Metal glaze printing ink for ceramic ink-jet printing and preparation method thereof

A ceramic inkjet and metal glaze technology, applied in ink, applications, household appliances, etc., can solve the problems of reducing the color and gloss effect of metal glaze, affecting the crystallization effect of metal glaze, etc., and achieve good inkjet printing performance and quality Good stability and the effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

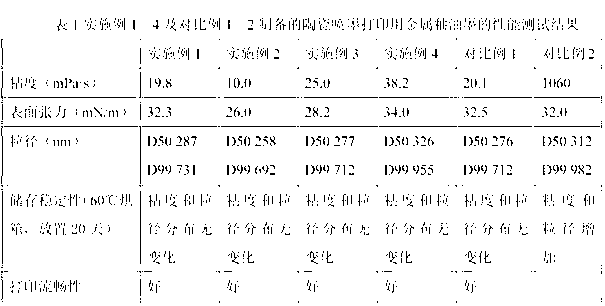

Examples

Embodiment 1

[0024] An ink for ceramic inkjet printing, composed of the following components by mass percentage: 50% metallic glaze, 6% dispersant (BYK163), 3% alkyd resin (Novalkyd 2510AB80), leveling agent (Tego Flow300 ) 0.1%, anti-settling agent (Disparlon NS-5501) 0.1%, defoamer (BYK051) 0.3%, diethylene glycol methyl ether 30%, diethylene glycol propyl ether 10.5%.

[0025] Among them, the metal glaze, its raw material is composed of the following components by mass: SiO 2 40 parts, Al 2 o 3 12 copies, K 2 O 1 part, Na 2 O 1 part, CaO 0.5 part, MgO 0.5 part, Fe 2 o 3 15 copies, P 2 o 5 18 parts, ZnO 3 parts; (because the total is less than 100% in %, it is changed to parts by mass) its preparation method includes the following steps: weighing each raw material component according to the proportion, mixing and sintering at 1000°C for 1h , and then pulverized and ground to 250-400 mesh to obtain a metallic glaze.

Embodiment 2

[0027] A metallic glaze ink for ceramic inkjet printing, consisting of the following components by mass percentage: 40% metallic glaze, 4% dispersant (Nuosperse FX9086), 3% alkyd resin (Novalkyd 3732X70), leveling agent (Tego Flow370) 0.1%, anti-settling agent (Disparlon NS-5501) 0.1%, defoamer (BYK052) 0.3%, diethylene glycol propyl ether 10.5%, propylene glycol methyl ether acetate 42%.

[0028] Among them, the metal glaze, its raw material is composed of the following components by mass: SiO 2 30 parts, Al 2 o 3 14 copies, K 2 O 0.5 parts, Na 2 O 0.5 parts, CaO 2 parts, MgO 1 part, Fe 2 o 3 16 copies, P 2 o 5 20 parts, 1 part of ZnO; its preparation method includes the following steps: weighing each raw material component according to the proportion, mixing, sintering at 900°C for 1 hour, and then pulverizing and grinding to 250-400 mesh to obtain a metal glaze.

Embodiment 3

[0030]A metal glaze ink for ceramic inkjet printing, composed of the following components by mass percentage: 40% metal glaze, 4% dispersant (Tego 710), 2% acrylic resin (NeoCryl B731), leveling agent ( Afcona 3700) 0.2%, anti-settling agent (Disparlon 6650) 0.1%, defoamer (BYK051) 0.2%, diethylene glycol butyl ether 35%, ethylene glycol ether acetate 18.5%.

[0031] Among them, the metal glaze, its raw material is composed of the following components by mass: SiO 2 55 parts, Al 2 o 3 10 copies, K 2 2 parts of O, Na 2 O 1 part, CaO 1 part, MgO 1 part, Fe 2 o 3 12 copies, P 2 o 5 24 parts, ZnO 2 parts; its preparation method includes the following steps: weighing each raw material component according to the proportion, mixing and sintering at 800°C for 1 hour, and then crushing and grinding to 250-400 mesh to obtain a metal glaze.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com