High-speed heavy-duty Jacquard shedding device

A jacquard opening, heavy-load technology, applied in jacquard machines, textiles, textiles and papermaking, etc., can solve the problems of long transmission line, large deformation of lifting knife, high power consumption, etc., and achieve less weaving defects, small deformation of lifting knife, small load effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

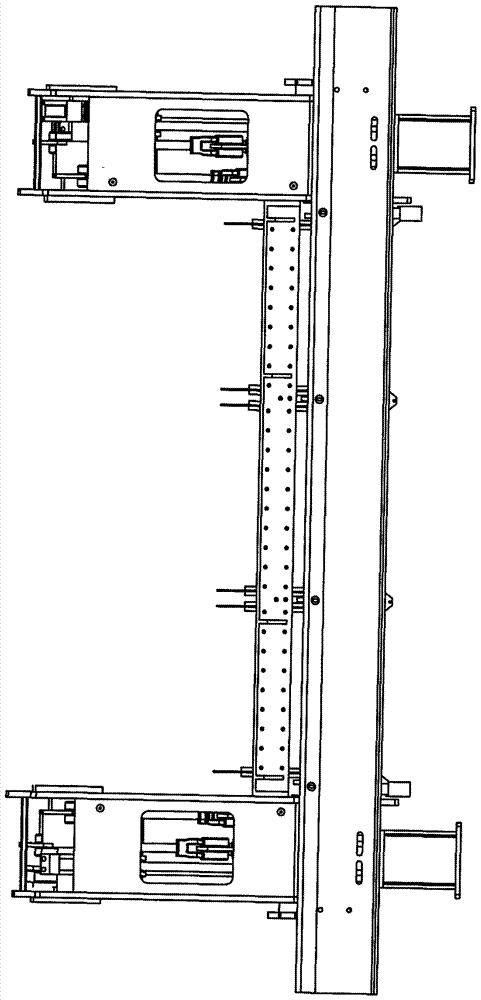

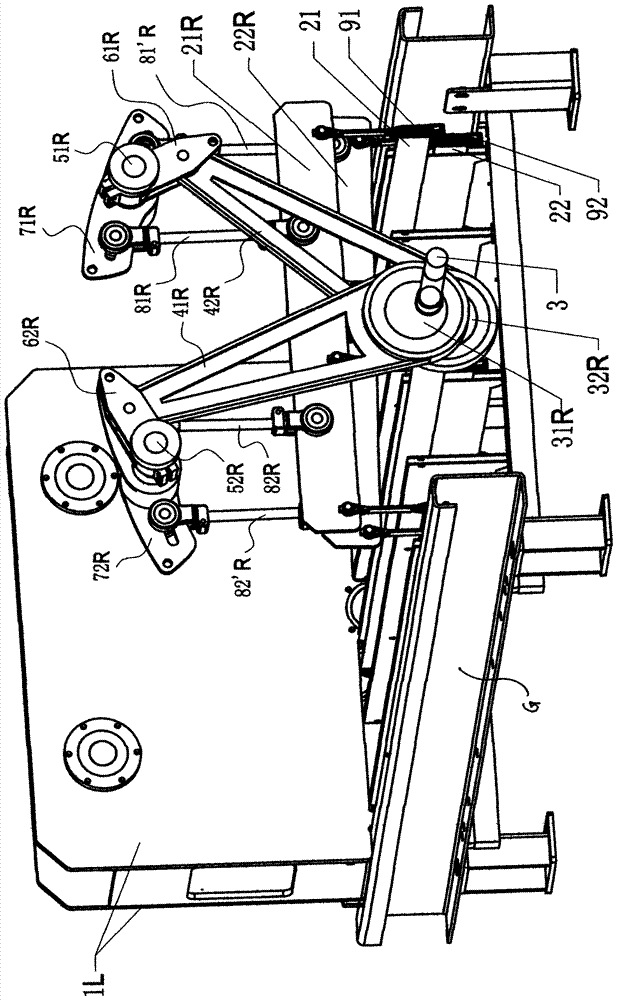

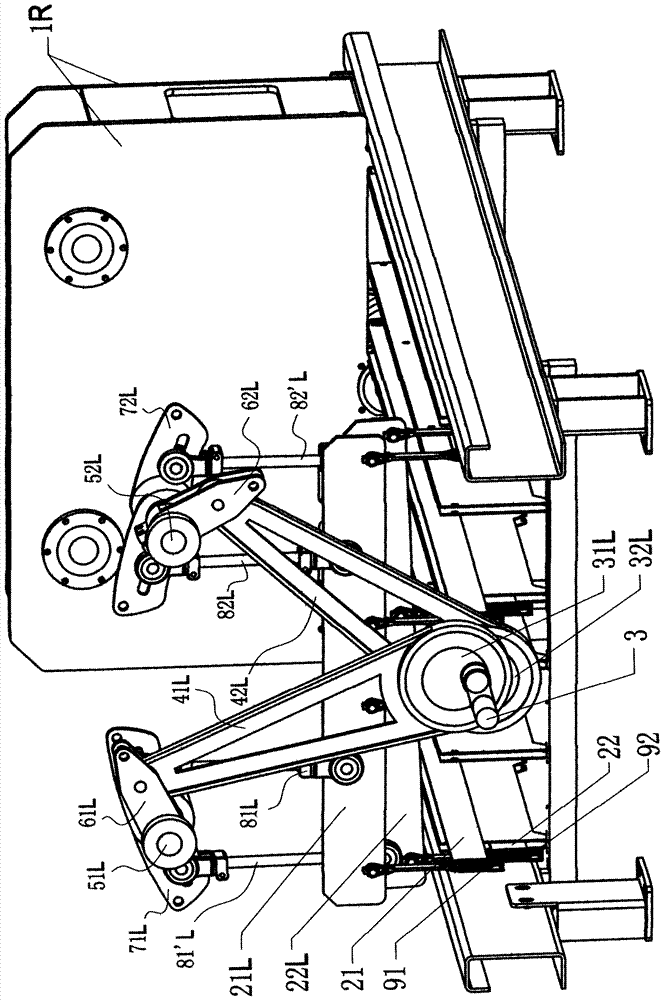

[0024] see figure 1 , 2 , Shown in 3 and 4 are preferred embodiments of the present invention.

[0025] High-speed heavy-duty jacquard shedding device, wherein, the long lifting knife group 21 and the short lifting knife group 22 arranged in the longitudinal direction are respectively driven by a pair of outer lifting knife holders 21L, 21R and a pair of inner lifting knife holders 22L, 22R arranged in the longitudinal direction. Carry out the reciprocating motion of alternate rising and falling, which is realized by the motion conversion between the eccentric shaft 3 and the swing mechanism, and the eccentric shaft 3 located at the bottom of the two side wall panels 1L, 1R is equipped with a motion transmission to the swing mechanism There are four sets of eccentric wheel linkage mechanisms, and the movement is synchronously equipped on both sides of the eccentric wheel shaft 3. The two sets of eccentric wheel linkage mechanisms arranged adjacently include internal eccentric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com