Blasthole plug and method

A blast hole blocking and blast hole technology is applied in the field of blast hole clogging, which can solve the problems of poor drilling powder clogging effect, etc., and achieve the effect of solving the problem of poor blasting effect, saving materials and good blasting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

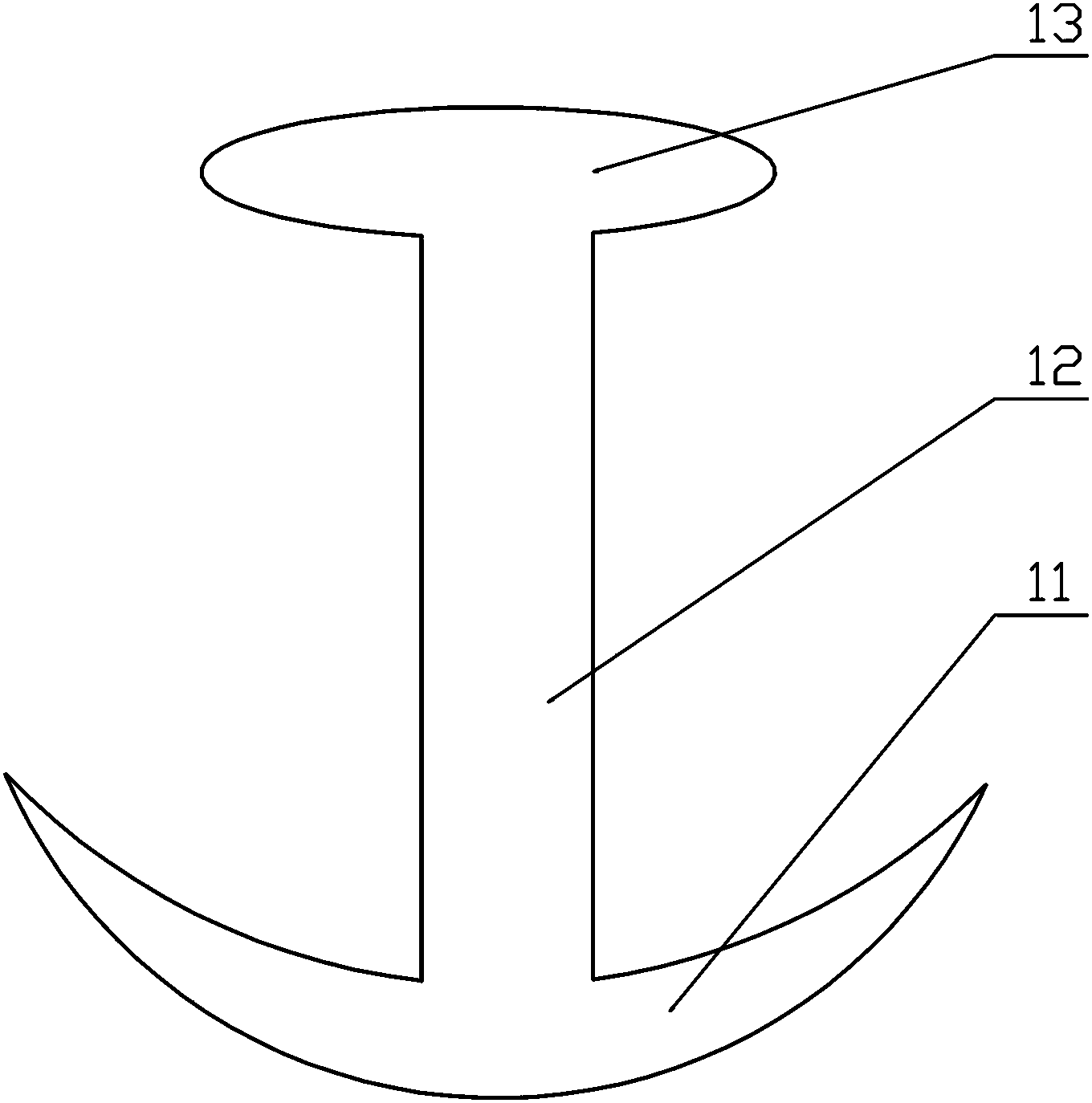

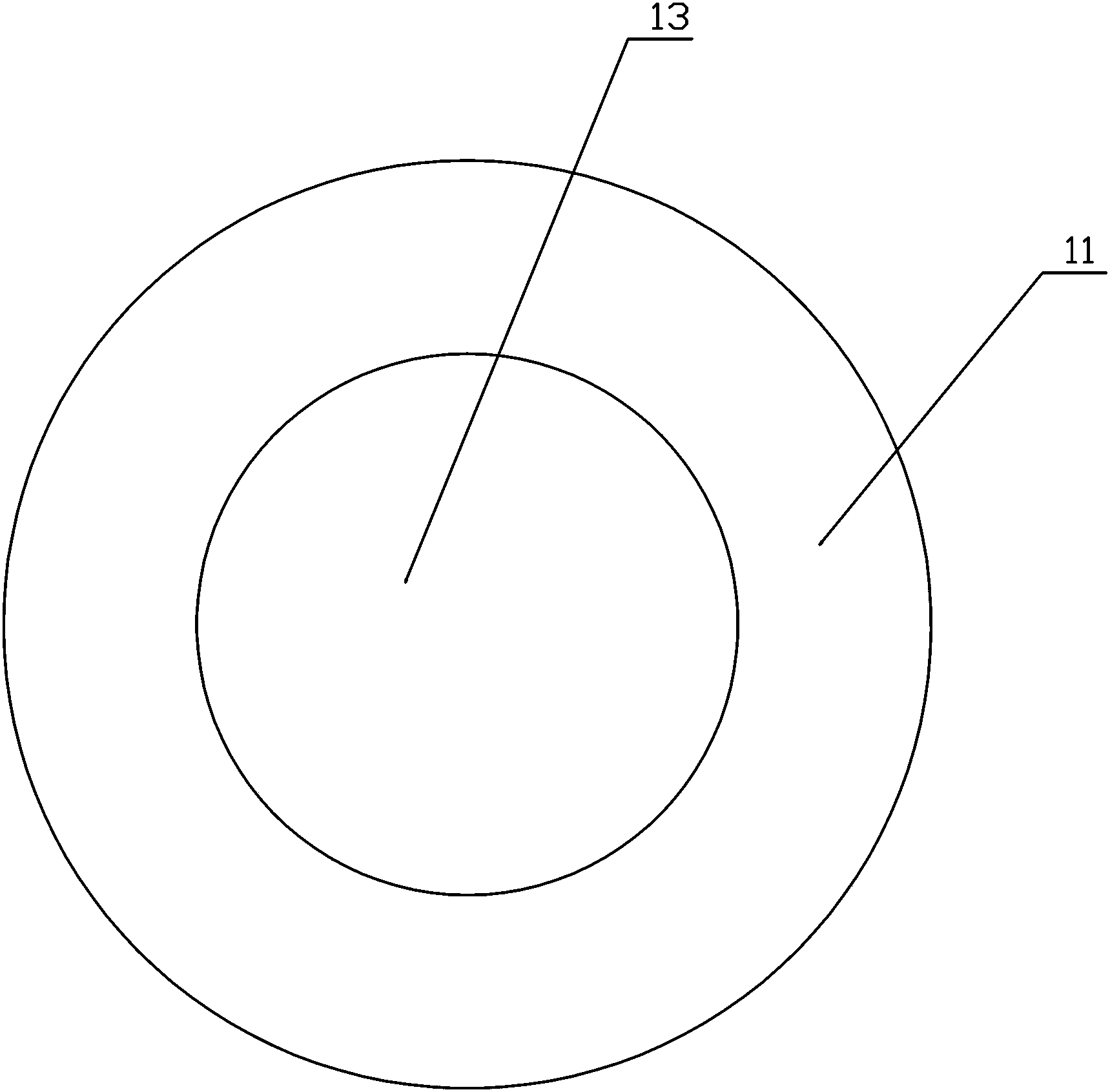

[0026] Such as figure 1 , 2 Among them, a blasthole plug, the front end of the plug 1 is provided with a concave arc-shaped portion 11, and the concave arc-shaped portion 11 gradually changes from thick to thin from the central axis portion to the edge portion, and the longitudinal section of the concave arc-shaped portion 11 is inward. Concave arc, the diameter of the inner concave arc portion 11 is greater than the diameter of the blasthole 2, the diameter of the rest of the plugging 1 is smaller than the diameter of the blasthole 2, and the height of the plugging 1 is greater than the diameter of the blasthole 2, so as to prevent the plugging 1 from Flip inside hole 2. With this structure, when the plug 1 is placed in the blasthole 2, the structure of the concave arc portion 11 enables the plug 1 to move in one direction only in the blasthole 2, thereby improving the plugging effect, and can form a Sealing to prevent substances in the plugging section, such as drilling po...

Embodiment 2

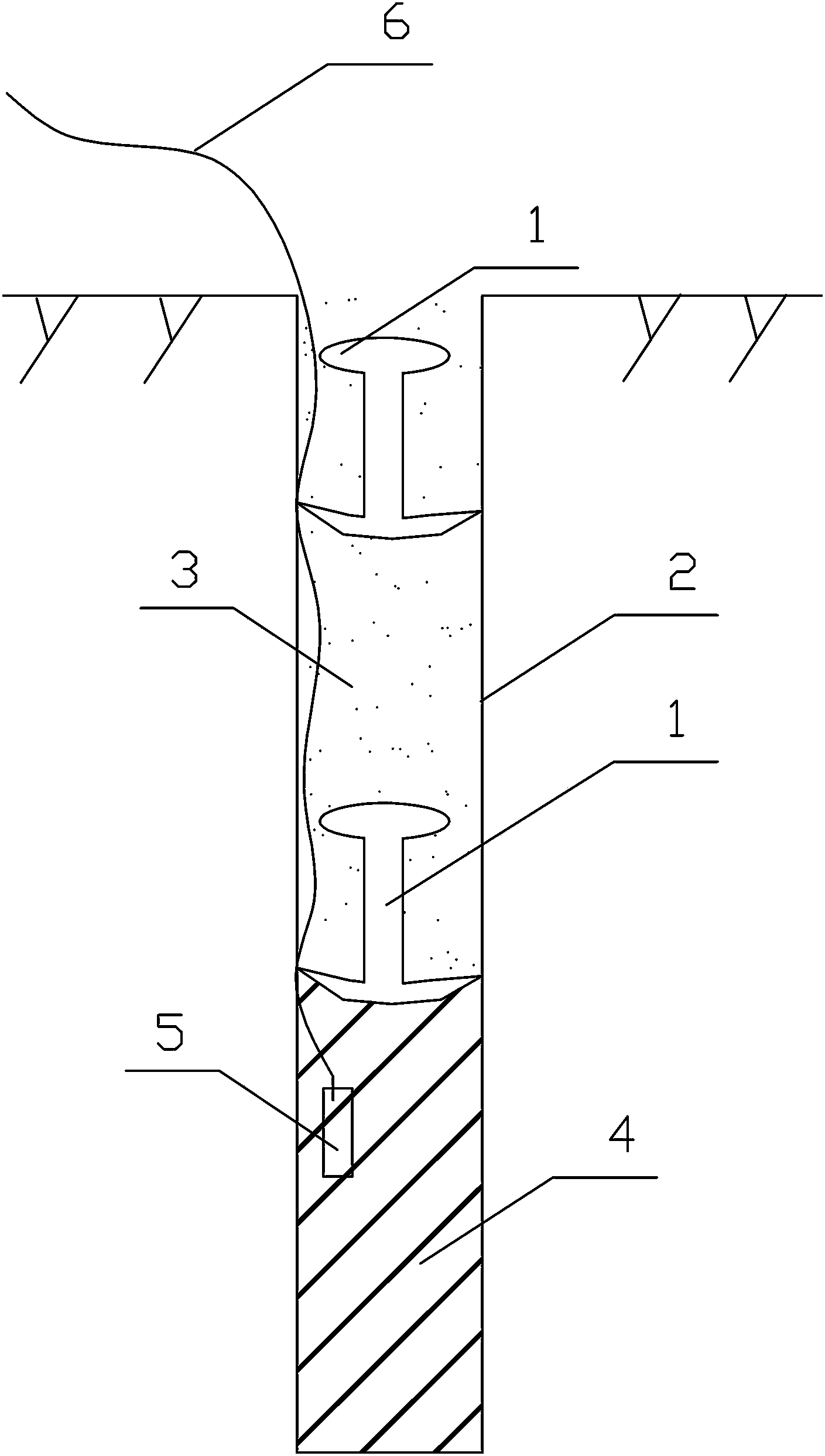

[0031] Such as Figure 4 Among them, a method for drilling and blasting using the above-mentioned blasthole plugging, comprising the following steps:

[0032] 1. Drilling to form the blast hole 2 and then charging;

[0033] 2. Load the detonator 5 and draw the detonator lead wire 6;

[0034] 3. Put the concave arc portion 11 of the plug 1 downward into the blast hole 2, and insert it with a gun stick until the device is in close contact with the explosive;

[0035] 4. Fill in the drill powder 3 and compact it. When compacting, use gun sticks for compaction.

[0036] Realize adopting drilling powder to plug blast hole through above-mentioned steps. Since the diameter of the concave arc-shaped portion 11 of the plug 1 is slightly larger than that of the blast hole, and because of its special shape, it can only move in one direction toward the bottom of the hole, so it can effectively prevent the drill powder from entering the charge section. In addition, due to its one-way m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com