Textile production automated management system and management method thereof

A technology of automatic management and management unit, applied in the field of textile production automation management system and its management and management system, can solve problems such as unfavorable enterprise production efficiency, influence of spinning quality, spinning quality problems, etc., to improve the level of production automation, Improve labor productivity and realize the effect of automatic management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

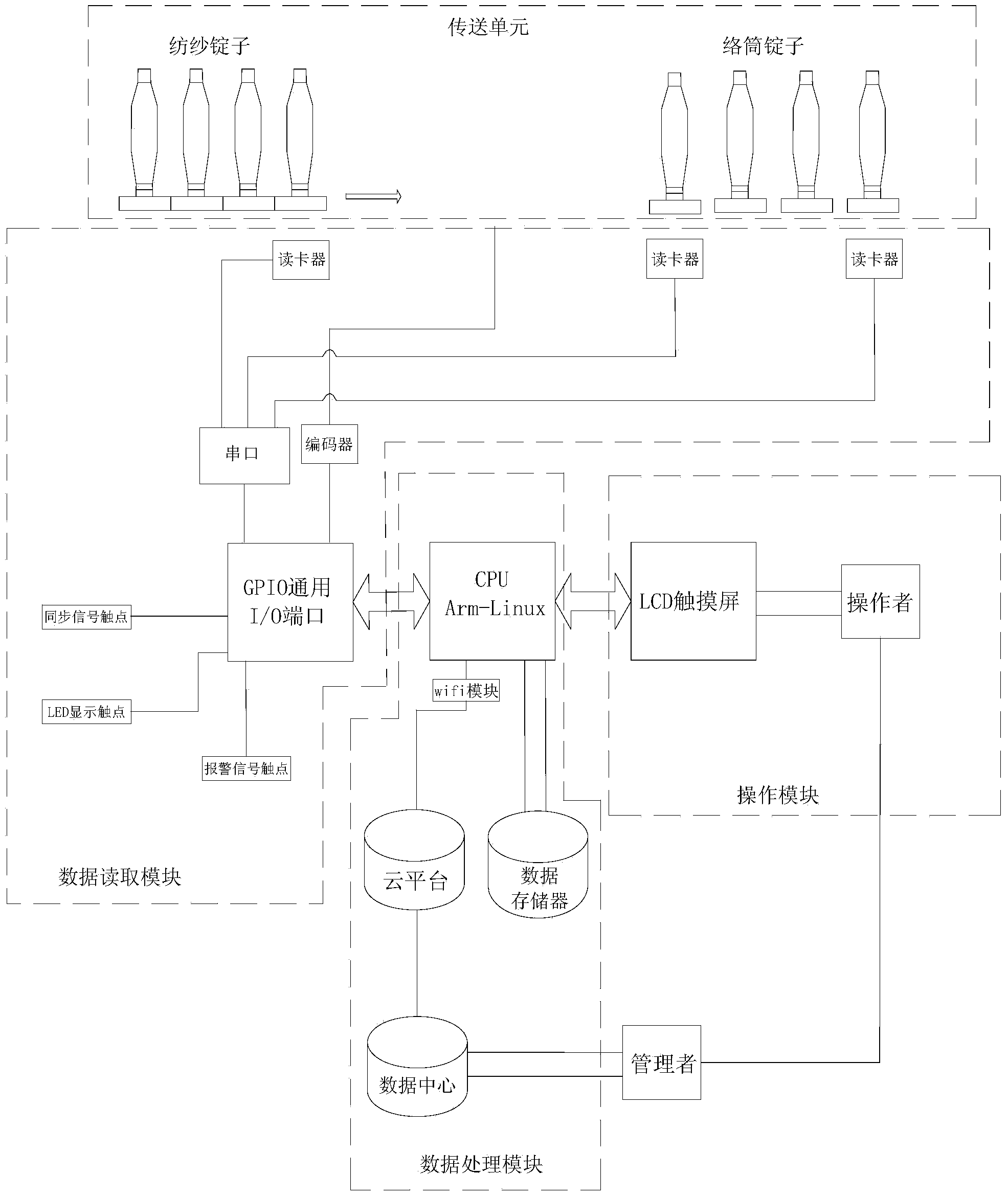

[0022] Such as figure 1 As shown, the textile production automation management system of the present invention includes a transmission unit and a management unit, the transmission unit is provided with spinning spindles and / or winding spindles arranged in sequence, and the management unit includes connected data Reading module, data processing module and operation module.

[0023] Each spinning spindle and / or winding spindle of the above-mentioned transmission unit is respectively provided with an RFID radio frequency tag with its own coded information; the above-mentioned data reading module corresponds to each specific spinning spindle and / or winding spindle. A card reader is provided to obtain the label information and working status information of each corresponding spinning spindle and / or winding spindle and transmit it to the data processing module for storage, analysis and processing.

[0024] As a preferred solution of the present embodiment, the above-mentioned techn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com