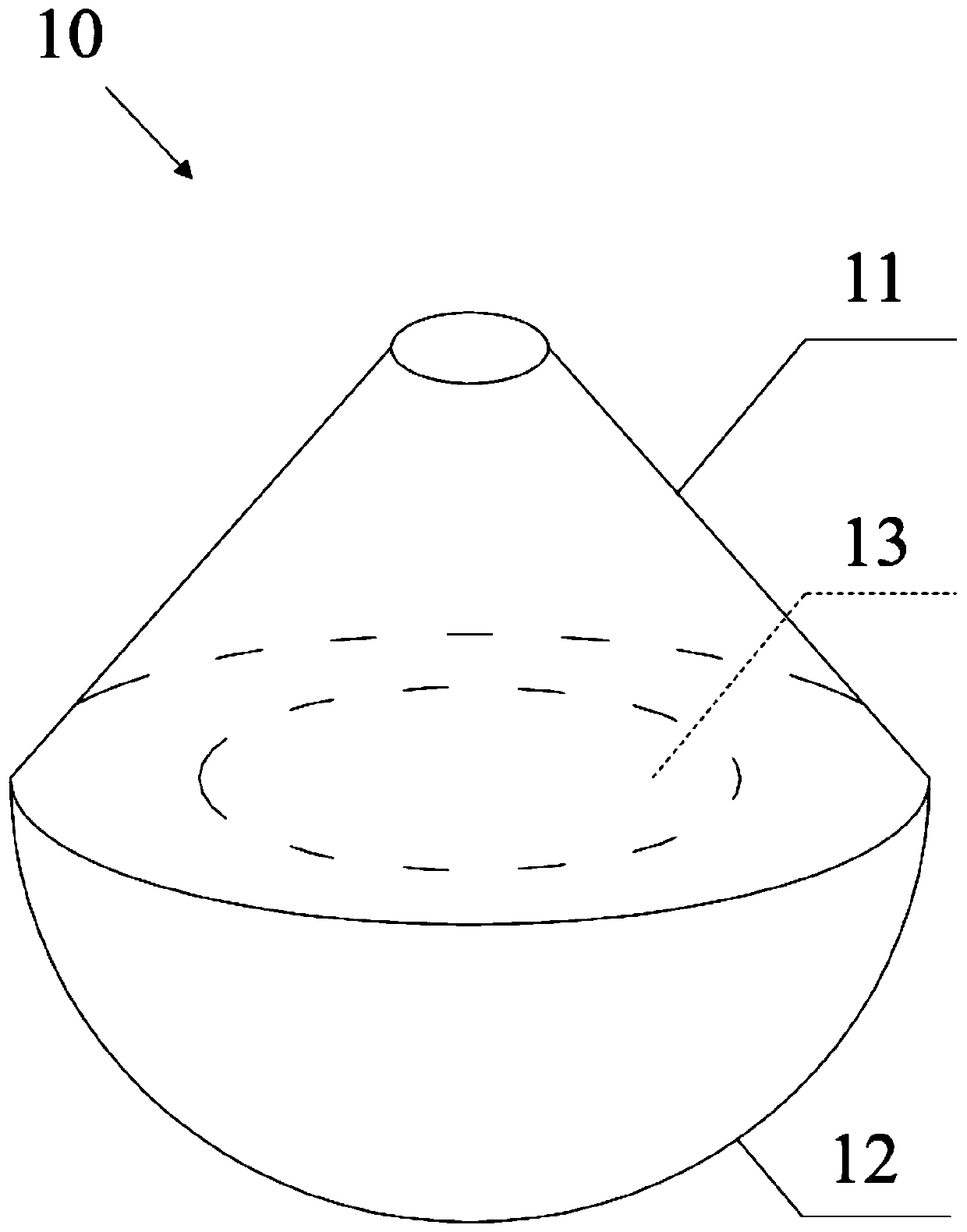

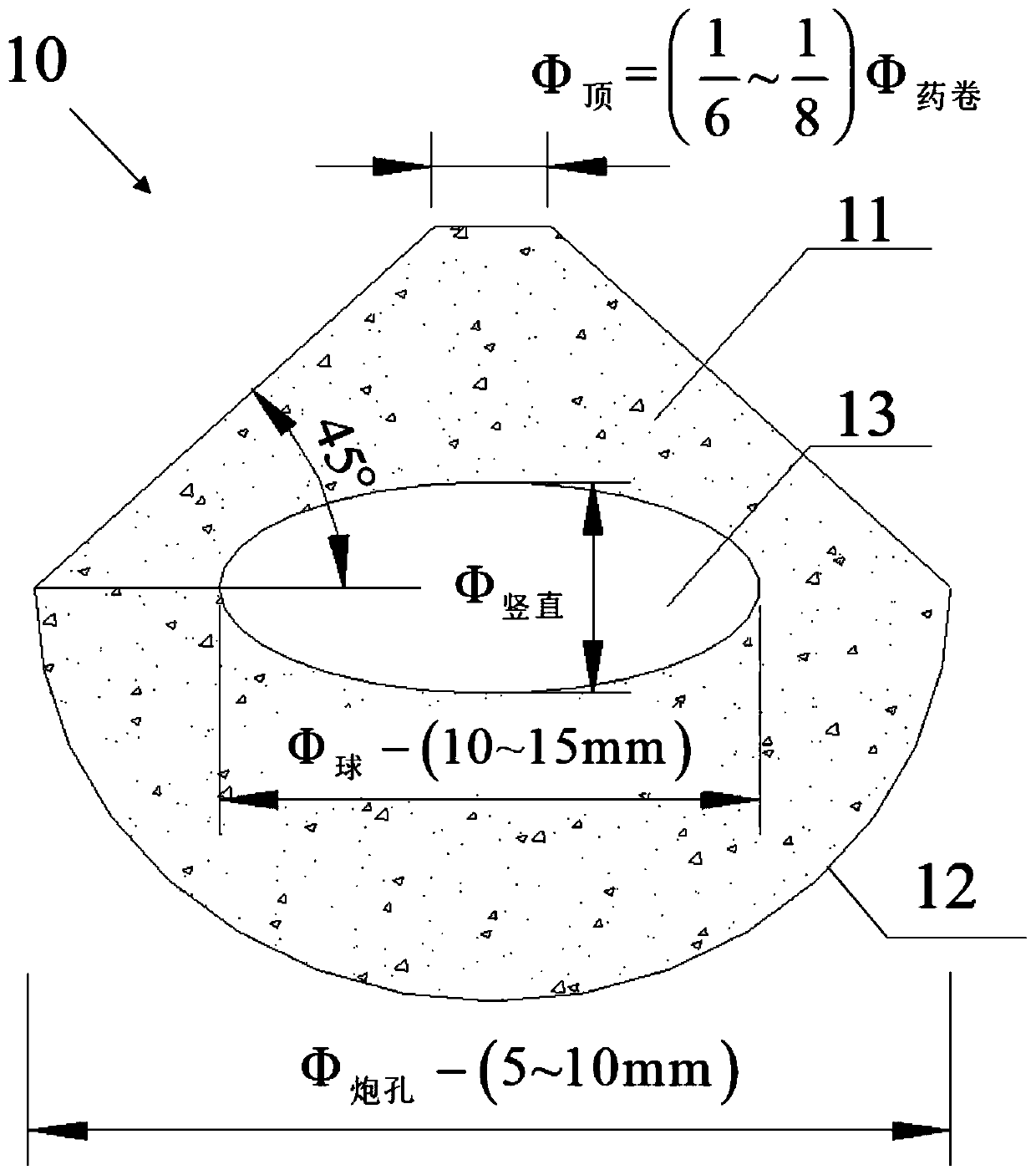

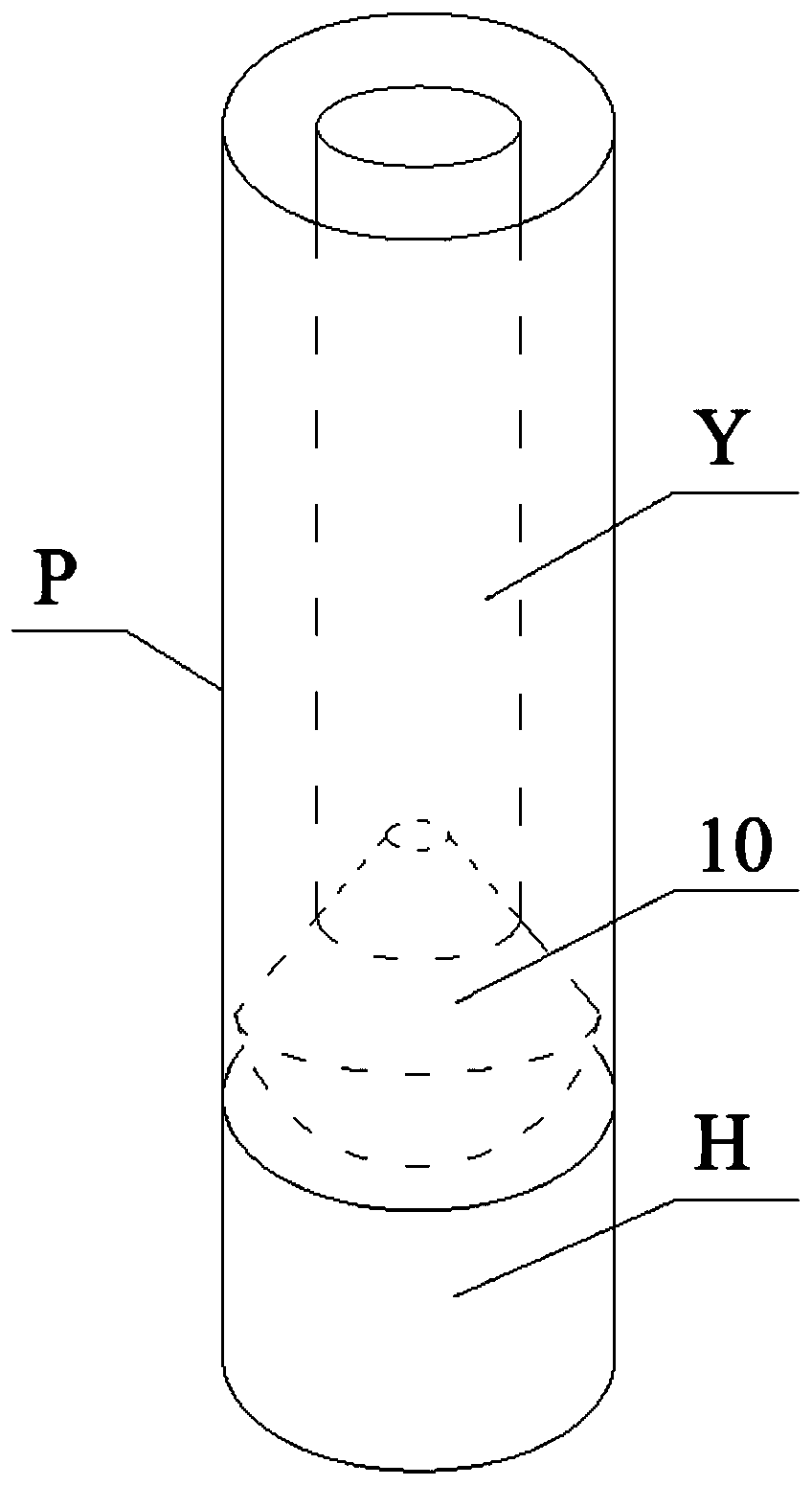

[0025] Such as Figures 1 to 4 As shown, the high wave impedance directional sliding combined energy dissipation body 10 suitable for rock foundation excavation and formation provided by this embodiment includes a circular frustum 11 (conical truncated cone), a hemispherical body 12 and a flat air-filled cavity 13 .

[0026] The busbar of the round table 11 forms an angle of 45° with the bottom surface, and the diameter of the bottom surface of the round table 11 is Φ 底 = Φ 炮孔 -(5~10mm), the diameter of the top surface is where Φ 炮孔 is the diameter of blasthole P, Φ 药卷 is the diameter of the drug roll Y.

[0027] The upper surface of the hemisphere 12 is fixedly combined with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com