Production method of long-term soft and fluffy and hydroscopic and fast dry looped fabric

A technology of moisture-absorbing and quick-drying, production method, applied in the direction of fabrics, textiles, absorbent pads, etc., can solve the problems of increasing the weight loss rate of products, prone to filaments, poor segment shrinkage rate, etc., to achieve a wide range of product structures, easy to wet fast The effect of drying hair and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

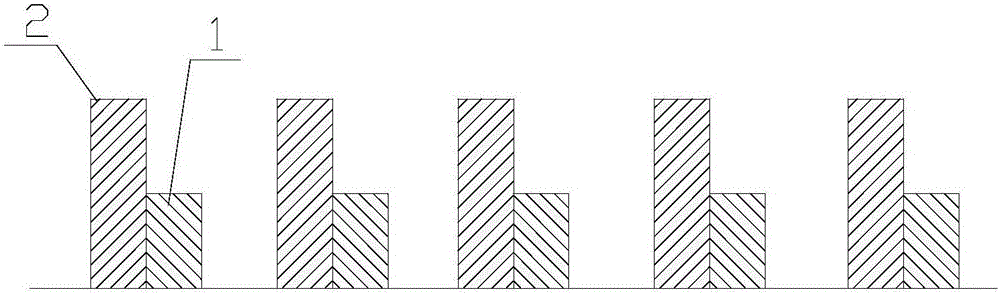

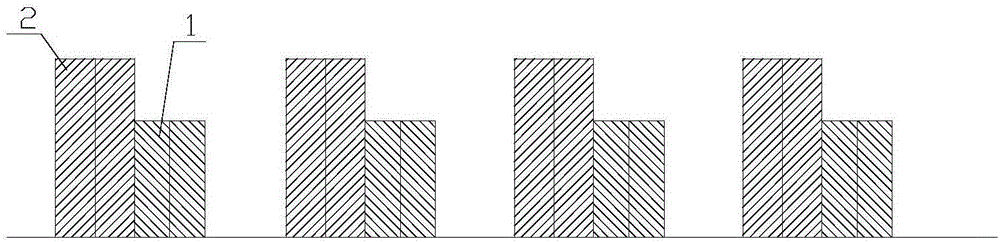

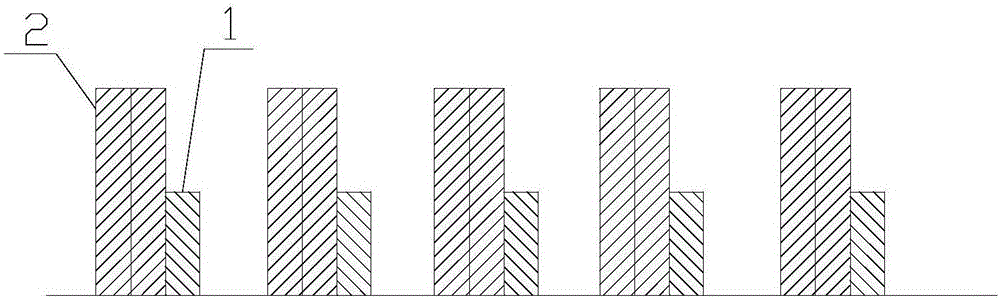

Image

Examples

Embodiment 1

[0034] A method for producing long-lasting, soft and fluffy, moisture-absorbing and quick-drying terry fabrics includes spinning, warping, sizing, weaving, dyeing and finishing, and the specific steps are:

[0035] 1.) Spinning:

[0036] Spinning of low-hot water shrinkage yarn: 16s pure cotton non-twisted yarn.

[0037] Spinning of high hot water shrinkage yarn: high shrinkage polyester cotton blended yarn, yarn count range: 16s, twist coefficient 350, fiber fineness: 1.33dtex, fiber length: 38mm, hot water shrinkage rate is 50%.

[0038] Ground warp and weft: 12s pure cotton yarn is used for ground warp, twist: 56t / m, and weft: 16s pure cotton yarn, twist 65t / dm.

[0039] 2) Warping: The warping speed is selected according to the yarn strength and the number of ends. The warping process speed: 550m / min, workshop temperature: 21-25 degrees, relative humidity: 65-70%.

[0040] 3) Sizing: The wool warp yarn adopts the sizing process of "light sizing, low pressure, light penetration, heavy...

Embodiment 2

[0047] A method for producing long-lasting, soft, fluffy, moisture-absorbing and quick-drying terry fabrics includes spinning, warping, sizing, weaving, dyeing and finishing, and the specific steps are:

[0048] 1.) Spinning:

[0049] Spinning of low hot water shrinkage yarn: 5s pure cotton yarn, twist coefficient 270.

[0050] Spinning of high hot water shrinkage yarn: high shrinkage polyester cotton blended yarn, yarn count: 5s, twist coefficient 300, fiber fineness: 4.0dtex, fiber length: 32mm, hot water shrinkage rate is 16%.

[0051] Ground warp and weft: 12s pure cotton yarn is used for ground warp, twist: 56t / m, and weft: 16s pure cotton yarn, twist 65t / dm.

[0052] 2) Warping: The warping speed is selected according to the yarn strength and the number of ends. The warping process speed: 300m / min, workshop temperature: 21-25 degrees, relative humidity: 65%.

[0053] 3) Sizing: The wool warp yarn adopts the sizing process of "light sizing, low pressure, light penetration, heavy coa...

Embodiment 3

[0060] A method for producing long-lasting, soft and fluffy, moisture-absorbing and quick-drying terry fabrics includes spinning, warping, sizing, weaving, dyeing and finishing, and the specific steps are:

[0061] 1.) Spinning:

[0062] Spinning of low hot water shrinkage yarn: 16s pure cotton yarn with 300 twist coefficient.

[0063] Spinning of high hot water shrinkage yarn: high shrinkage polyester cotton blended yarn, yarn count: 60s, twist coefficient 300, fiber fineness: 0.8dtex, fiber length: 51mm, hot water shrinkage rate is 65%.

[0064] Ground warp and weft: 12s pure cotton yarn is used for ground warp, twist: 56t / m, weft: 16s pure cotton yarn, twist 65t / dm.

[0065] 2) Warping: The warping speed is selected according to the yarn strength and the number of ends. The warping process speed: 700m / min, workshop temperature: 21-25 degrees, relative humidity: 70%.

[0066] 3) Sizing: The wool warp yarn adopts the sizing process of "light sizing, low pressure, light penetration, heav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fiber length | aaaaa | aaaaa |

| Fiber fineness | aaaaa | aaaaa |

| Fiber fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com