Normal-temperature curing conductive adhesive and preparation method thereof

A room temperature curing, conductive adhesive technology, used in the field of conductive adhesives, can solve the problems of long curing time at room temperature, corrosion of the bonded substrate, low bonding strength, etc., achieving short curing time at room temperature, fast drying speed, volume The effect of low resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

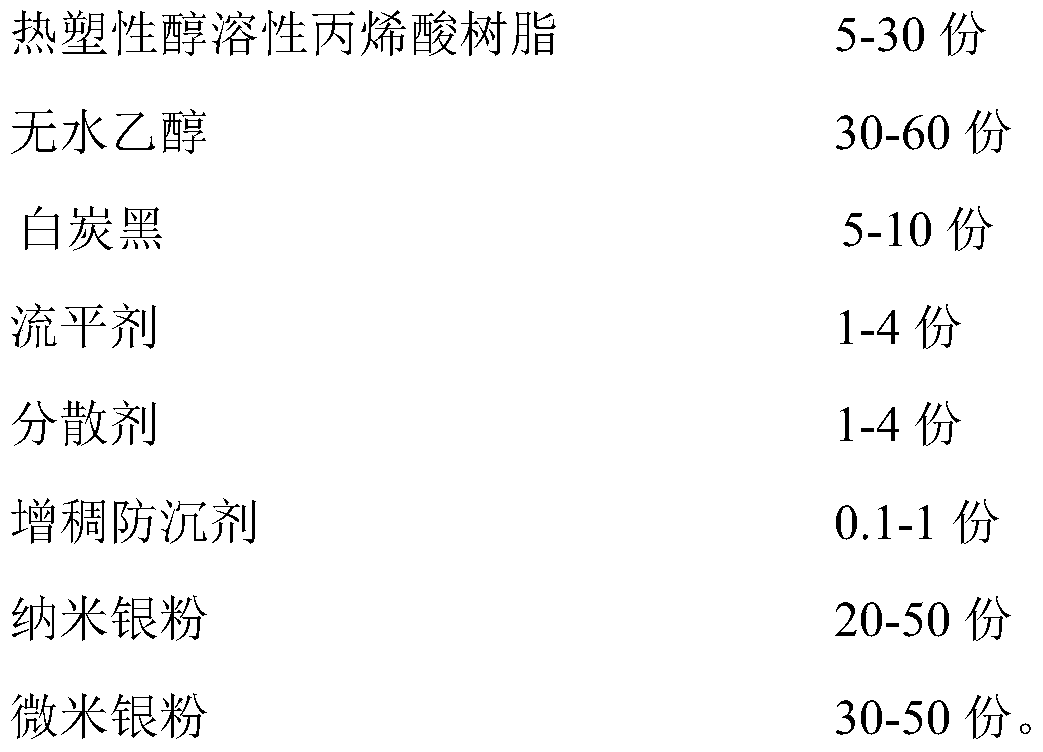

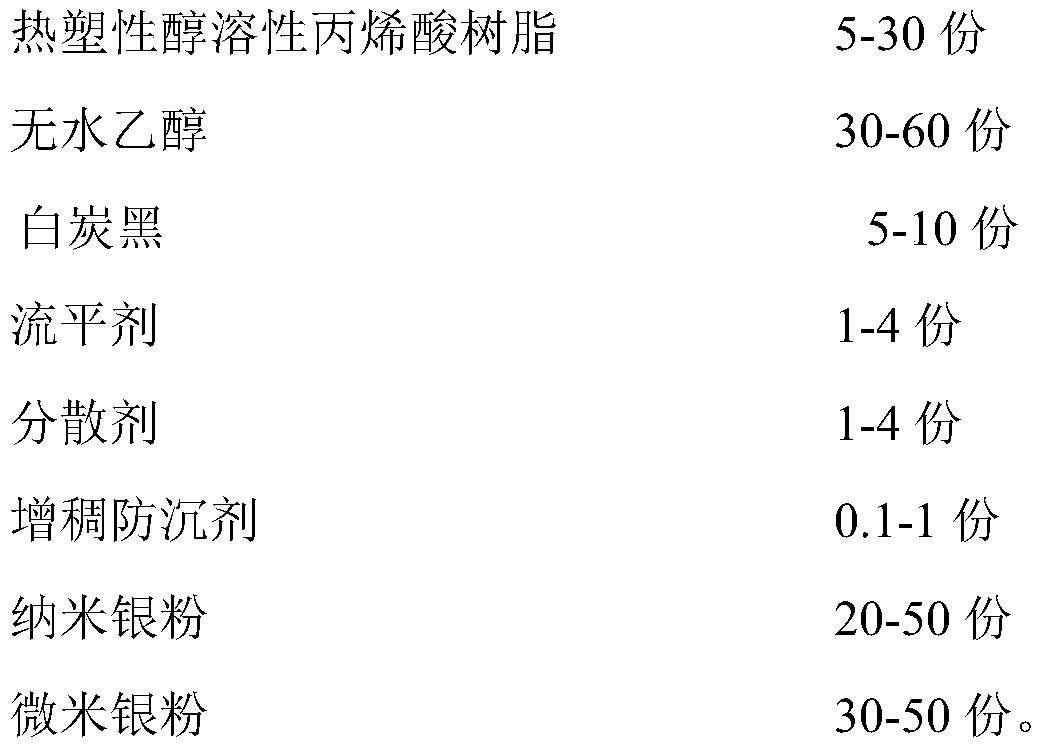

[0061] A normal temperature curing conductive adhesive is prepared by the following method:

[0062] (1) At 25°C, 10 parts of thermoplastic alcohol-soluble acrylic resin B725 with a viscosity of 3000 cps and 30 parts of absolute ethanol were added to the reactor and stirred and mixed for 5 hours;

[0063] (2) At 25°C, mix 1 part of alcohol ether solvent dispersant LD-1211, water-oil general-purpose polyether modified polysiloxane leveling agent SP-931, 0.3 part of polyamide wax, 5 parts White carbon black H18, 20 parts of nano-silver powder with a particle diameter of 100nm and 30 parts of micron silver powder with a particle diameter of 1 μm were added to the mixture obtained in step (1) and stirred for 2 hours;

[0064] (3) The mixture obtained in step (2) is ball-milled for 5 hours, and the fineness of the test material is less than 3 μm before collection. After collection, it is filtered with a 400-mesh sieve, and after filtration, it is filled into a syringe for storage. ...

Embodiment 2

[0067] (1) At 25°C, 10 parts of thermoplastic alcohol-soluble acrylic resin B731 with a viscosity of 6000 cps and 35 parts of absolute ethanol were added to the reaction kettle and stirred and mixed for 5 hours;

[0068] (2) Under the condition of 25°C, 1 part of alcohol ether solvent dispersant BYK-P104S, 1 part of water-oil general-purpose polyether modified polysiloxane leveling agent SP-963, 0.1 part of polyamide wax, 5 parts of white carbon black H20, 40 parts of particle diameters are the nanometer silver powder of 150nm and 30 parts of particle diameters are the micron silver powder of 1 μm join in the mixture gained in step (1) and stir and mix for 2 hours;

[0069] (3) The mixture obtained in step (2) is ball-milled for 5 hours, and the fineness of the test material is less than 3 μm before collection. After collection, it is filtered with a 400-mesh sieve, and after filtration, it is filled into a syringe for storage.

[0070] The prepared conductive adhesive was cur...

Embodiment 3

[0072] (1) At 25°C, 15 parts of thermoplastic alcohol-soluble acrylic resin B736 with a viscosity of 4000 cps and 35 parts of absolute ethanol were added to the reaction kettle and stirred and mixed for 5 hours;

[0073] (2) Under the condition of 25°C, 1 part of alcohol ether solvent dispersant BYK-163, 1 part of water-oil general-purpose polyether modified polysiloxane leveling agent SP-983, 0.2 part of polyamide wax, 5 parts of white carbon black H21, 30 parts of nanometer silver powders with a particle diameter of 100nm and 35 parts of micron silver powders with a particle diameter of 1 μm were added to the mixture obtained in step (1) and the time for stirring and mixing was 2 hours;

[0074] (3) The mixture obtained in step (2) is ball-milled for 5 hours, and the fineness of the test material is less than 3 μm before collection. After collection, it is filtered with a 400-mesh sieve, and after filtration, it is filled into a syringe for storage.

[0075] The prepared con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com