Method for producing fuel and road asphalt modifier by utilizing waste and old textiles

A technology of waste textiles and road asphalt, which is applied in the direction of fuel, liquid carbon-containing fuel, solid waste removal, etc., can solve the problems of air pollution, high technical requirements, high investment costs, etc., to reduce dependence on oil, reduce environmental pollution, The effect of mitigating environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

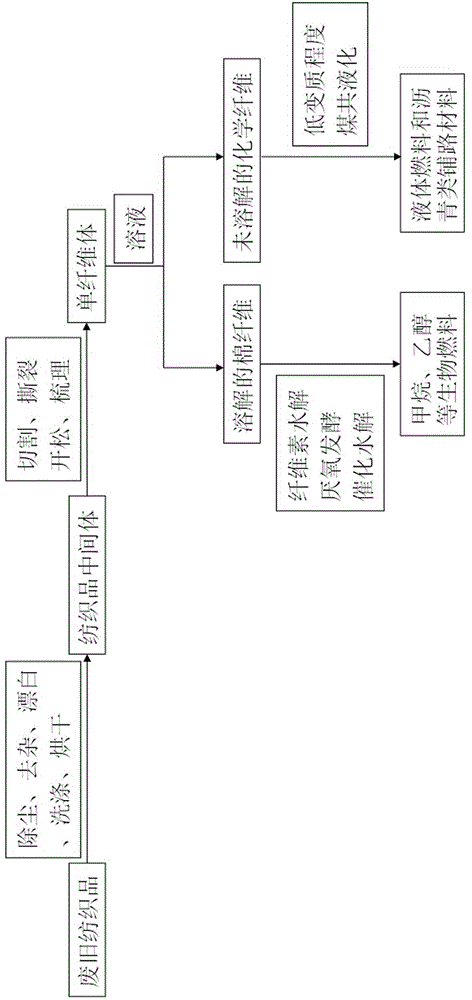

[0021] Such as figure 1 As shown, the method of using waste textiles to produce fuel and road asphalt modifier in this embodiment includes the following steps: (1) Pretreatment of waste textiles: first, the waste textiles are subjected to dedusting, impurity removal, bleaching, washing and drying in sequence. Dry processing, then cutting, tearing, opening and carding to obtain monofilaments; (2) dissolving the monofilaments obtained in step (1) with a sodium hydroxide / urea aqueous solution with a temperature of 285K and a mass concentration of 20% body, wherein the sodium hydroxide / urea aqueous solution is a mixed aqueous solution of 5wt% sodium hydroxide / 15wt% urea, and after solid-liquid separation, cotton cellulose solution and undissolved chemical fibers are obtained; (3) to cotton cellulose solution Add 20mL of KSM-9 strain to the medium, at a temperature of 30 oC , hydrolysis under the condition of pH 4 for 72 hours to obtain ethanol or; (4) co-liquefying lignite, red ...

Embodiment 2

[0025] Such as figure 1As shown, the method of using waste textiles to produce fuel and road asphalt modifier in this embodiment includes the following steps: (1) Pretreatment of waste textiles: first, the waste textiles are subjected to dedusting, impurity removal, bleaching, washing and drying in sequence. Dry processing, then cutting, tearing, opening and carding to obtain monofilaments; (2) dissolving the monofilaments obtained in step (1) with a lithium hydroxide / urea aqueous solution at a temperature of 253K and a mass concentration of 70% body, wherein the lithium hydroxide / urea aqueous solution is a mixed aqueous solution of 9wt% lithium hydroxide / 10wt% urea, and the cotton cellulose solution and undissolved chemical fibers are obtained after solid-liquid separation; (3) to the cotton cellulose solution Add 30mL of KSM-635 strain to the oC , hydrolysis at pH 8 for 50 hours to produce ethanol; (4) Co-liquefy long-flame coal, red mud catalyst, catalytic cracking oil sl...

Embodiment 3

[0028] Such as figure 1 As shown, the method of using waste textiles to produce fuel and road asphalt modifier in this embodiment includes the following steps: (1) Pretreatment of waste textiles: first, the waste textiles are subjected to dedusting, impurity removal, bleaching, washing and drying in sequence. Dry processing, then cutting, tearing, opening and carding to obtain monofilaments; (2) dissolving the monofilaments obtained in step (1) with a lithium hydroxide / urea aqueous solution at a temperature of 300K and a mass concentration of 90% body, wherein the lithium hydroxide / urea aqueous solution is a mixed aqueous solution of 5wt% lithium hydroxide / 18wt% urea, and after solid-liquid separation, cotton cellulose solution and undissolved chemical fibers are obtained; (3) to the cotton cellulose solution Add 5mL of 18mol / L homogeneous catalyst sulfuric acid, at a temperature of 50 o C. Hydrolyze for 45 hours under the condition of pH 4 to produce methanol; (4) Co-liquefy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com