Method for transferring pattern of textile fabric

A transfer method and fabric technology, which can be used in dyeing, textile and paper making, etc., can solve the problems of blurred patterns, difficult humidity control, and different tight tissue structures, so as to reduce production costs and reduce dyeing. Printing difficulty and saving processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Polyethylene oxide is dissolved in water to prepare a 2% (w / w) solution, coated on the BOPP film with a gravure printing machine, dried, and rolled up for later use. Then 20% reactive black kn-b, 5% sodium alginate, and 75% water are prepared into ink according to the weight percentage, and the pattern is selected. After printing the pattern with a rotary screen printing machine, it is wound up. Lay the above-mentioned printed transfer film with the pre-moistened and dried cotton knitted fabric, and enter the roller heat transfer machine together, adjust the temperature to 120°C, and adjust the pressure to 15Kg / cm 2 , after transfer printing, wet the fabric and the transfer film on the reverse side, then wrap it with plastic film to prevent water loss, put it in a constant temperature room at 15°C, and cold pile it for 16 hours, finally tear off the PET film, and perform post-treatment such as washing with water process to complete the transfer printing.

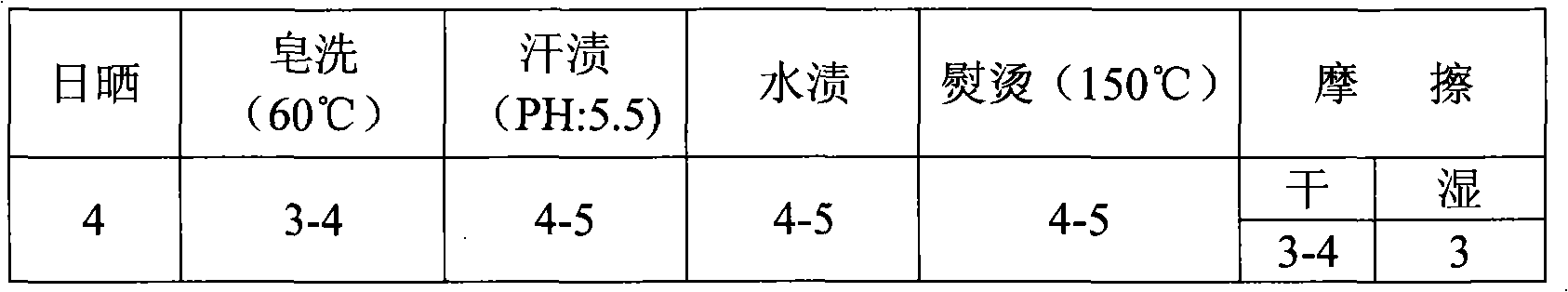

[0032] Throu...

Embodiment 2

[0036] Polypropylene oxide was dissolved in ethylene dichloride to form a 30% (w / w) solution, which was coated on 100 grams of white paper with a knife coater, dried, and rolled up for later use. Then 0.5% of weak acid red B, 10% of polyvinyl acetal resin, and 89.5% of methyl alcohol are made into ink by weight percentage, and the pattern is selected. After printing the pattern with a gravure printing machine, it is wound up. Lay the above printed transfer paper with the pre-moistened and dried silk fabric, put them into the flatbed transfer printing machine together, adjust the temperature to 150°C, and adjust the pressure to 25Kg / cm 2 , After transfer printing, put the fabric together with the transfer paper in a steamer for 45 minutes at a temperature of 102°C. Finally, the transfer paper is torn off, and post-treatment processes such as washing are performed to complete the transfer printing.

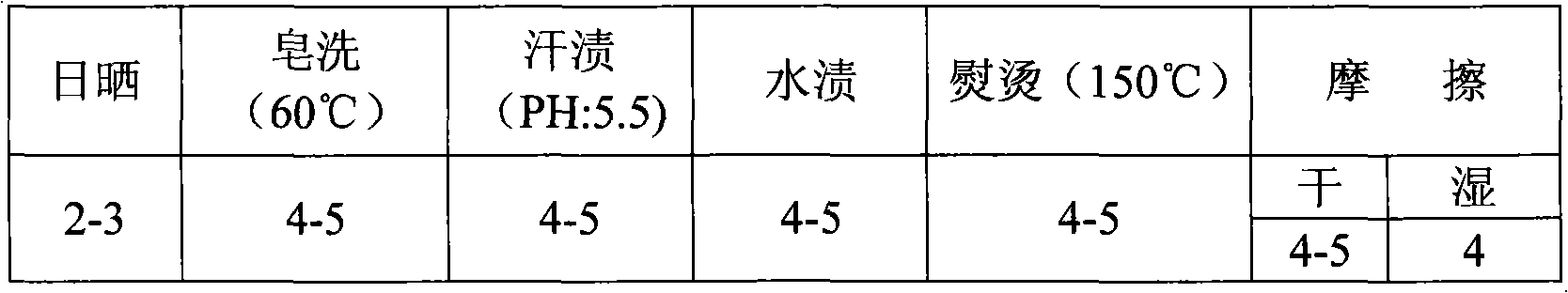

[0037] Through the test, the fastness indicators of the printed pattern are sh...

Embodiment 3

[0041]Heat the polyethylene oxide to 180°C to melt it completely, then evenly coat the polyethylene oxide on the PET film with a hot-melt coater, and roll it up for later use. Then buy ready-made active yellow inkjet ink, choose the pattern, and use Muto inkjet printer for inkjet printing. Cut the above-mentioned printed transfer film into the size of the garment, fit it together with the pre-moistened and dried sweater garment, put it into the flat-bed transfer printing machine, adjust the temperature to 160°C, and adjust the pressure to 30Kg / cm 2 , After transfer printing, tear off the transfer film, put the fabric and steam in a steamer for 60 minutes at a temperature of 102°C. Finally, post-processing such as water washing is carried out to complete the transfer printing.

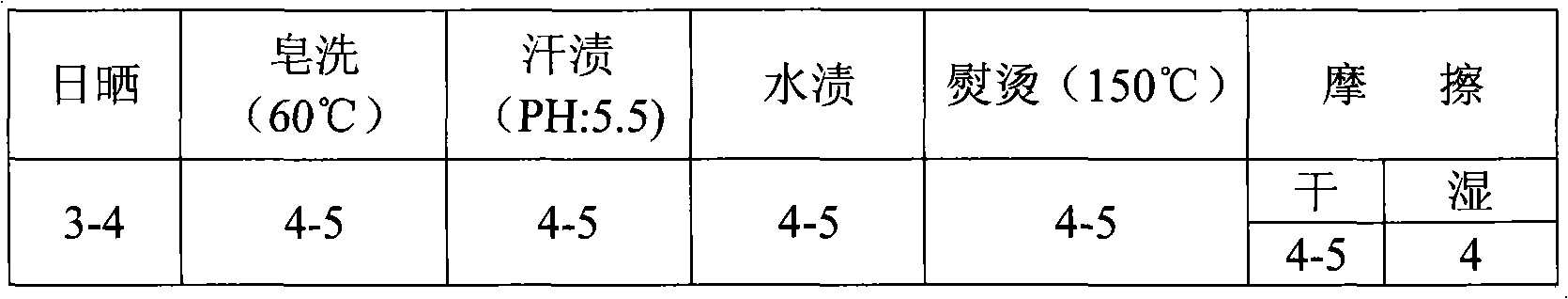

[0042] Through the test, the fastness indicators of the printed pattern are shown in Table 3, which is similar to the effect of wet transfer printing.

[0043] table 3

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com