Method for implementing full-face smooth blasting construction by using digital detonators

A technology of smooth blasting and construction methods, applied in blasting and other directions, can solve problems such as poor blasting quality, and achieve the effects of increasing cyclic footage, obvious blasting vibration control, and significant social and economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

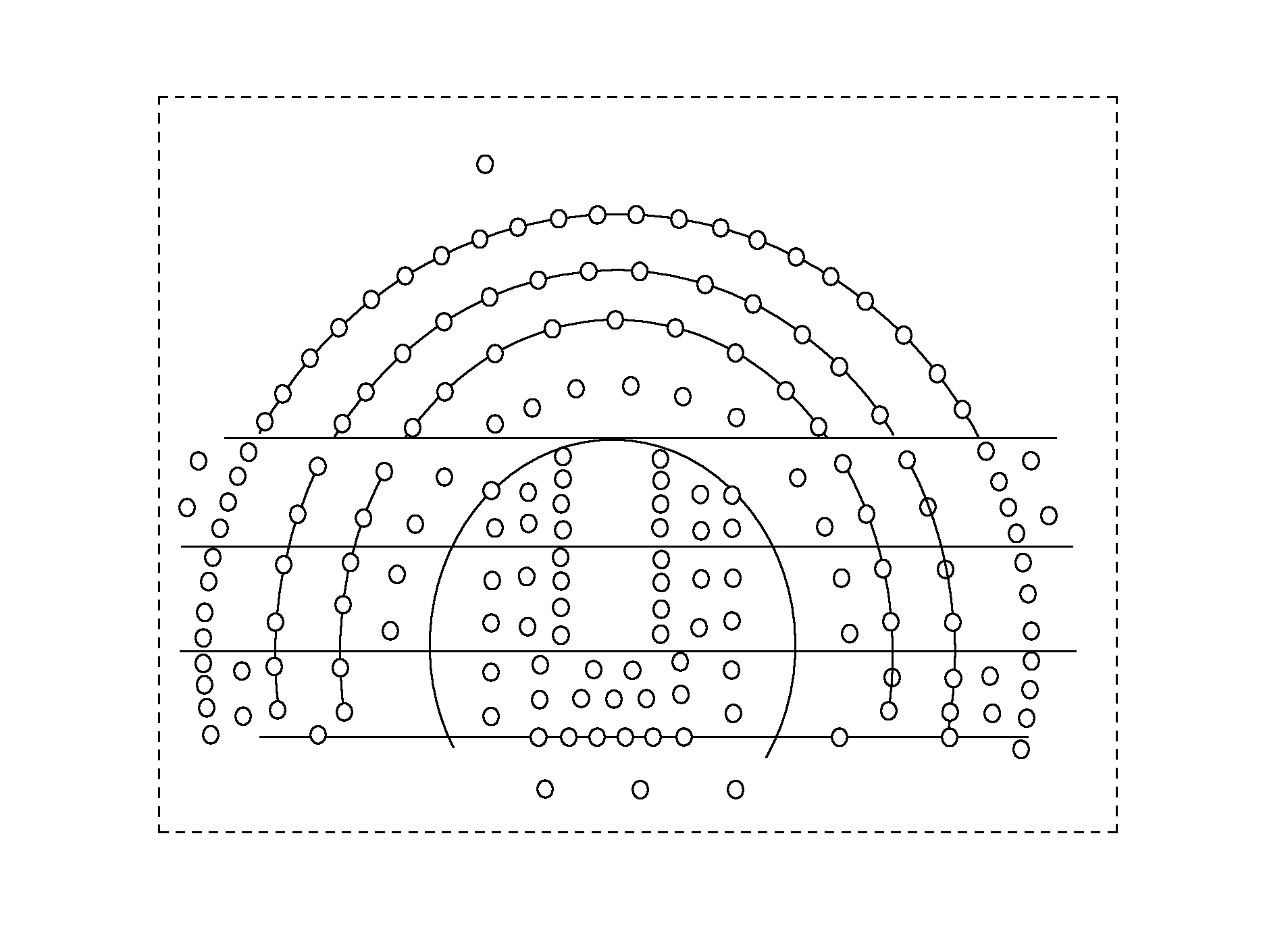

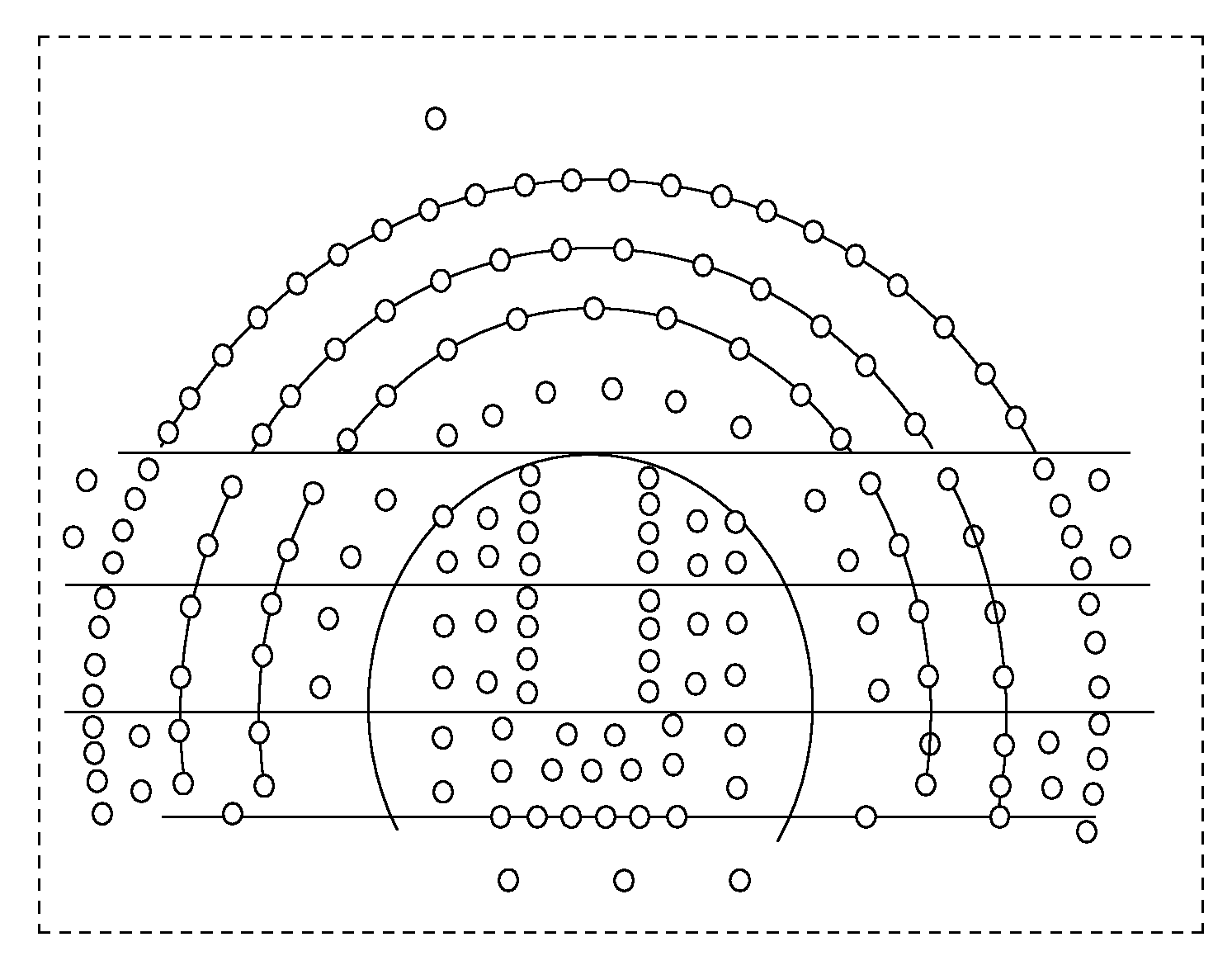

Image

Examples

example

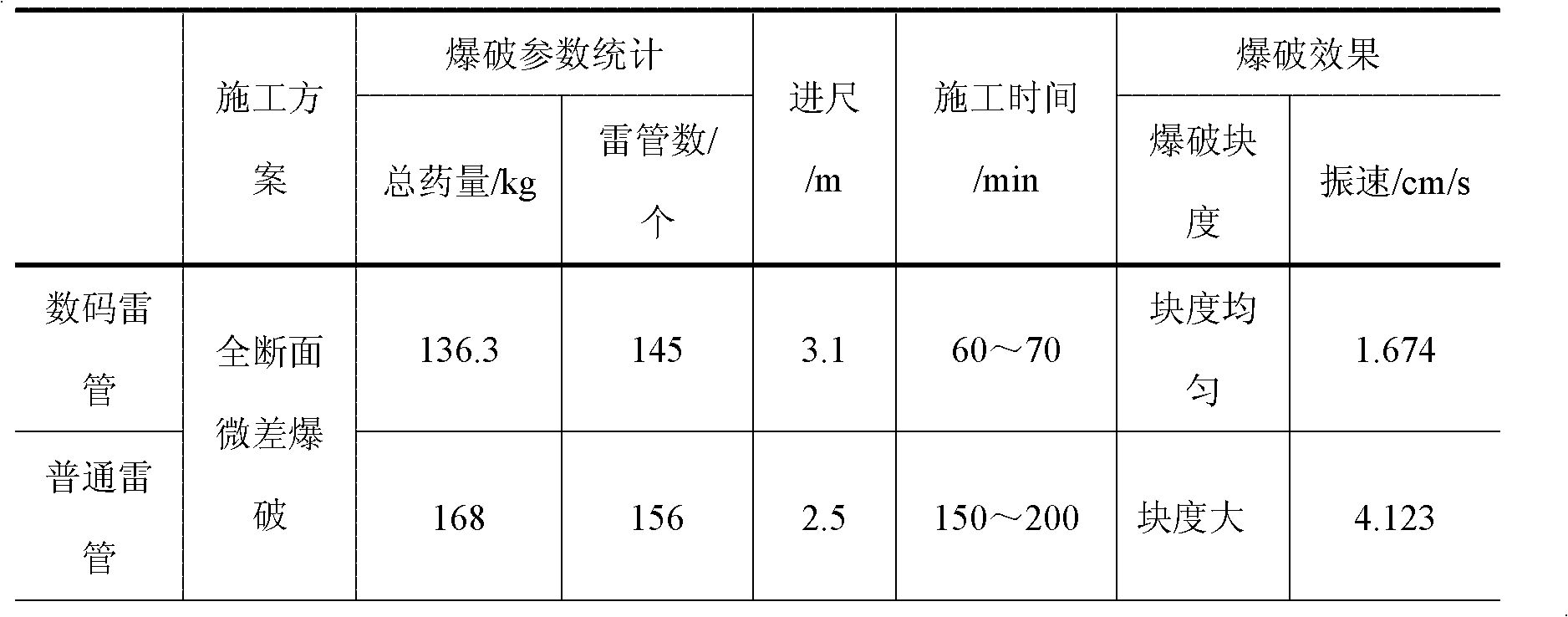

[0027] In 2010, the excavation and blasting of tunnels in the XX area was carried out using the following plan: (1) Cycle footage: set according to geological conditions, for example, the blast footage per cycle is 1.5-2.5m, with an average footage of 2.0m. (2) Blasting equipment: No. 2 rock emulsion explosives are used as explosives, and "Longxin No. 1" digital detonator and iridium bowl initiation system are selected. (3) Cutting method: V-shaped cutting is adopted, the depth of the cutting blasthole is 3.0-3.3m, and the depth of other blastholes is 2.7-2.8m. The detonating cord is 3m. (4) Charge structure: the blast hole diameter is 42cm, the charge diameter is 25cm, the uncoupled charge structure is adopted, the peripheral eyes all adopt the form of spaced charges, and the uncoupled ratio n=1.68. (5) Delay time design: The delay time of the digital detonator is 693ms, the time interval of the micro-difference blasting of the slot eye is 3ms, the initiation time interval o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com