Drill jumbo blast hole laser ranging and positioning method

A technology of laser ranging and rock drilling rig, applied in the field of laser measurement, can solve the problems of complex state, large positioning error, uneven positioning section, etc., and achieve the effect of high work efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

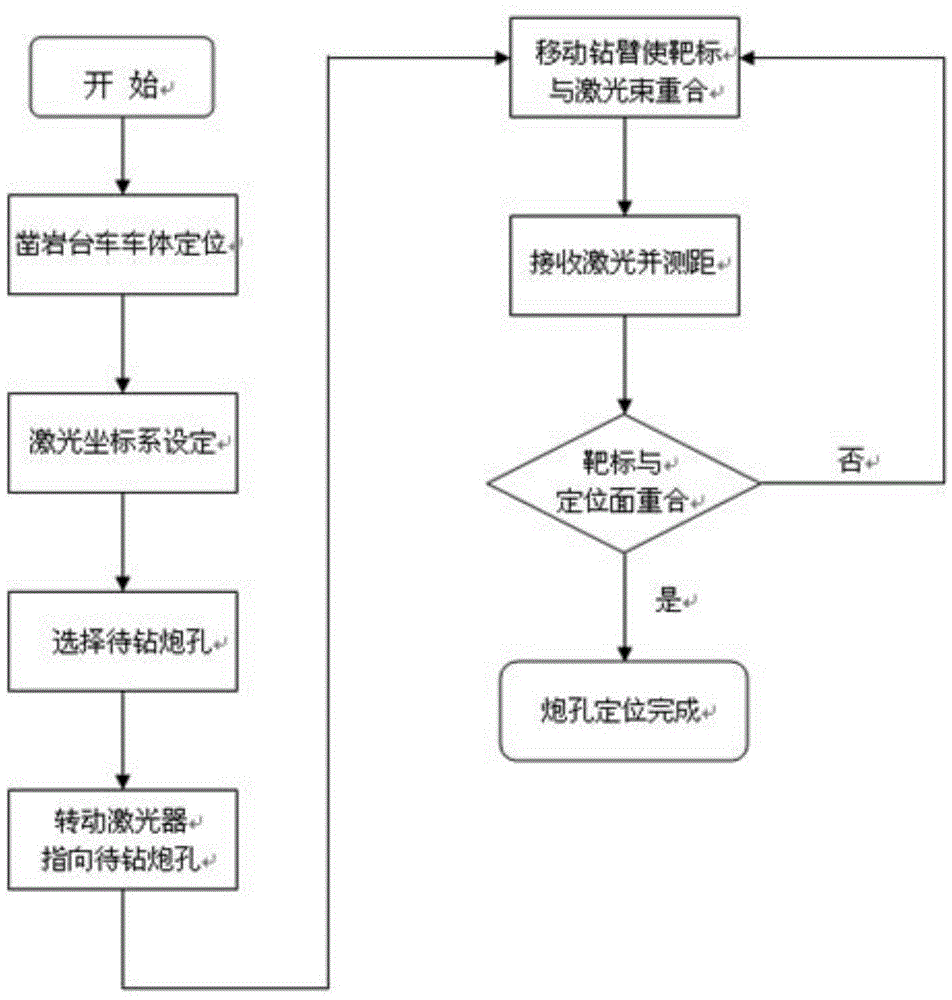

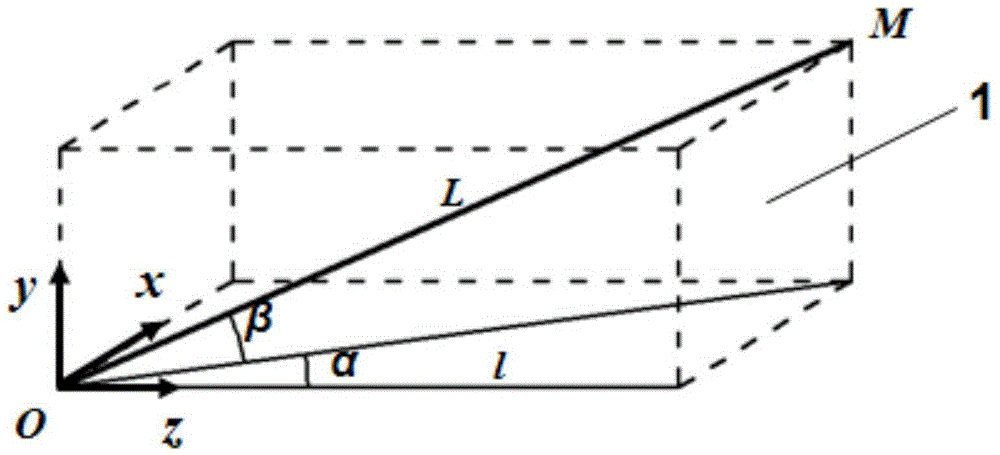

[0021] The specific implementation manners of the present invention will be further described below in conjunction with the technical solutions of the present invention and the accompanying drawings.

[0022] The positioning equipment used in the present invention includes an industrial laser ranging sensor, a laser target, a high-precision omnidirectional pan-tilt and a touch screen PLC integrated machine. The rock drilling jumbo is a tunneling type rock drilling jumbo.

[0023] The industrial laser ranging sensor is installed on the high-precision omni-directional pan / tilt, and the high-precision omni-directional pan / tilt is suspended and fixed directly below the central axis of the ceiling of the rock drilling rig operating room, and is connected with the touch screen PLC integrated machine. The industrial laser ranging sensor It is connected with the touch screen PLC all-in-one machine through the data interface; the laser target is installed on the bracket at the front en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com