Construction method of hydroelectric power station surge chamber vertical shaft under soft rock geological condition

A technology of geological conditions and construction methods, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve problems such as large shaft excavation diameters, difficulty in organizing construction, and affecting hydropower stations, so as to achieve obvious construction progress and improve uniformity , to ensure the effect of construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

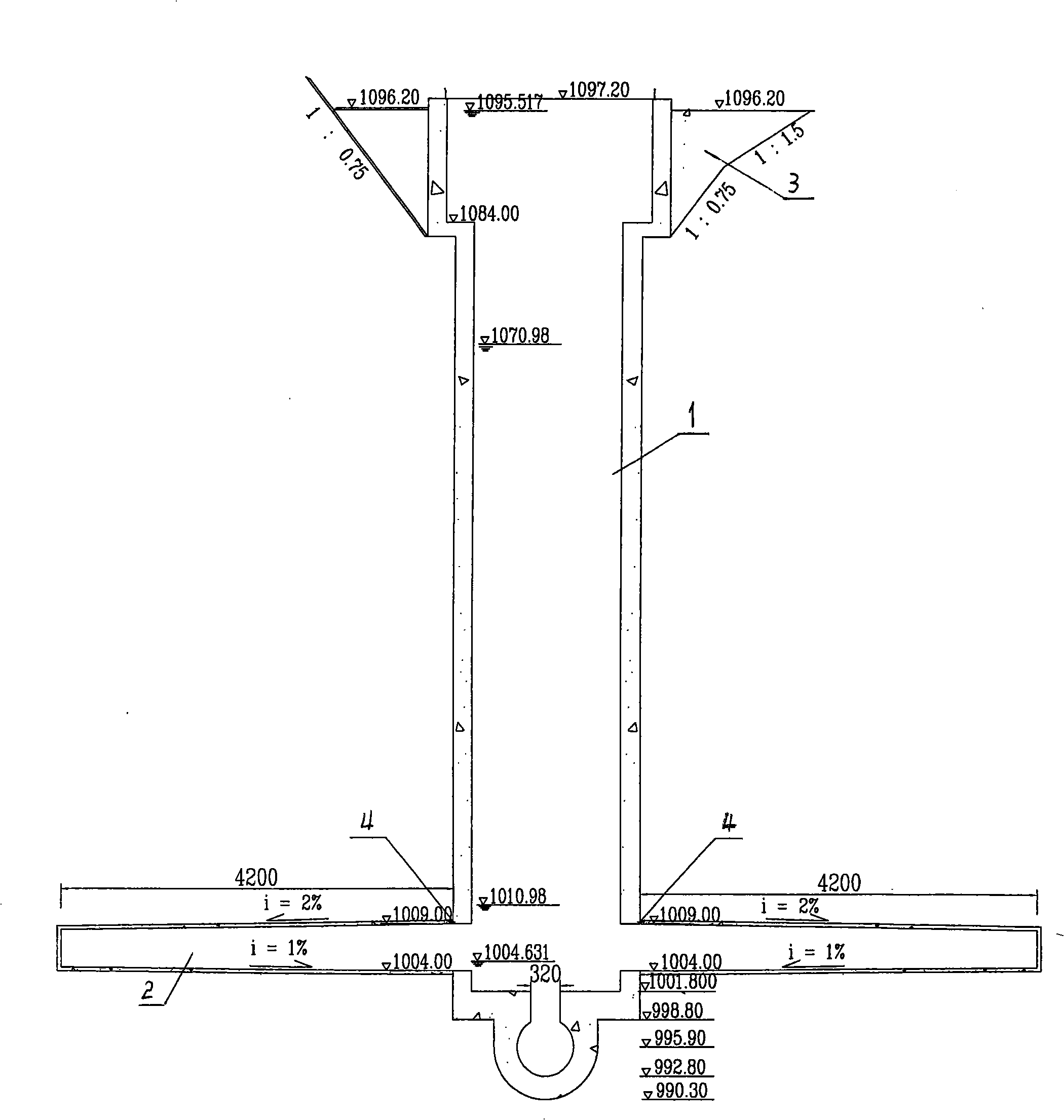

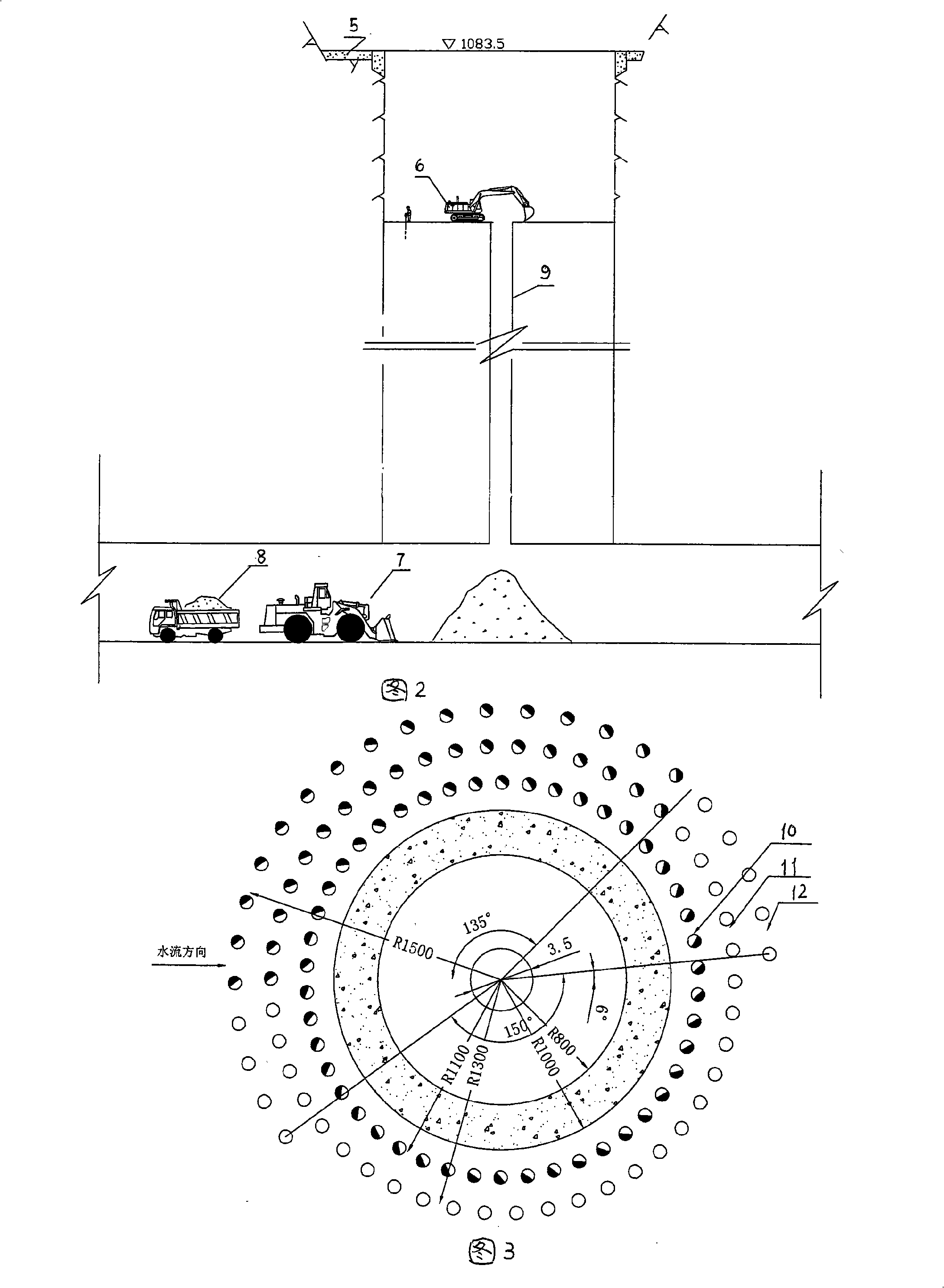

[0032] A construction method for a vertical shaft of a surge chamber of a hydropower station under weak rock geological conditions, mainly for shaft excavation, shaft support and lining construction, the diameter of the shaft excavation is ≥ 20m, and the depth of the shaft is ≥ 50m.

[0033] Safety advanced pre-hardening measures, which include:

[0034] 1) Add prestressed anchor cables at the side slope of the well;

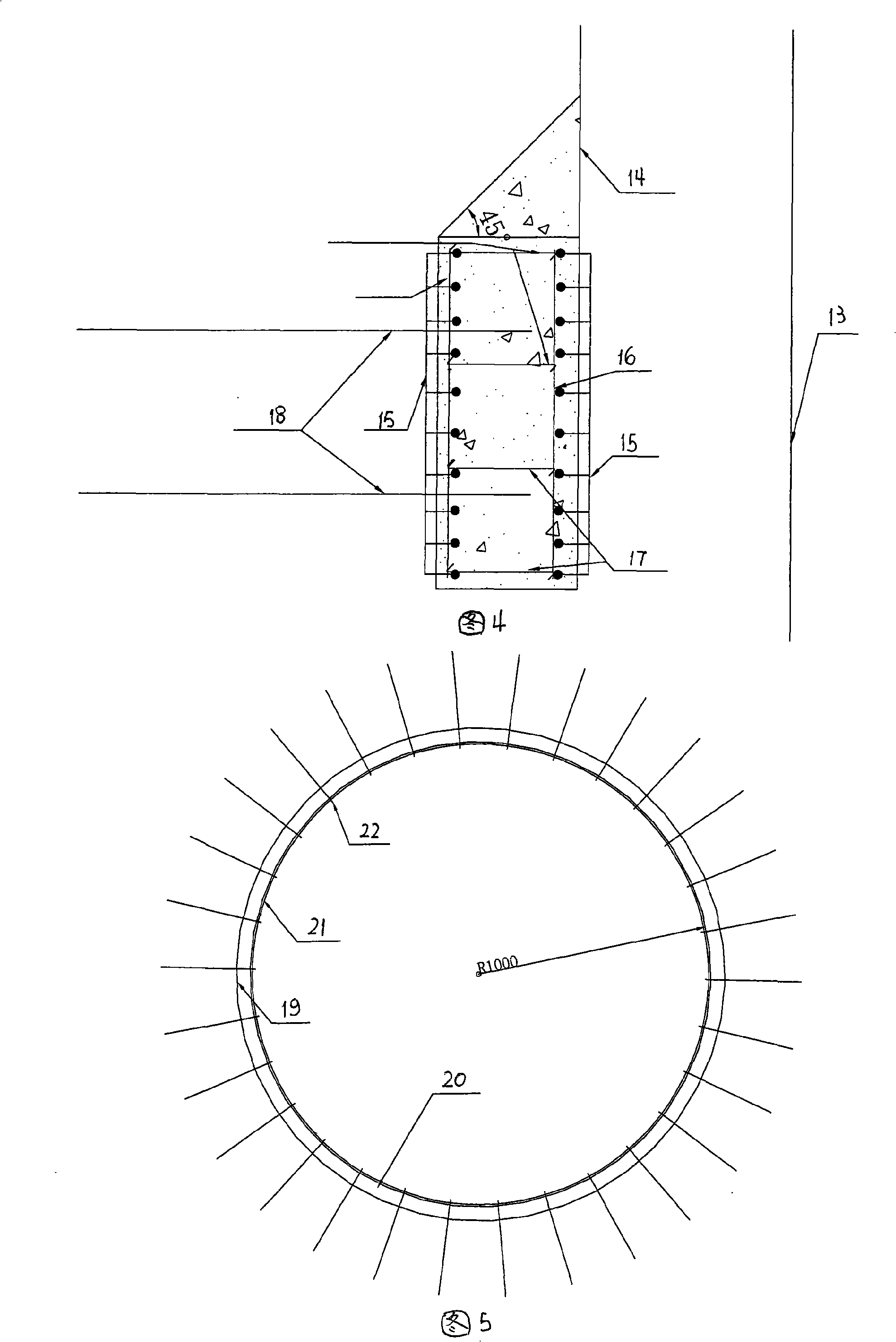

[0035] 2) Carry out deep hole consolidation grouting for the surrounding rock around the well: set 1 to 3 circles of grouting holes evenly around the well, the hole depth is slightly smaller than the depth of the shaft, and put multiple anchor tendons in the grouting holes;

[0036] 3) Pour reinforced concrete locks along the circumference of the well, and arrange multiple rows of radial grouting anchors along the circumference of the well wall. Set up a steel arch frame, on which a steel fiber concrete layer is sprayed;

[0037] The well section of the surge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com