Large dead zone residual ore recovery method

A recovery method and empty area technology, applied in ground mining, earth square drilling, underground mining, etc., can solve problems such as poor construction safety conditions, high mining costs, and low recovery rate, so as to improve safety conditions and improve residual ore recovery The effect of reducing ore falling and supporting costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

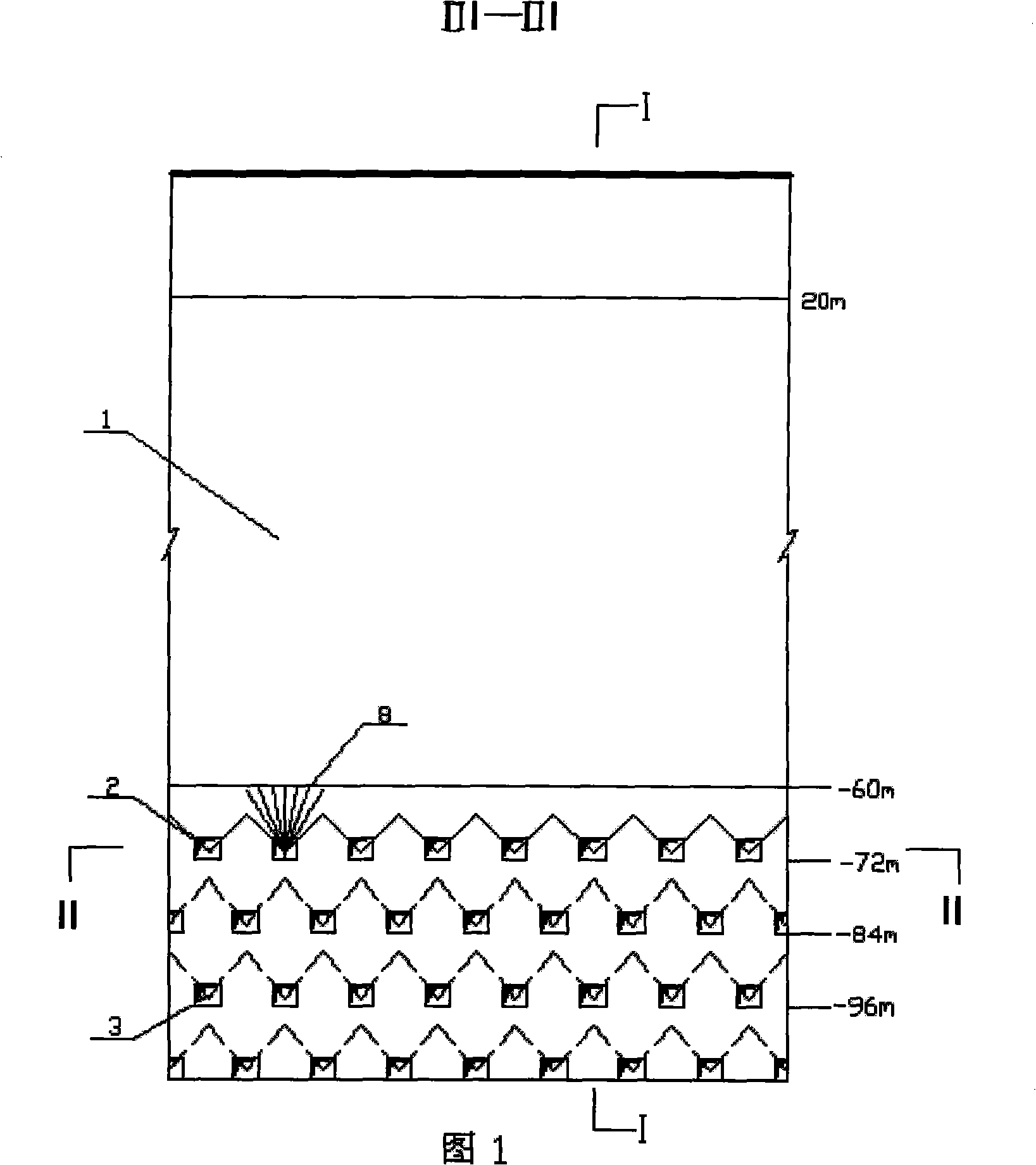

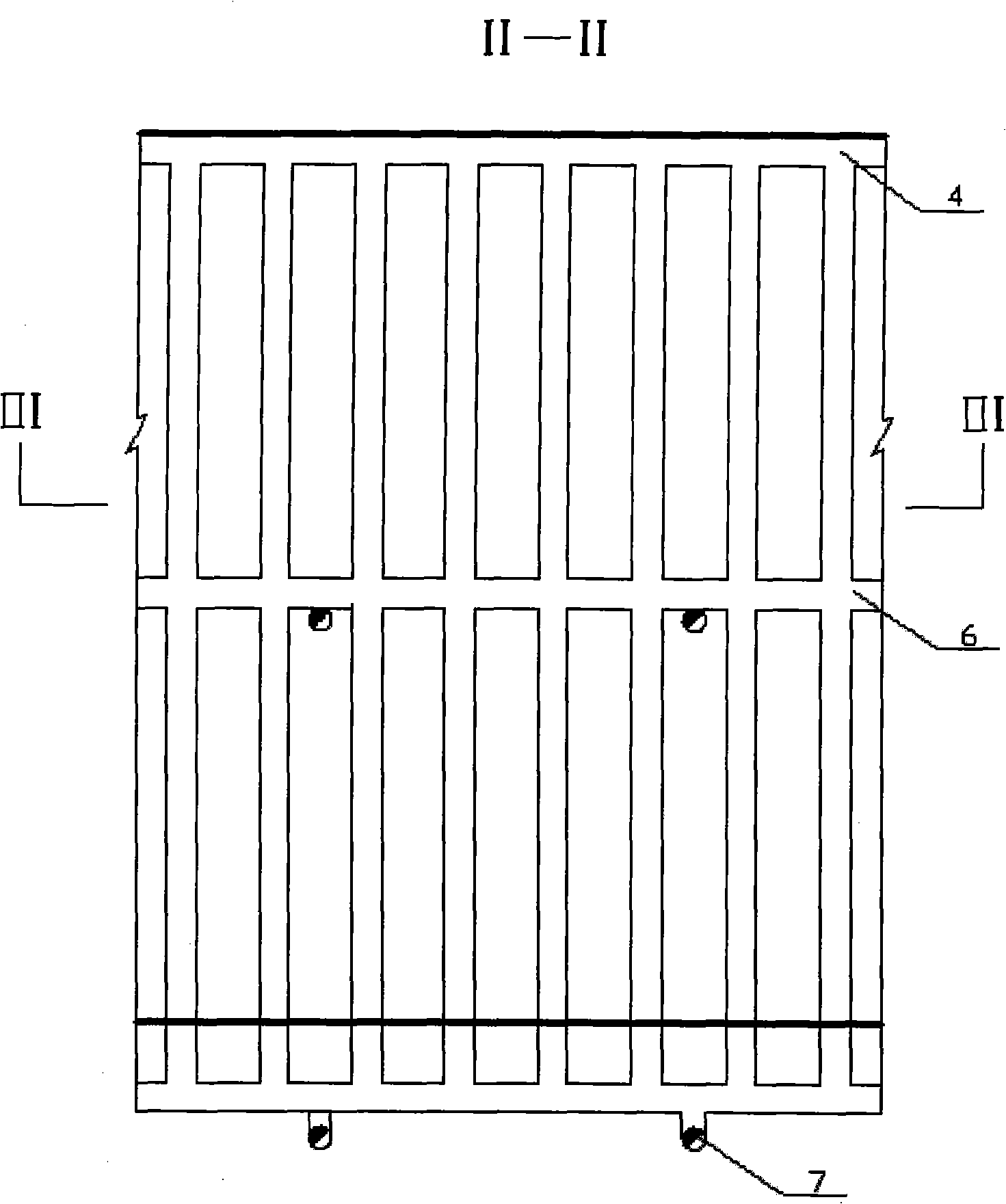

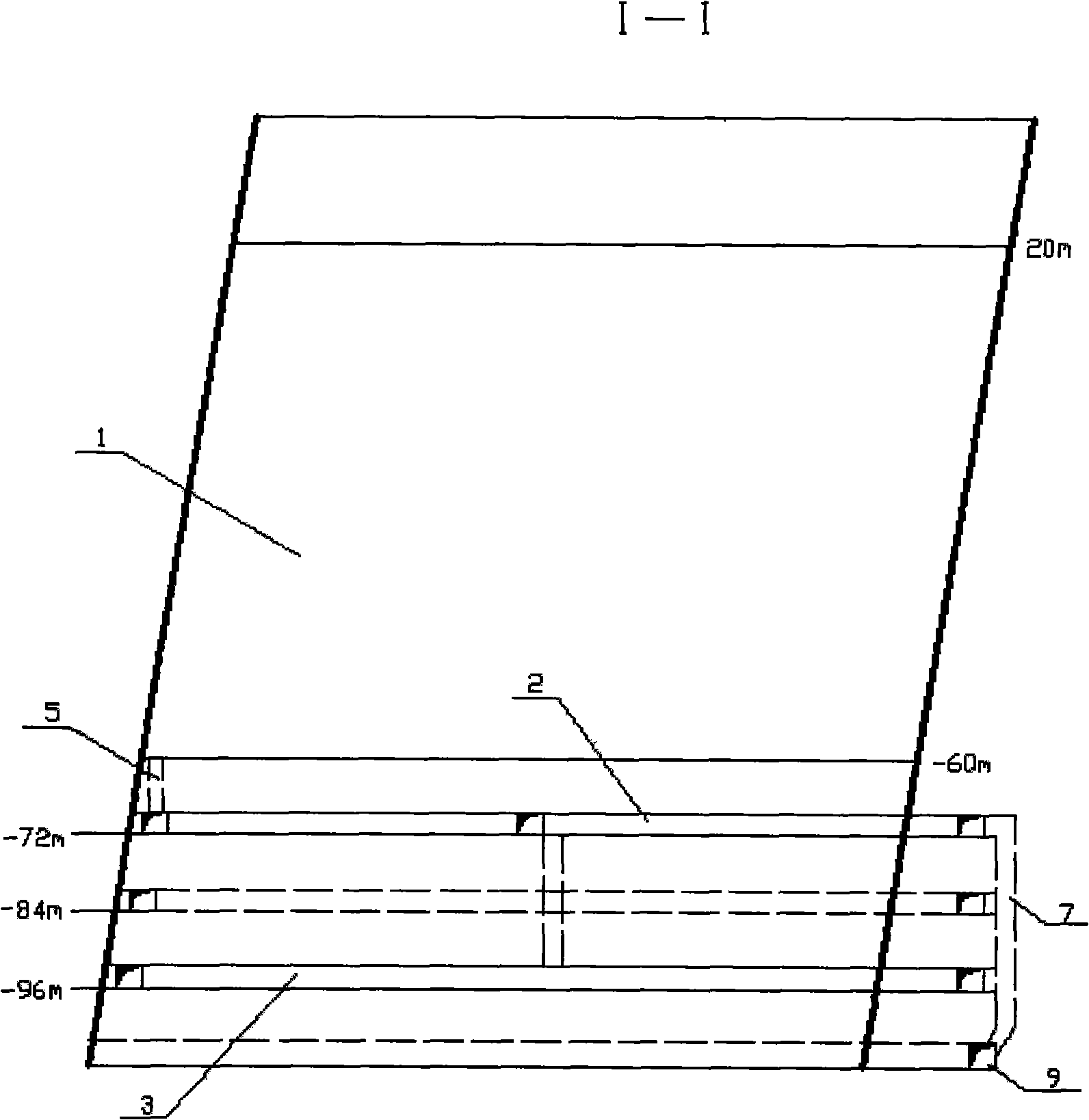

[0012] Figure 1~ image 3 An ore body in Zhongyang has an average horizontal thickness of 120 meters. The upper part is affected by civilian mining and forms a very irregular honeycomb goaf. There are a large number of residual ore pillars in the goaf, and the height of the goaf is +20-60 meters.

[0013] Adopt forced caving and induced caving, and set up a recovery route to recover the residual ore 1 in the upper empty area, and the height of the section is 12 meters.

[0014] In Figure 1 and image 3 The lower part of the honeycomb-shaped goaf 1-72 meters horizontal excavation of the mining roadway 2, the distance between the mining roadways is 12.5 meters, and the drilling and mining operations are carried out in the mining roadway. The medium-deep hole falling method is adopted to form a large continuous space after blasting the bottom of the empty area and adjacent to the ore body, which induces the caving of the residual ore 1 in and around the upper empty area. The caving res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com