Drawing in machine

A drawing-in machine and threading technology, applied in the field of drawing-in machines, can solve problems such as difficult to find heald faults, complicated work to eliminate faults, complicated procedures and heald transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

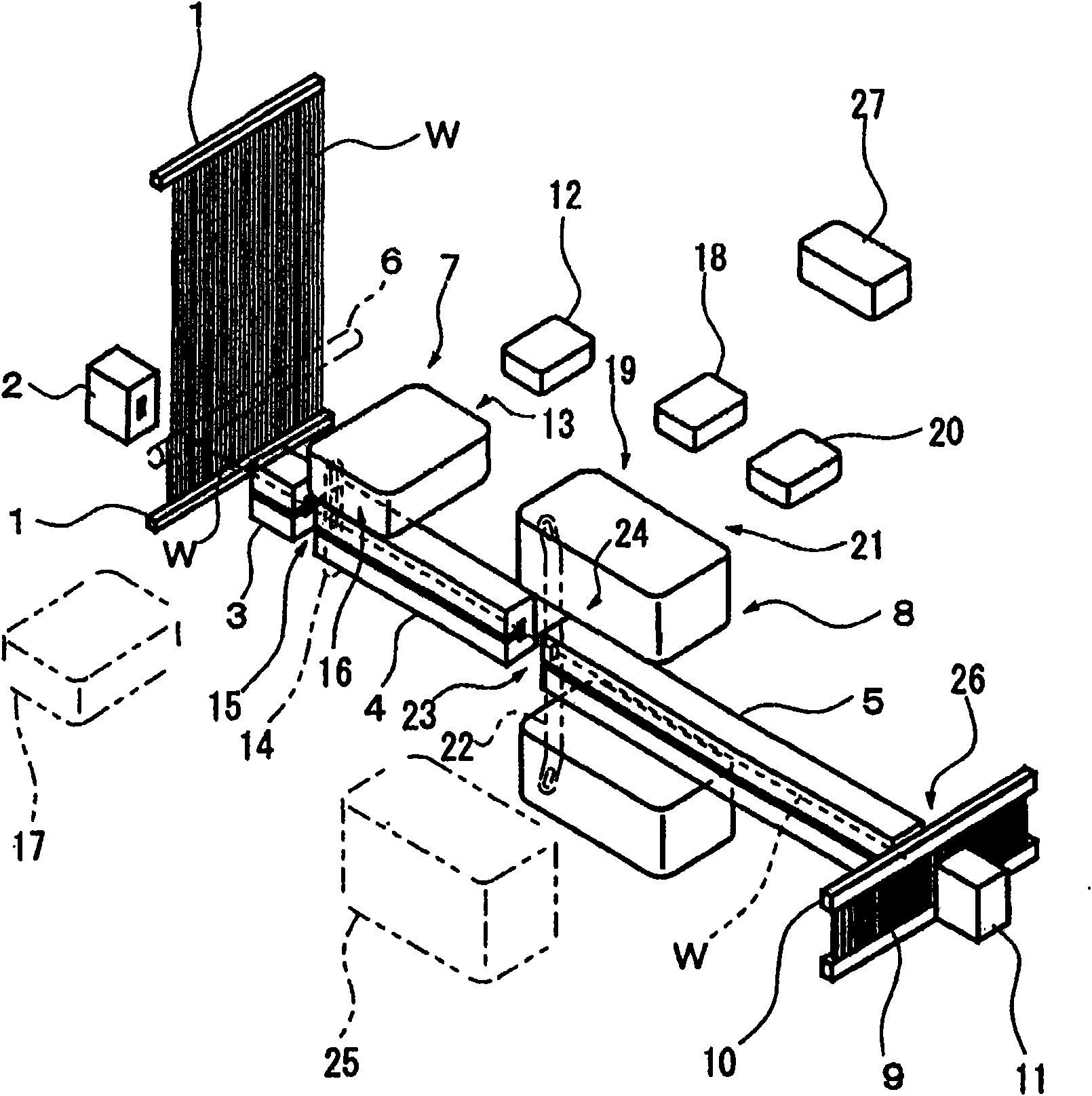

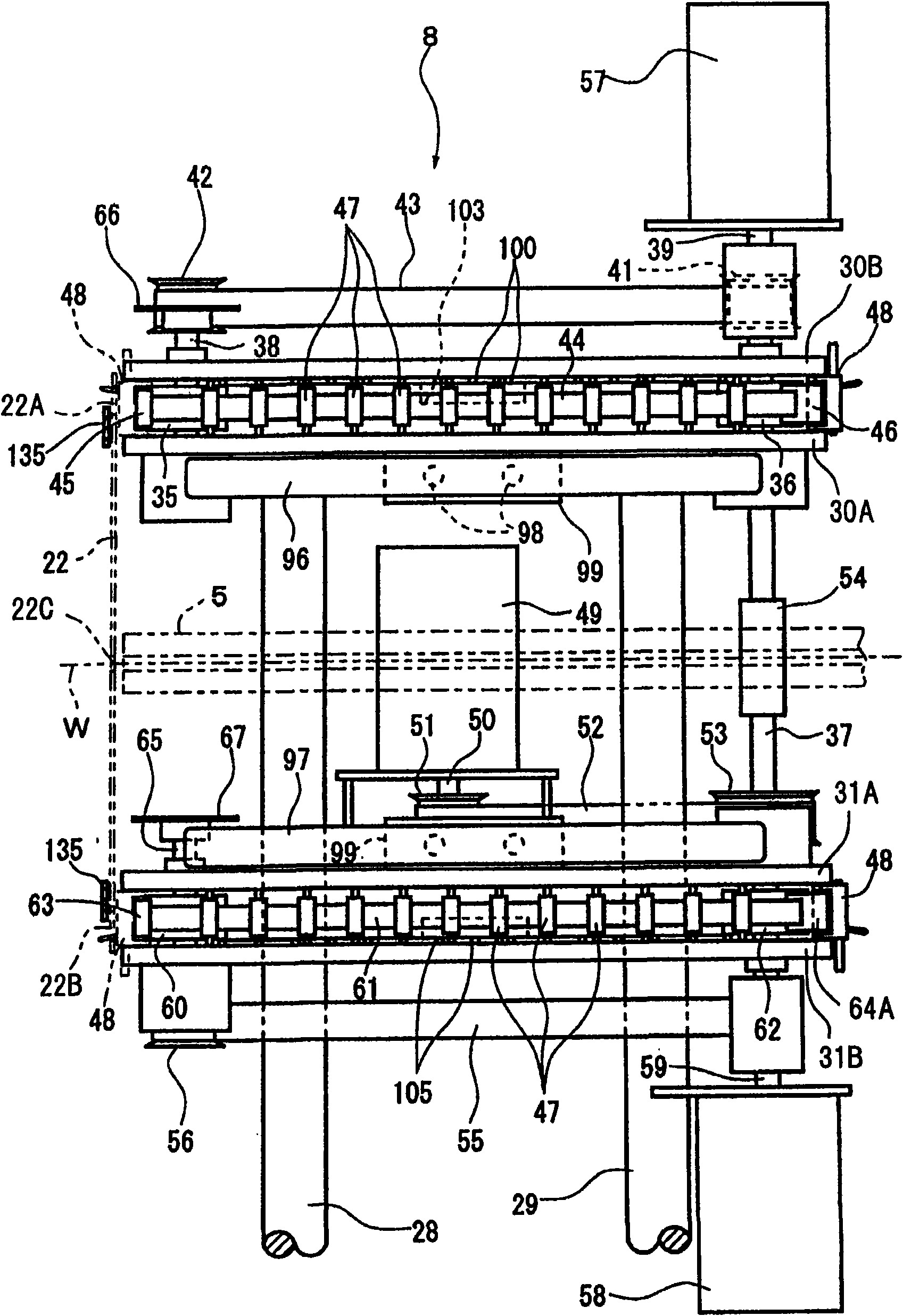

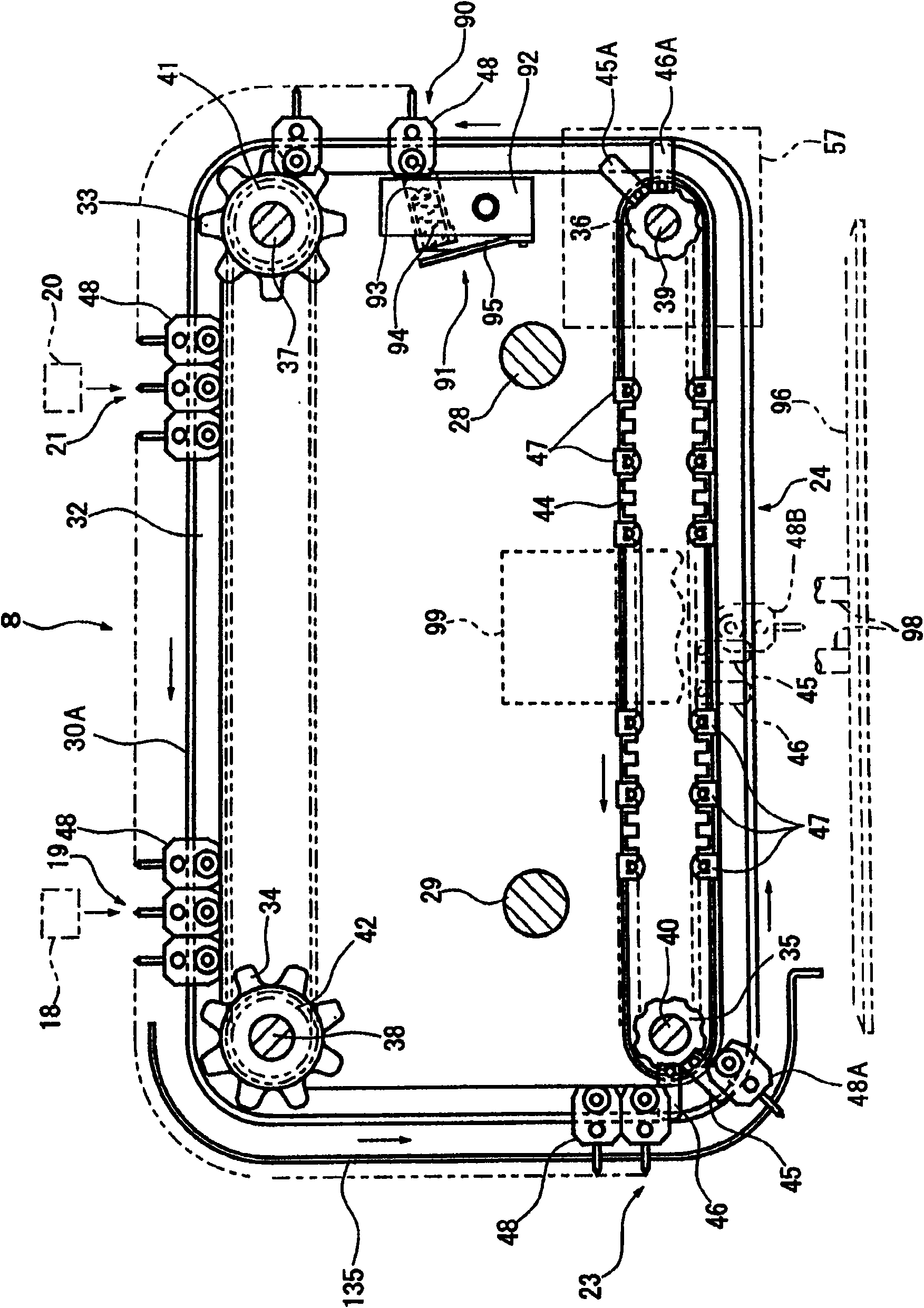

[0028] The following will refer to the attached Figures 1 to 8 A first preferred embodiment of the present invention will be described. First, refer to the attached figure 1 A drawing-in machine according to a first preferred embodiment of the present invention will be described. The nozzles 2 and the guide members 3, 4, 5 are arranged in a straight line on both sides of a plurality of warp yarns W drawn from a warp beam (not shown) and clamped in the clamping frame 1 . A guide rod 6 is provided between the nozzle 2 and the warp yarn W. As shown in FIG. The dropper conveying mechanism 7 is provided on the upper portion of the flow guide member 4 . The heald conveying mechanism 8 has a pair of conveying members provided on the upper and lower sides of the flow guide member 5, respectively. A reed 10 having a plurality of reed teeth 9 spaced apart from each other at a small pitch is arranged perpendicularly to the ends of the flow guide members 5 . A reed spacer 11 with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com