Large-area quartz wafer grinding device and grinding method

A technology for quartz wafers and grinding devices, which is applied in the direction of grinding devices, grinding machine tools, and parts of grinding machine tools, and can solve problems such as damage to thin substrates, increased resistance, and large diameter-to-thickness ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

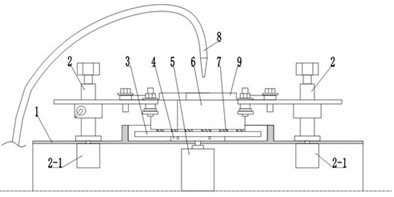

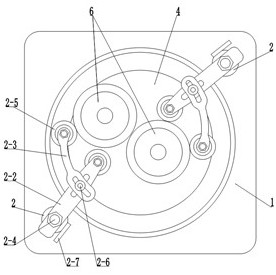

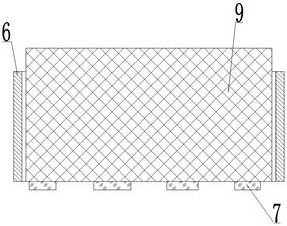

[0040] See Figure 1, figure 2 , image 3 , Figure 4 , the large-area quartz wafer grinding device of the present invention is provided with a base 1, a support arm assembly 2, a grinding disc 3, a rotating seat 4, a rotating motor 5, a loading block 9, a repairing ring 6 and a dropper; The pedestal 1 is a square pedestal arranged on a horizontal plane, and support arm assemblies 2 are installed at both ends of the diagonal line of the pedestal 1, and a drop feeder is arranged on the platform behind the base 1; the drop feeder The discharge port of drip tube 8 is located above the central position of grinding disc 3; 4 is provided with three sets of positioning holes matched with positioning pins; the rotating seat 4 is driven by the rotating motor 5; Several groups of quartz wafers 7 .

[0041] see figure 2, the large-area quartz wafer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com