Water-based environment-friendly matte aluminum powder metallic paint and preparing method thereof

A metallic paint and water-based technology, applied in coatings, electrophoretic coatings, etc., can solve the problems of water-based paints such as easy sagging, shrinkage cavities, pinholes, etc., and achieve the effect of neatly arranged silver powder, good leveling, and improved silver powder arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

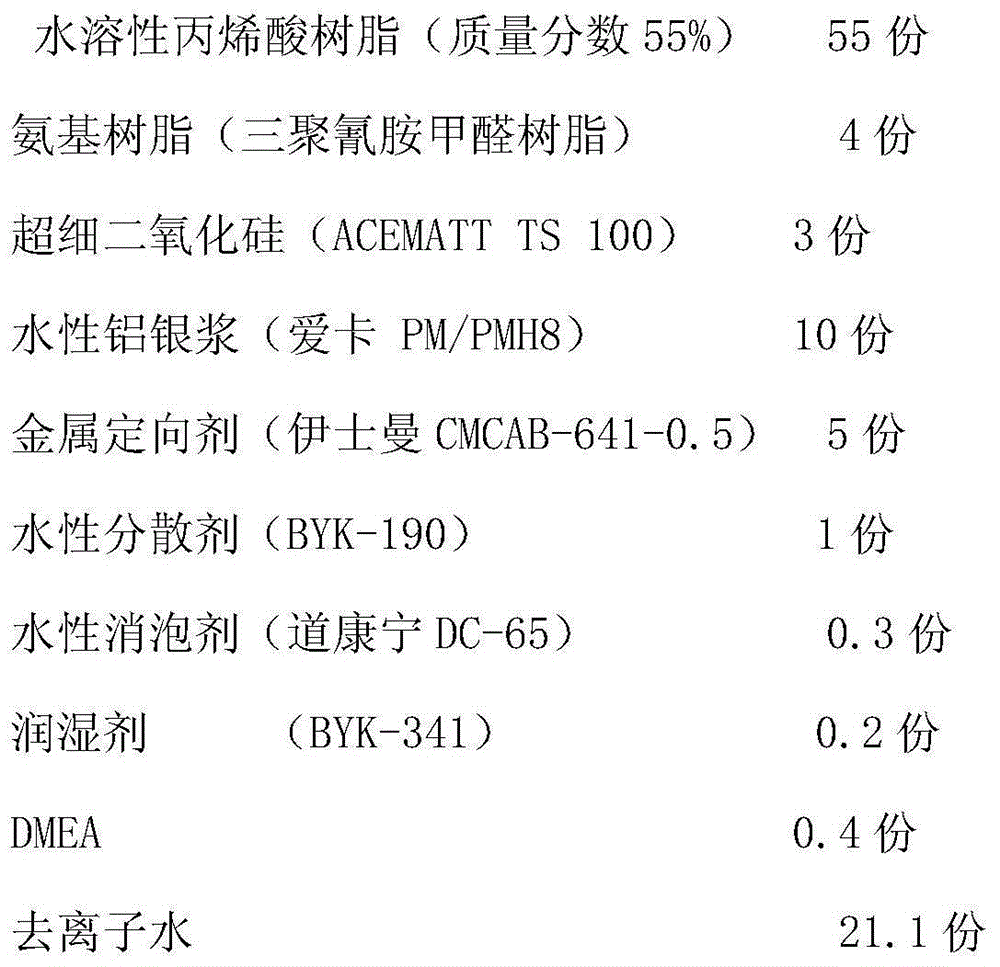

[0021] (1) Formula and the weight ratio of each component:

[0022]

[0023] (2) Preparation method:

[0024] 55 parts of water-soluble acrylic resin (mass fraction 55%), 4 parts of amino resin (melamine formaldehyde resin), 3 parts of ultrafine silica (ACEMATTTS100), 5 parts of metal orientation agent (Eastman CMCAB-641-0.5) , 1 part of water-based dispersant (BYK-190), 0.3 part of water-based defoamer (Dow Corning DC-65), 0.2 part of wetting agent (BYK-341), 21.1 parts of deionized water into the high-speed disperser according to the above ratio , stirring at a speed of 800-1200rpm, adding 0.4 parts of amine neutralizer DMEA while stirring, until the metal directional agent (Eastman CMCAB-641-0.5) in the mixture is completely dissolved, and the pH value of the test coating is 7.5- 8. Then add 10 parts of water-based aluminum-silver paste (Aika PM / PMH8), and stir evenly at low speed.

[0025] (3) Effect:

[0026] Conduct electrophoresis test on 6063 aluminum plate of 5...

Embodiment example 2

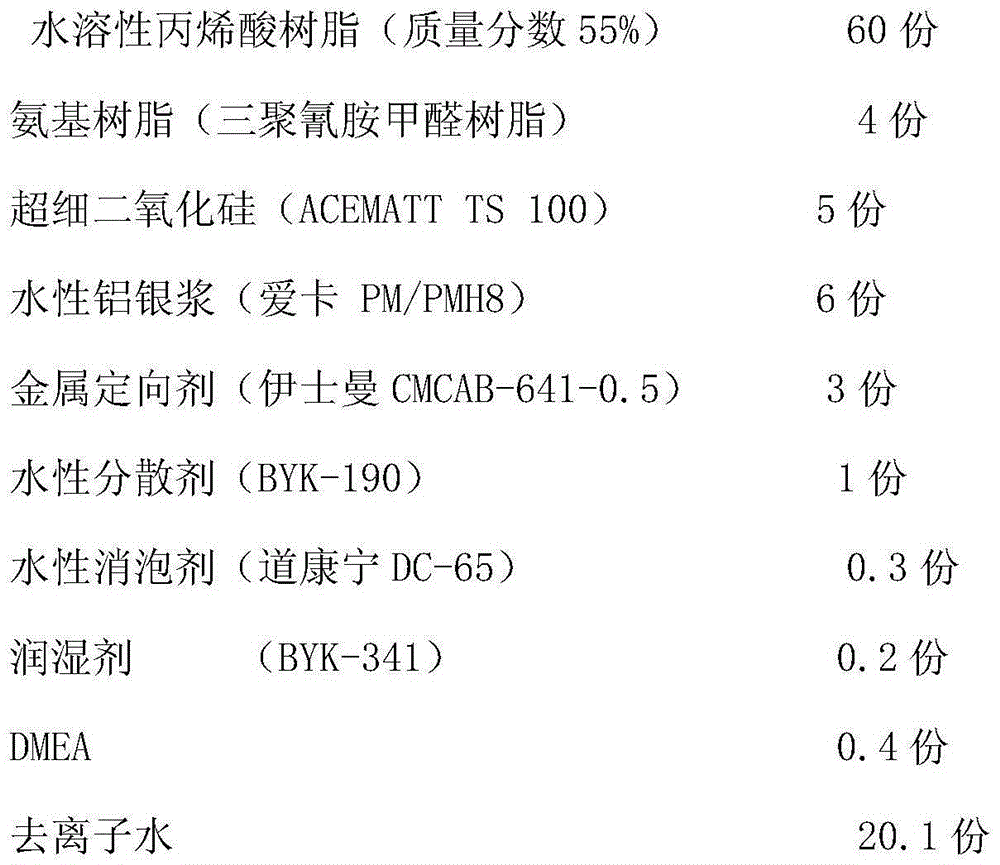

[0028] (1) Formula and the weight ratio of each component:

[0029]

[0030] (2) Preparation method:

[0031] 60 parts of water-soluble acrylic resin (mass fraction 55%), 4 parts of amino resin (melamine formaldehyde resin), 5 parts of ultrafine silica (ACEMATTTS100), 3 parts of metal orientation agent (Eastman CMCAB-641-0.5) , 1 part of water-based dispersant (BYK-190), 0.3 part of water-based defoamer (Dow Corning DC-65), 0.2 part of wetting agent (BYK-341), 20.1 parts of deionized water into the high-speed disperser according to the above ratio , stirring at a speed of 800-1200rpm, adding 0.4 parts of amine neutralizer DMEA while stirring, until the metal directional agent (Eastman CMCAB-641-0.5) in the mixture is completely dissolved, and the pH value of the test coating is 7.5- 8. Then add 6 parts of water-based aluminum silver paste (Aika PM / PMH8), and stir evenly at low speed. (3) Effect:

[0032] Conduct electrophoresis test on 6063 aluminum plate of 50×150mm to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| luster | aaaaa | aaaaa |

| luster | aaaaa | aaaaa |

| luster | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com