United method for tunneling super-strong or strong rock burst hole section of TBM construction tunnel

A tunnel and rockburst technology, which is applied in the field of tunnel excavation and support, can solve the problems of being unable to deal with extremely strong or strong rockburst limitations, achieve strong economic and social benefits, ensure tunneling speed, and ensure safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The diameter of the designed excavation section of the TBM construction tunnel in this embodiment is 10m, and the diameter of the design excavation section of the TBM construction tunnel is greater than 10m, which is to comprehensively consider the size of the excavation section of the upper pilot tunnel and the size of the construction machinery in the drilling and blasting excavation. Factors, for TBM construction tunnels with diameters less than 10m, only the full-face drilling and blasting method can be selected to deal with extremely strong or strong rockbursts.

[0023] Its joint tunneling method includes the following steps:

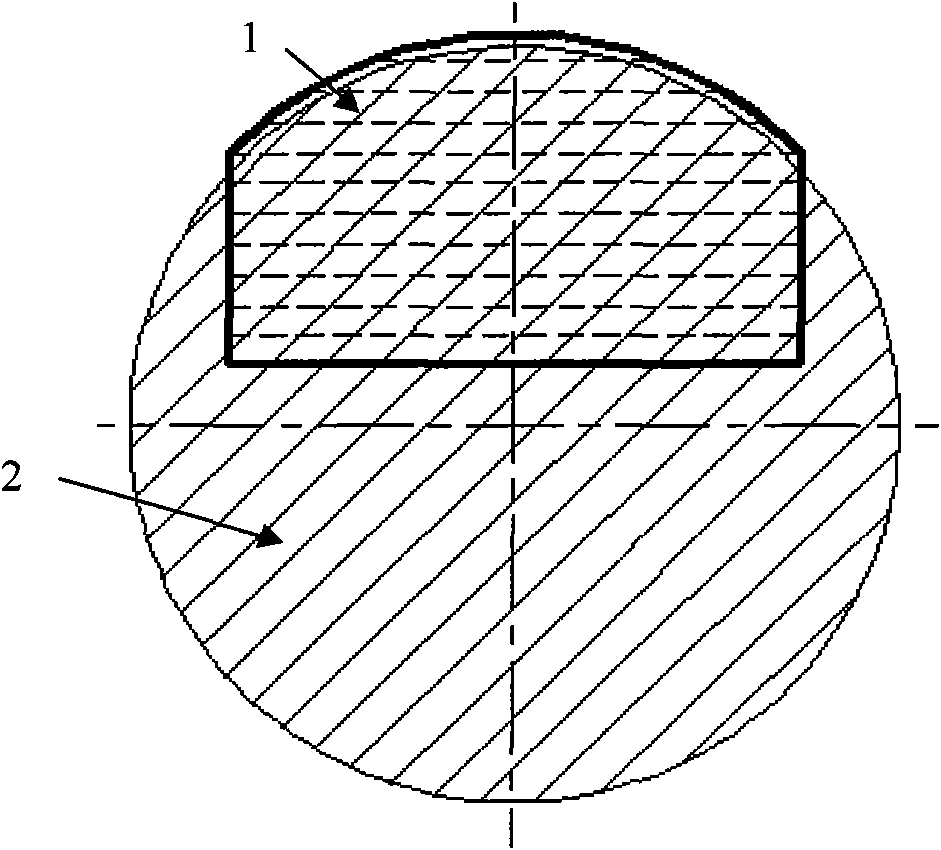

[0024] ①The design of the tunnel excavation section for TBM construction. The excavation section is divided into two parts, the upper part is the upper pilot tunnel, and the lower part is the TBM excavation section. The relative positional relationship between the two is as follows: figure 1 shown.

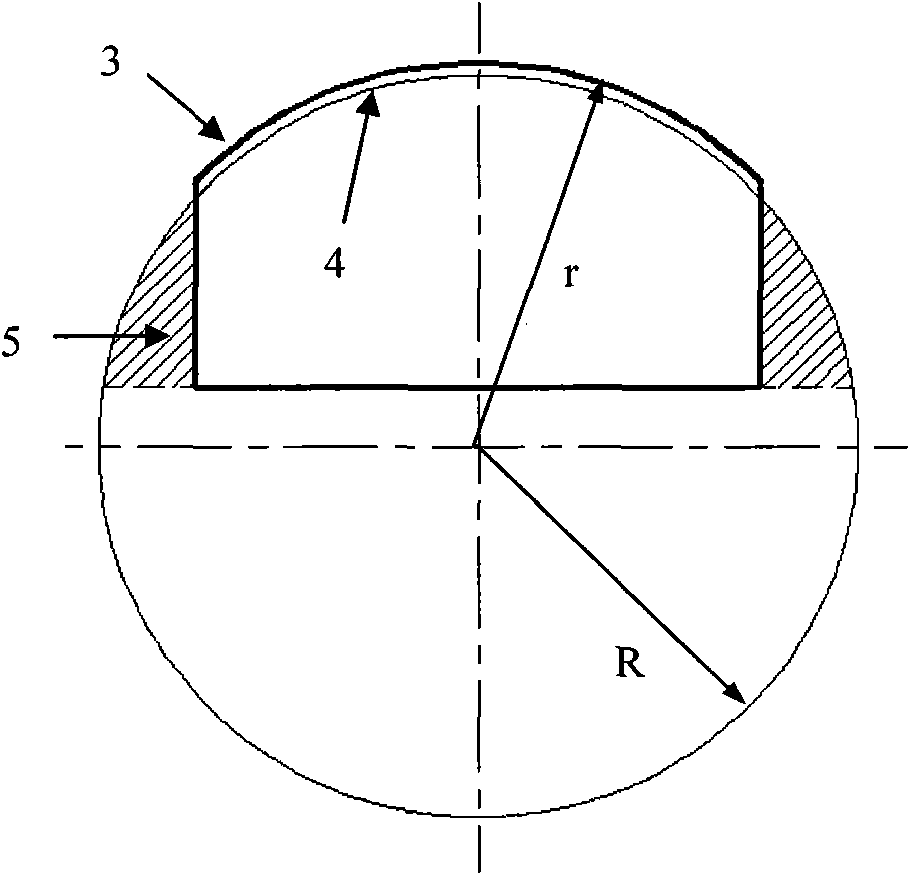

[0025] ②The design of the excavation se...

Embodiment 2

[0029] The diameter of the designed excavation section of the TBM construction tunnel in this embodiment is 10m, and the diameter of the design excavation section of the TBM construction tunnel is greater than 10m, which is to comprehensively consider the size of the excavation section of the upper pilot tunnel and the size of the construction machinery in the drilling and blasting excavation. Factors, for TBM construction tunnels with diameters less than 10m, only the full-face drilling and blasting method can be selected to deal with extremely strong or strong rockbursts.

[0030] Its joint tunneling method includes the following steps:

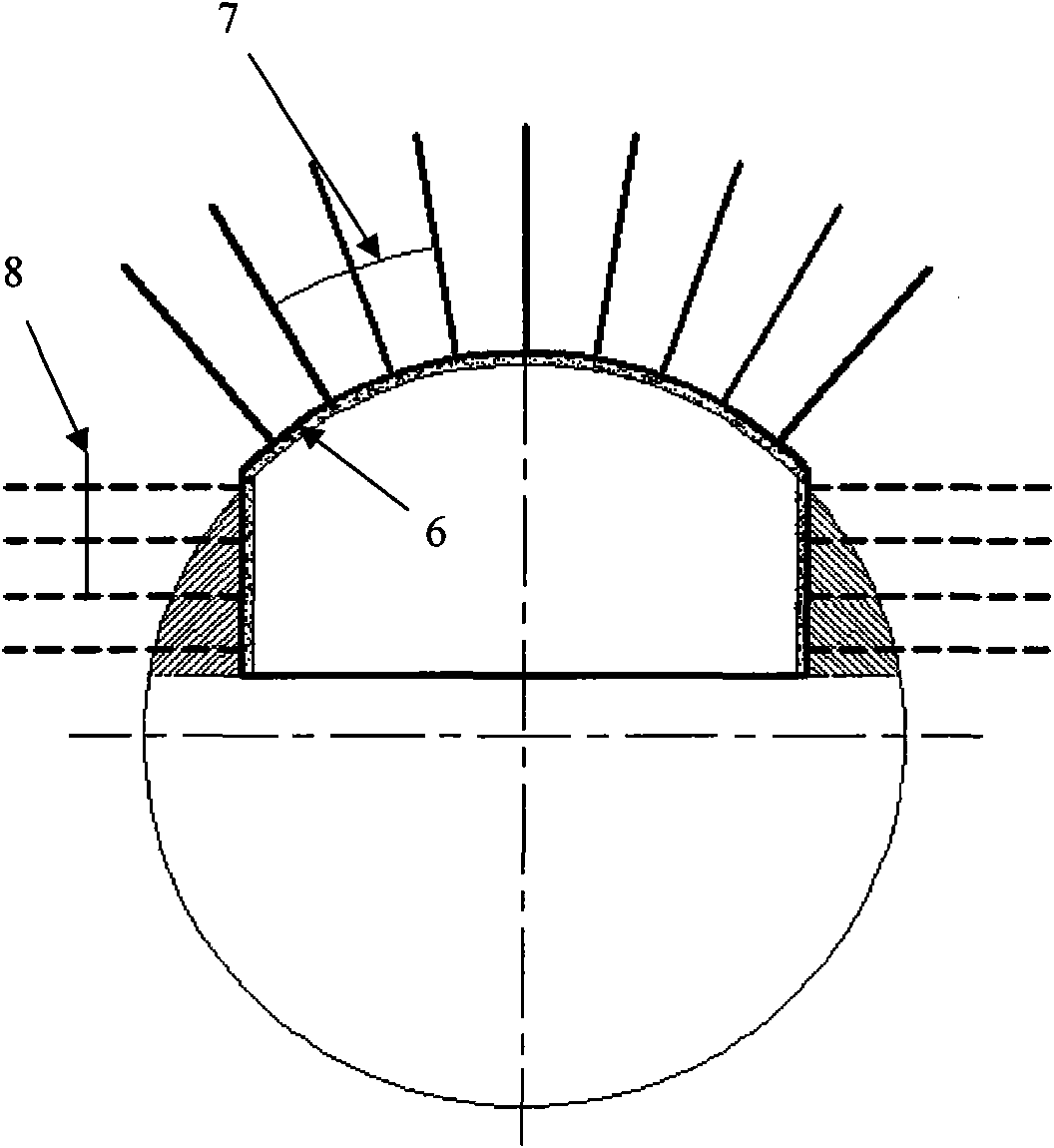

[0031]①The design of the tunnel excavation section for TBM construction. The excavation section is divided into two parts, the upper part is the upper pilot tunnel, and the lower part is the TBM excavation section. The relative positional relationship between the two is as follows: Figure 5 shown.

[0032] ②The design of the excavation se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Layer thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com