Water-based resin-free pigment printing paste

A paint color paste, resin-free technology, applied in the field of paint, can solve the problems of precipitation, low cost performance, unusable, etc., to achieve the effect of high water resistance of paint film, wide application range and guaranteed stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

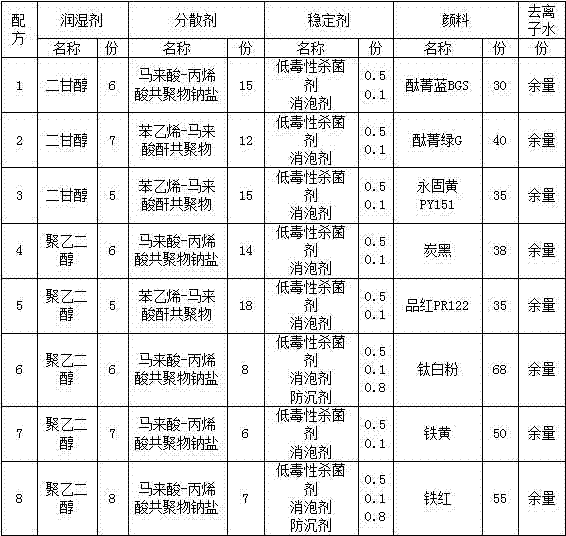

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the following examples are used to describe the present invention in detail.

[0021] Water-based resin-free paint color paste is a commonly used pigment color paste, which needs to meet the following requirements: high pigment content, good fluidity, no caking, no precipitation, no mold, no coarseness after long-term storage ; High solid content, low foam; it can be used after melting when it is frozen, VOC is as low as possible, and does not contain harmful substances; it has good compatibility with leather resin, small particle size and narrow distribution, fineness control is less than 5 microns, the product Stable viscosity; strong tinting power, the color strength of the pigment slurry is controlled at (100±5)%; the color difference (△E) between batches is controlled within 0.8; the pH value is controlled at 4.5~7, no air drying, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com