Environmental-friendly pigment printing binding agent and preparation method thereof

A paint printing and adhesive technology, applied in dyeing, textile and papermaking, etc., can solve problems such as insufficient rubbing fastness, and achieve the effects of soft hand feeling, low production energy consumption and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

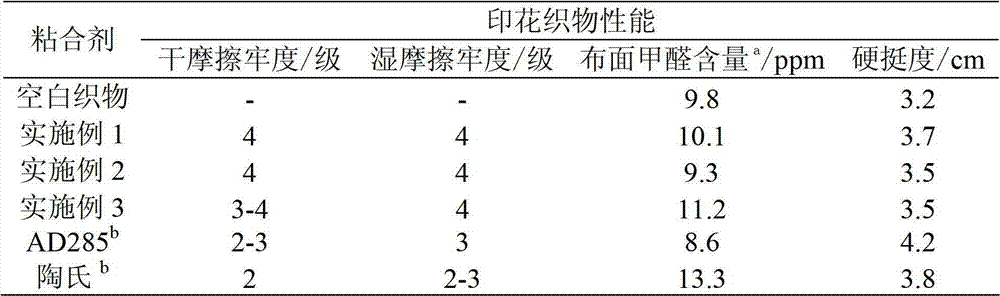

Examples

Embodiment 1

[0052] Add 2g sodium lauryl sulfate, 12g AEO9, 5g acrylic acid, 280g n-butyl acrylate, 30g styrene and 350g deionized water into the reaction vessel, stir and emulsify at 25°C for 45 minutes to prepare a pre-emulsion.

[0053] Dissolve 1.2g of ammonium persulfate in 100g of deionized water to prepare an initiator solution, then take 170g of pre-emulsion and 25g of initiator solution into a four-necked bottle, and raise the temperature to 80-82°C. When the blue light appears in the reaction emulsion, slowly add the remaining pre-emulsion and initiator dropwise, and keep warm at 82-85°C for 2.0 hours after the dropwise addition.

[0054] Then the temperature was lowered to 30°C, and a mixture of 10g of acrylic acid, 20g of n-butyl acrylate, 40g of methyl methacrylate, 30g of glycidyl methacrylate and 10g of hydroxyethyl methacrylate was added dropwise, and persulfuric acid was added dropwise. Ammonium solution (1g ammonium persulfate dissolved in 70g deionized water) and N,N,N′,...

Embodiment 2

[0062] Add 14g sodium dodecylbenzene sulfonate, 10g Pingpingjia 20, 8g methacrylic acid, 2g acrylamide, 200g 2-ethylhexyl acrylate, 50g styrene and 410g deionized water into the reaction vessel, at 40°C Stir and emulsify for 60 minutes to prepare a pre-emulsion.

[0063] Dissolve 1g of sodium persulfate in 50g of deionized water to prepare an initiator solution, then take 175g of pre-emulsion and 12.5g of initiator solution into a four-necked bottle, and raise the temperature to 80-82°C. When the blue light appears in the reaction emulsion, slowly add the remaining pre-emulsion and initiator dropwise, and keep warm at 82-85°C for 1.0 hour after the dropwise addition.

[0064] Then lower the temperature to 35°C, add dropwise a mixture of 10g methacrylic acid, 20g ethyl acrylate, 50g acrylonitrile, 20g hydroxypropyl acrylate and 10g diacetone acrylamide, and dropwise add ammonium persulfate solution (2g persulfate Ammonium dissolved in 100g deionized water) and vitamin C soluti...

Embodiment 3

[0069] Add 6g of sodium dodecyl sulfonate, 24g of Tween 80, 5g of acrylic acid, 5g of acrylamide, 240g of n-butyl acrylate, 40g of methyl methacrylate and 350g of deionized water into the reaction vessel, stir and emulsify at 35°C for 60 minutes to make a pre-emulsion.

[0070] Dissolve 1g of potassium persulfate in 50g of deionized water to prepare an initiator solution, then take 175g of pre-emulsion and 13g of initiator solution into a four-necked bottle, and raise the temperature to 80-82°C. When the blue light appears in the reaction emulsion, slowly add the remaining pre-emulsion and initiator dropwise, and keep warm at 80-82°C for 3.0 hours after the dropwise addition.

[0071] Then the temperature was lowered to 35°C, and a mixture of 5g of acrylic acid, 40g of ethyl acrylate, 40g of acrylonitrile, 10g of methacrylic acid ethylene glycol diester and 10g of N,N'-methylenebisacrylamide was added dropwise. At the same time, ammonium persulfate solution (2g ammonium persu...

PUM

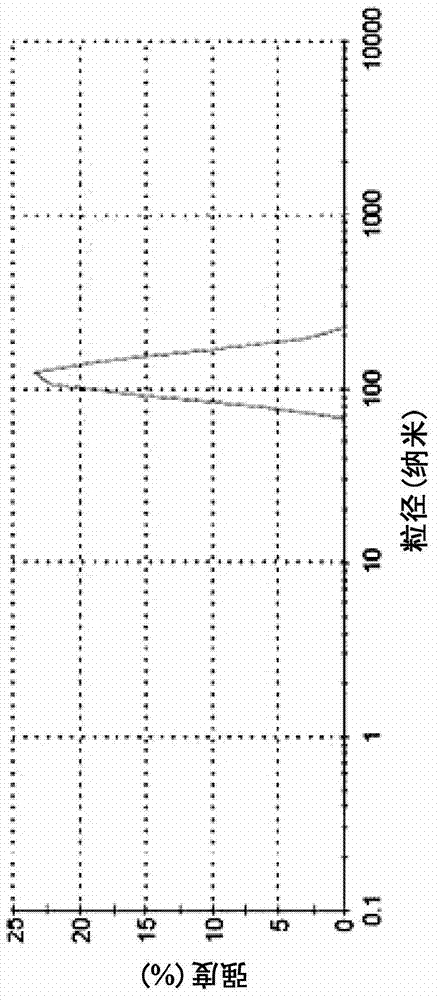

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com