Multifunctional fabricated hydraulic drive moveable trestle

A mobile trestle and prefabricated technology, used in shaft equipment, shaft lining, mining equipment, etc., can solve problems such as affecting the project cycle and quality, difficult to guarantee safety, mutual interference or conflict, etc., to achieve strong adaptability and construction efficiency. High, anti-overload effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

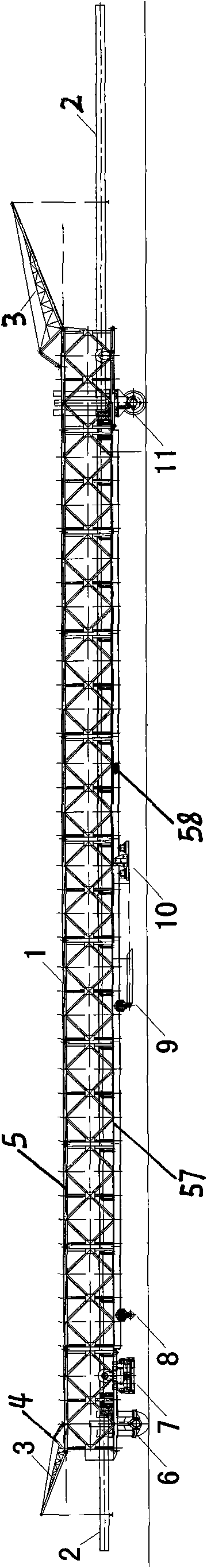

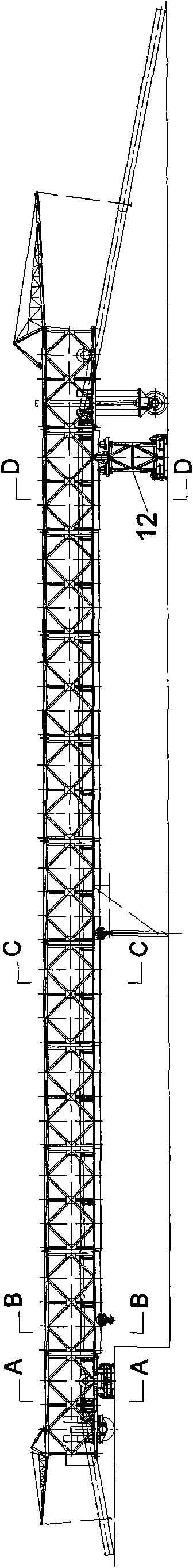

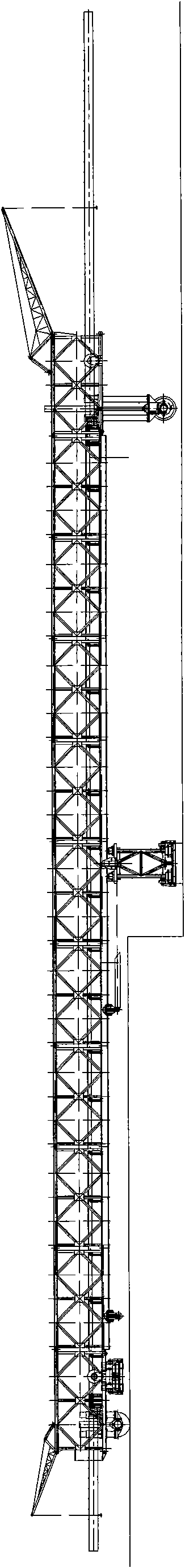

[0026] see Figure 1-Figure 4 , the present invention comprises a main bridge 1 and approach bridges 2 positioned at two ends of the main bridge 1, as well as a hydraulic system and an electrical system. The main bridge 1 includes a beam 59 and trusses connected to both sides of the beam. Main bridge lower chord 57. Its key technology is that steering wheel 11 is installed at the front end of main bridge 1, driving wheel 6 and rear supporting device 7 are installed in the rear end, and lifting mechanism is established on steering wheel and driving wheel. On the lower chord 57 of the main bridge between the steering wheel 11 and the rear support device 7, the moving track 58 is installed, and the concrete scraping device 8, the bottom arch formwork fixing device 9, the front support device 12 and the front support longitudinal are installed on the moving track 58. Move the supporting roller 10, and the traction mechanism 15 is installed on the main bridge lower chord 57 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com