Method for optimizing a textile production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

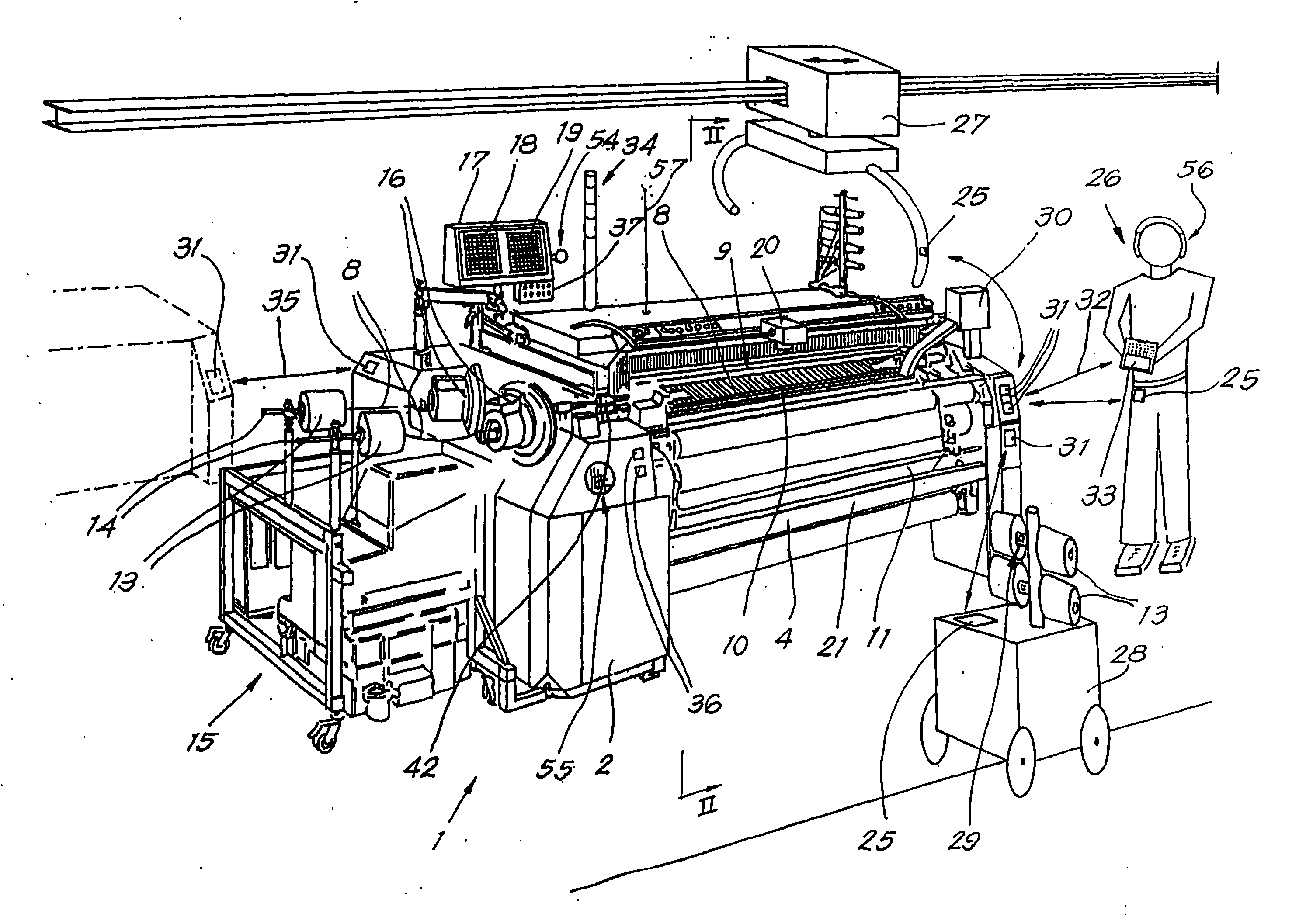

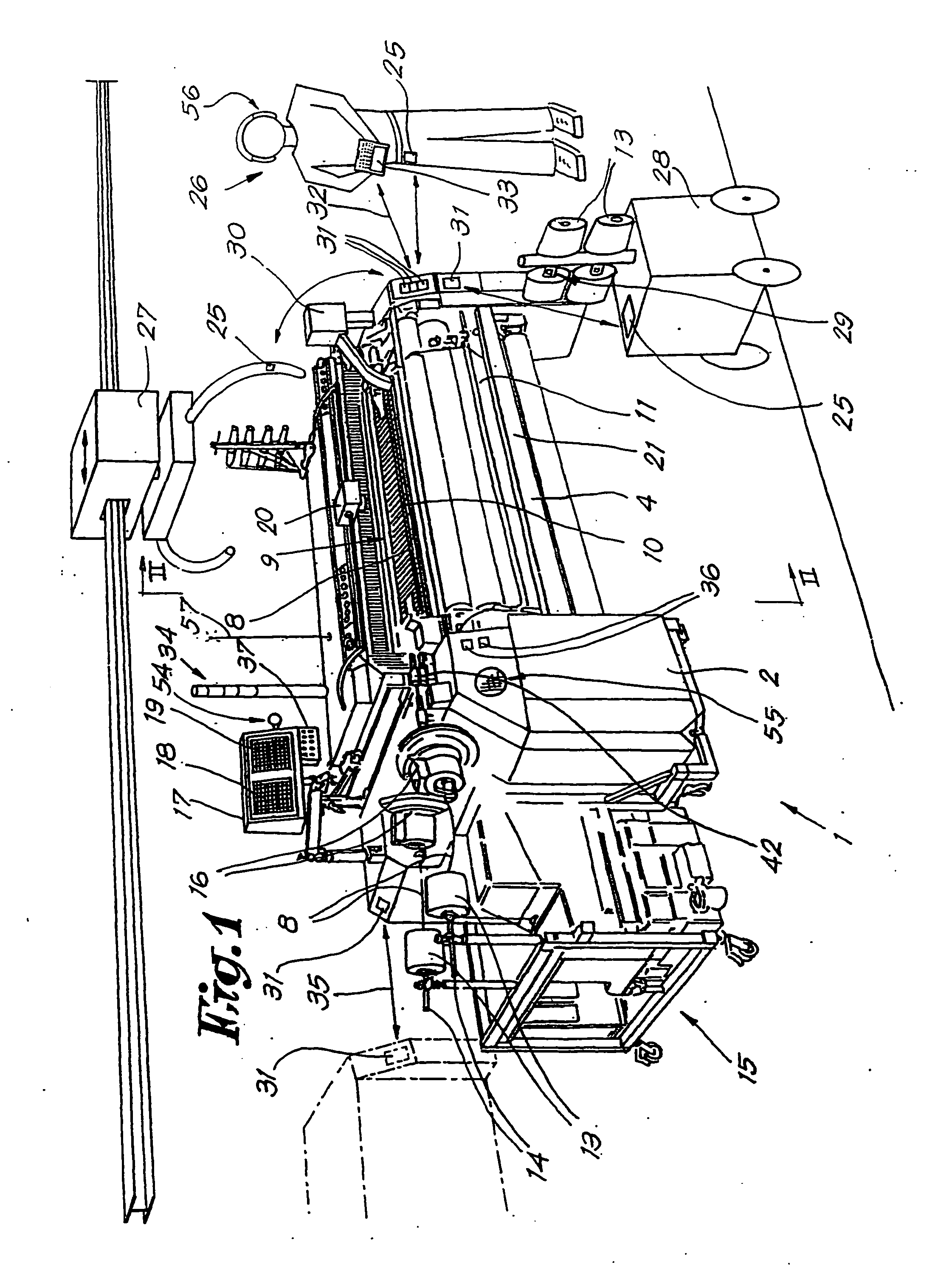

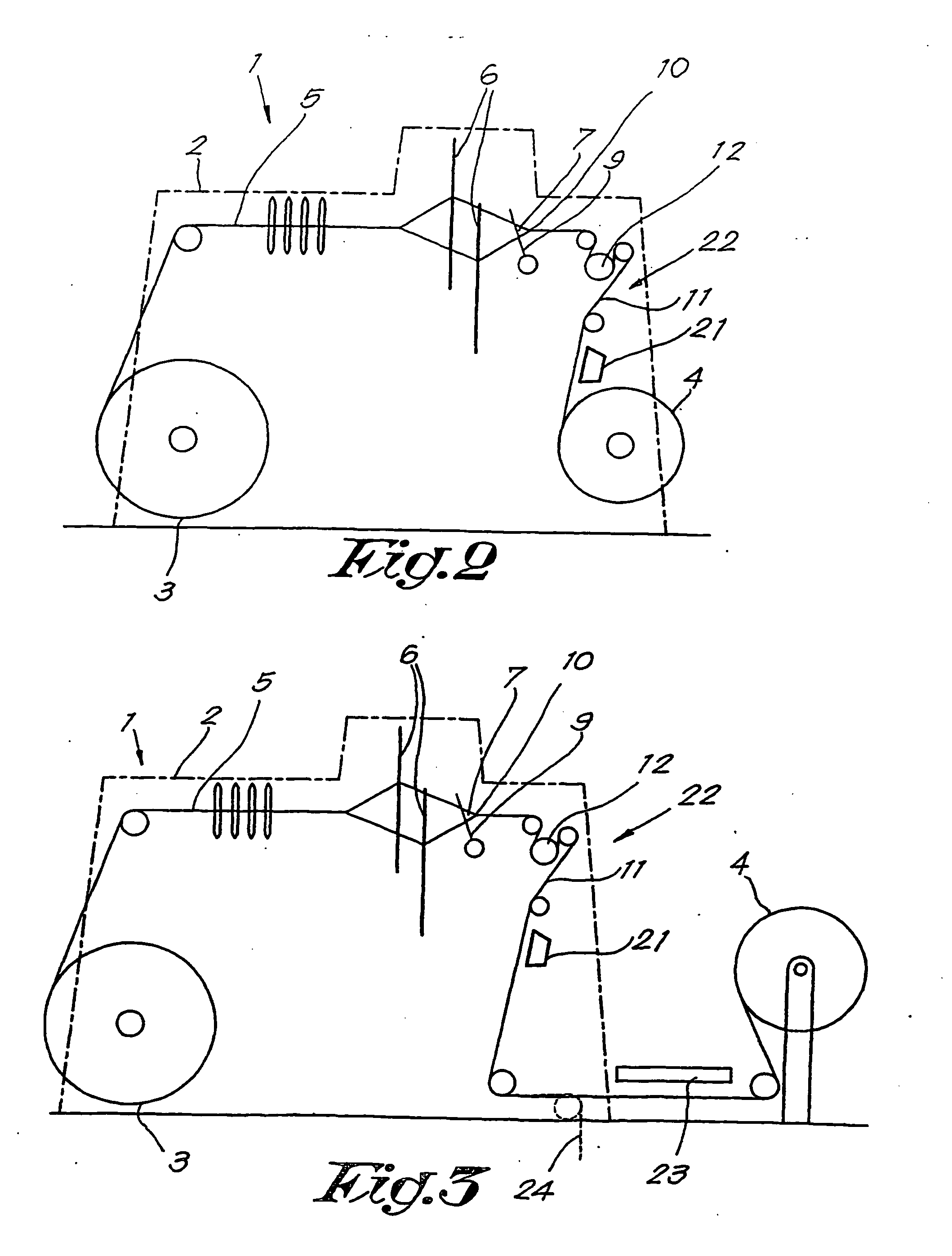

[0189] In FIGS. 1 and 2, a weaving machine 1 is represented which, as known, includes a chassis 2 in which a warp beam 3 and a cloth roll 4 can be provided. In a known manner, thereby warp threads 5 are wound off the warp beam 3 and fed through weaving frames 6, such that a shed 7 is formed, in which weft threads 8 can be beaten, by means of the reed 9, against the beating line 10 of the already formed cloth or fabric 11. The formed cloth 11 is transported off by means of a number of rolls, amongst which the so-called sand roll 12, in order to be wound onto the cloth roll 4.

[0190] The weft threads 8 are supplied in a known manner from bobbins 13, which are mounted on pins 14 of a bobbin rack 15, by the intermediary of prewinders 16.

[0191] The weaving machine 1 is provided with a machine terminal 17.

[0192] According to said first aspect of the invention, as explained in the aforegoing, different visualizations are realized on the machine terminal 17, which comprises, amongst other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com