POSS/polyurethane aqueous composite paint and preparation method thereof

A composite coating and polyurethane technology, used in polyurea/polyurethane coatings, coatings, latex paints, etc., can solve the problems of poor suspension stability and rheology, affect the performance of water-based composite coatings, and large specific surface area, and achieve storage stability. Good properties, excellent UV resistance, and high film quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Add 17.7g of distilled water into a 250mL round bottom flask containing 10g of trichloromethylsiloxane and 100mL of acetone under stirring conditions, raise the temperature to 50°C, and reflux the solution for 48 hours. After the reaction, the collected white solid was washed with acetone, filtered and dried in vacuum at 45°C for 8 hours, then suspended with 20 times the weight of pyridine and stirred overnight, and finally the pyridine solution was poured into an equal volume of concentrated hydrochloric acid and ice The precipitate was collected, washed with water until neutral, and dried under vacuum at 45 °C overnight. Finally, after exhaustive extraction with diethyl ether, the unblocked POSS was obtained.

[0028] Mix 4.0g of the above-mentioned uncapped POSS, 2g of silane coupling agent KH-550 and 20mL of tetrahydrofuran evenly, control the temperature at 55°C, then add 5mL of triethylamine and 60mL of tetrahydrofuran, and after the reaction time lasts for 36 hou...

Embodiment 2

[0032] Same as Example 1, but the ratio 100:1:1:100 of isocyanate-terminated polyurethane prepolymer, POSS, dibutyltin dilaurate and acetone was changed to 100:2:1:100.

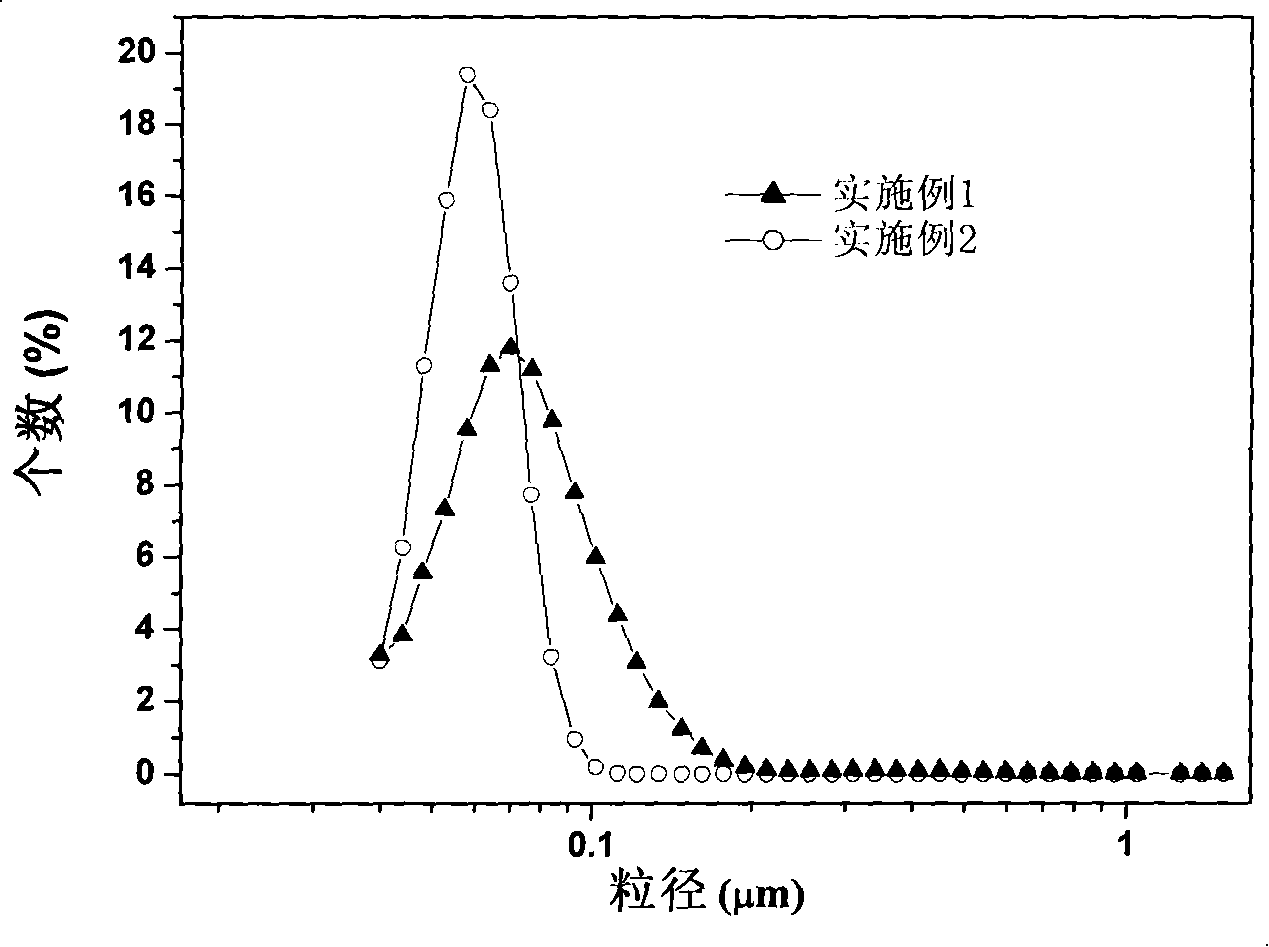

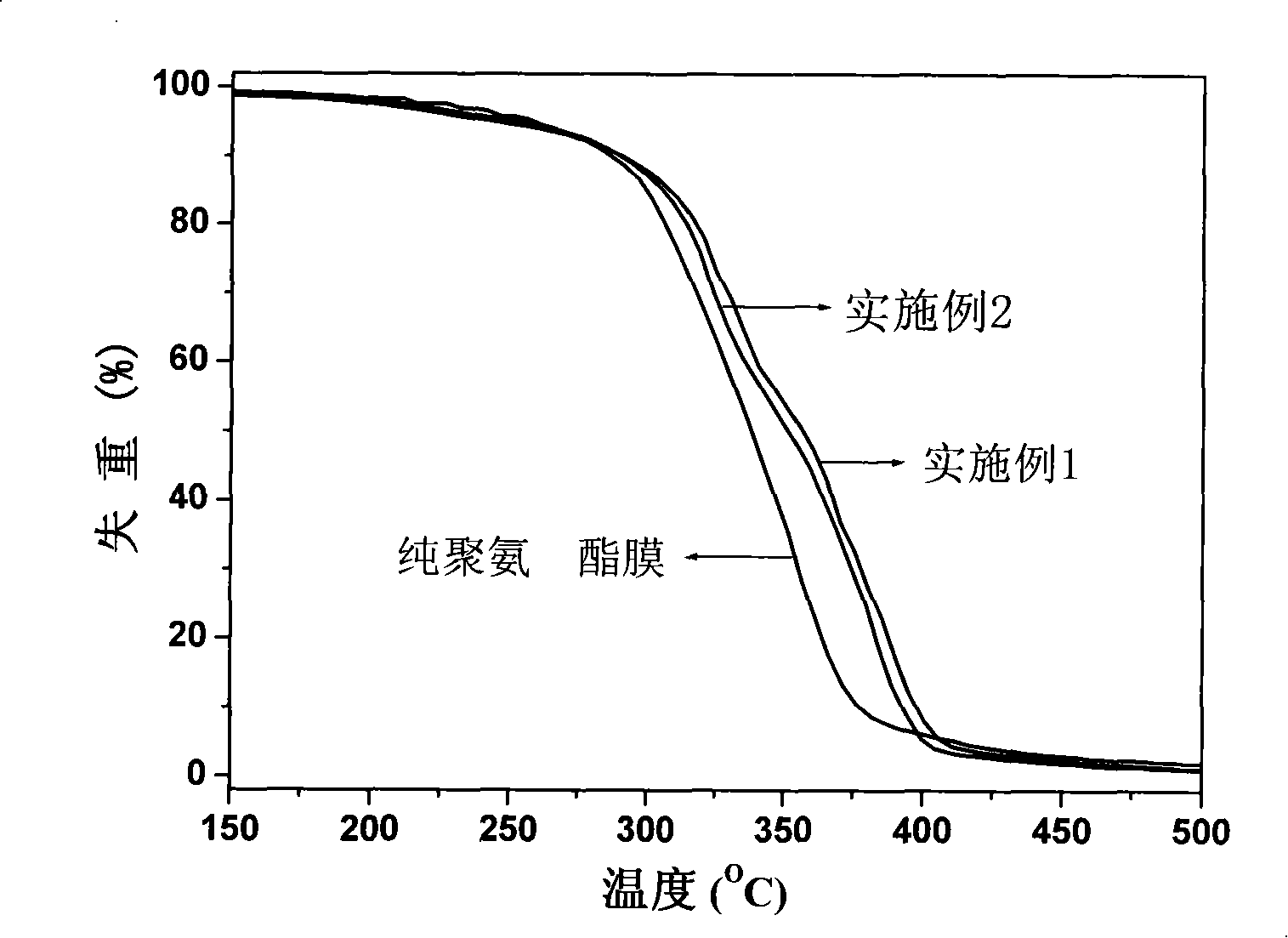

[0033] The coating performance of this POSS / polyurethane water-based composite coating is shown in Table 1, and its particle size distribution is shown in Table 1. figure 2 , its thermal properties and UV-visible transmittance are shown in image 3 and Figure 4

Embodiment 3

[0035] Same as Example 1, same as Example 1, but the ratio 100:1:1:100 of isocyanate-terminated polyurethane prepolymer, POSS, dibutyltin dilaurate and acetone is changed to 100:5:1:100 .

[0036] The film properties of the POSS / polyurethane water-based composite coating are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com