Intelligent textile production system based on automatic guided vehicle (AGV)

A production system and trolley technology, applied in general control systems, control/regulation systems, motor vehicles, etc., can solve problems such as long transformation period, reduced number of workers, and worker errors, so as to reduce automation transformation costs and transformation time, and reduce work Strength and the effect of improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

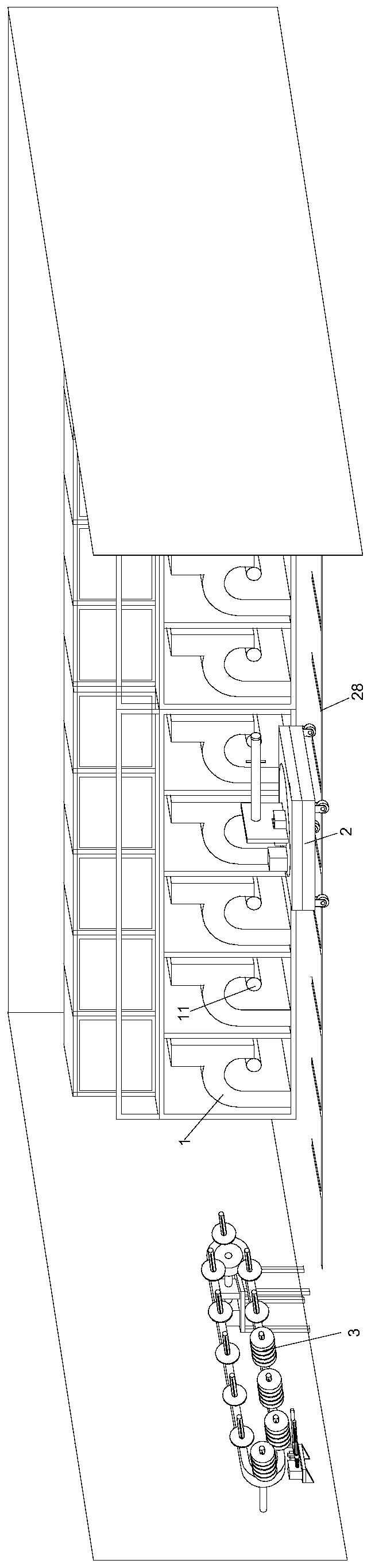

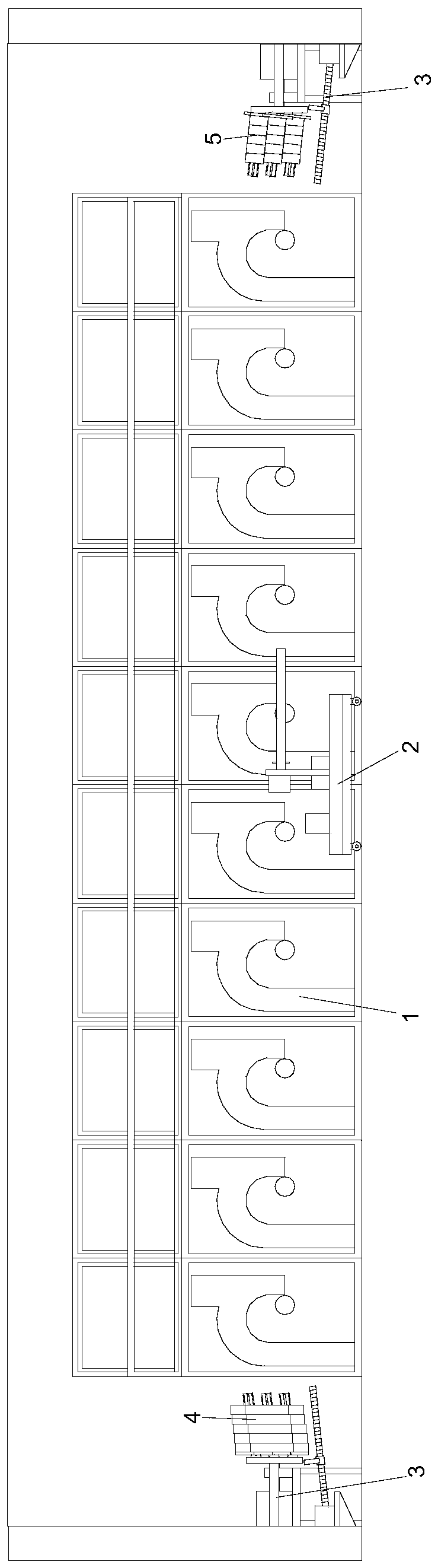

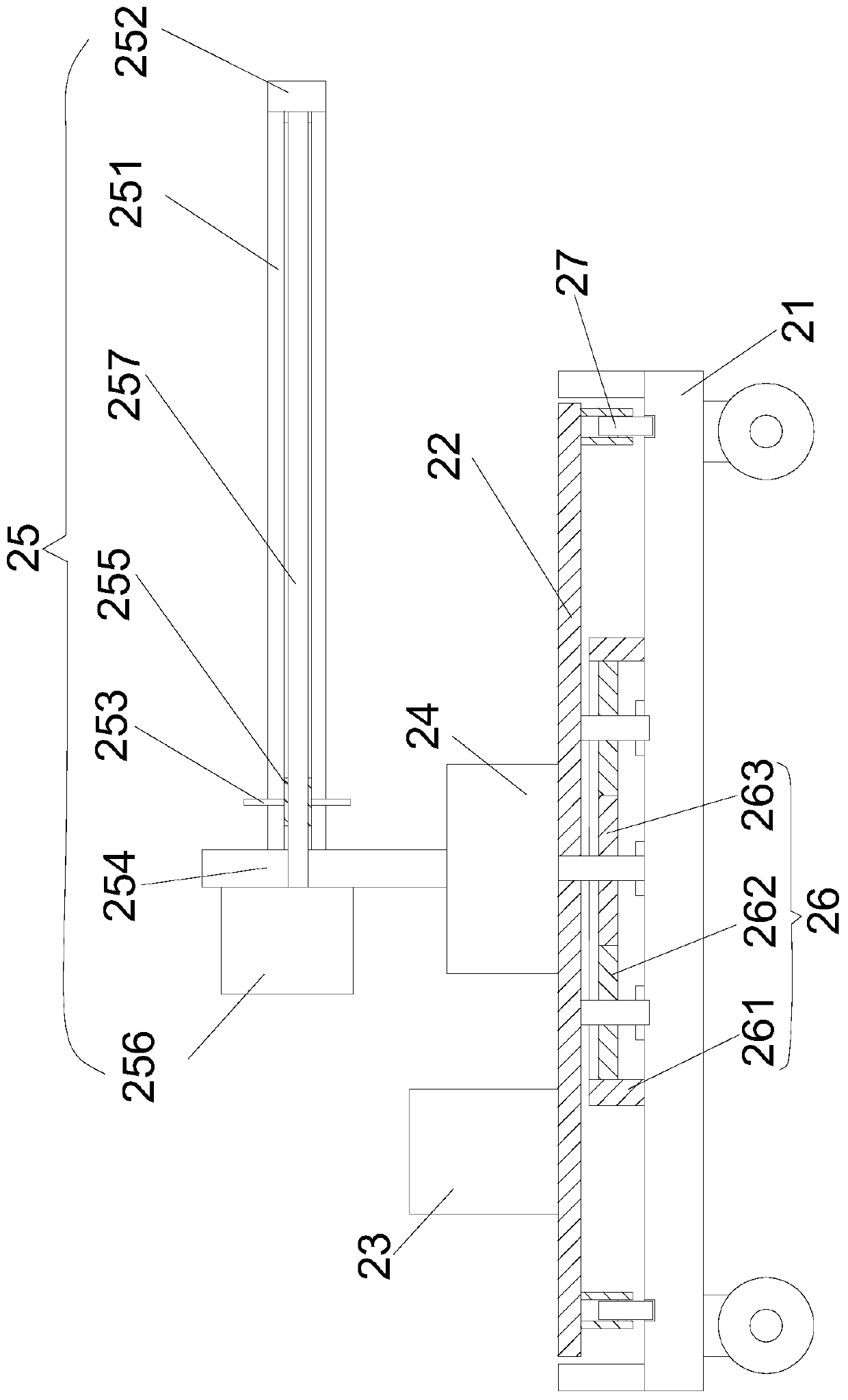

[0018] see Figure 1 to Figure 8 , the present invention provides an intelligent textile production system based on AGV trolley, including ACWW5T installed in the spinning and winding workshop, JRT type automatic winding machine 1 and AGV trolley 2, and also includes a paper tube or silk cake temporary storage mechanism 3. A turntable 22 is provided on the upper surface of the AGV trolley 2, and a planetary gear 262 and a series 26 are installed under the turntable 22. The planetary gear 262 and a series 26 include a ring gear 261, a planetary gear 262, and a sun gear 263. The planetary gear The rotating shaft of the wheel 262 is fixed on the lower surface of the turntable 22, and the upper surface of the AGV trolley 2 is provided with an annular chute for the revolution of the rotating shaft of the planetary wheel 262, and the first drive motor 24 is installed in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com