Processing method for pigment printing of plush product

A technology of paint printing and processing method, applied in the field of dyeing and finishing, can solve the problems of poor hand feeling and poor paint printing fastness, and achieve the effects of easy color matching, less environmental pollution, and saving post-treatment water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Light color (paint dosage 0.01-1%) pigment printing process formula.

[0017] (1) Pigment printing process of cashmere products

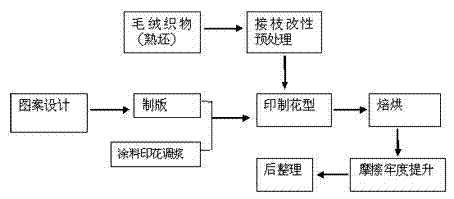

[0018] See attached figure 1 .

[0019] (2) Formula and process description

[0020] 1) Pre-treatment formulation process

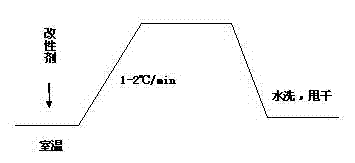

[0021] The pretreatment formula process is attached figure 2 As shown, modifier: 5% (o.w.f), bath ratio: 1:60-1:100, soak at 70°C for 20 minutes, and dry;

[0022] 2) Pigment printing formula and process

[0023] According to the following formulation standards, % is the mass fraction of the relative color paste:

[0024] Paint 0.5% 5g

[0025] Adhesive 8% 80g

[0026] Thickener 4% 40g

[0027] Softener 1% 10g

[0028] Glycerin, urea 3% 30g

[0029] Add water to 1000g;

[0030] 3) Color paste formula and instructions

[0031] Paint: 0.01-1%, urea: 3%, thickener: 3-4%, add water to: 100%;

[0032] 4) Baking

[0033] The clothes are dried after the paint is printed, and then baked under the following condit...

Embodiment 2

[0035] Medium depth (1-3% paint usage) pigment printing.

[0036] (1) Pigment printing process of cashmere products

[0037] See attached figure 1 .

[0038] (2) Formula and process description

[0039] 1) Pre-treatment formulation process

[0040] The pretreatment formula process is attached figure 2 As shown, modifier: 12% (o.w.f), bath ratio: 1:60-1:100, soak at 70°C for 20 minutes, and dry;

[0041] 2) Pigment printing formula and process

[0042] According to the following formulation standards, % is the mass fraction of the relative color paste:

[0043] Paint 2% 20g

[0044] Binder 10% 100g

[0045] Thickener 3.5% 35g

[0046] Softener 1% 10g

[0047] Glycerin, urea 3% 30g

[0048] Add water to 1000g;

[0049] 3) Color paste formula and instructions

[0050] Paint: 1-3%, urea: 3%, thickener: 3-4%, add water to 100%;

[0051] 4) Baking

[0052] The clothes are dried after the paint is printed, and then baked under the following conditions: baking temperat...

Embodiment 3

[0054] Dark color (3-6% paint content) pigment printing.

[0055] (1) Pigment printing process of cashmere products

[0056] See attached figure 1 .

[0057] (2) Formula and process description

[0058] 1) Pre-treatment formulation process

[0059] The pretreatment formula process is attached figure 2 As shown, modifier: 20% (o.w.f), bath ratio: 1:60-1:100, soak at 70°C for 20 minutes, and dry;

[0060] 2) Pigment printing formula and process

[0061] According to the following formulation standards, % is the mass fraction of the relative color paste:

[0062] Paint 4% 40g

[0063] Binder 15% 150g

[0064] Thickener 3.3% 33g

[0065] Softener 1% 10g

[0066] Glycerin, urea 3% 30g

[0067] Add water to 1000g;

[0068] 3) Color paste formula and instructions

[0069]Paint: 3-6%, urea: 3%, thickener: 3-4%, add water to 100%;

[0070] 4) Baking

[0071] The clothes are dried after the paint is printed, and then baked under the following conditions: baking temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com