Salt-resistive thickening agent as well as preparation method and application thereof

A thickener and salt-tolerant technology, which is applied in the field of salt-tolerant thickeners, can solve problems such as the influence of salt-resistant performance, the effect of association effects, and the difficulty of uniform copolymerization, so as to achieve stable salt-resistant performance, easy control, and high The effect of cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

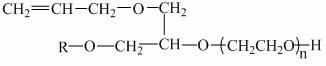

[0024] Add 60g of acrylic acid and 0.6g of N,N-methylenebisacrylamide into the reaction vessel, neutralize with ammonia water until the pH value of the mixture is 6.8; weigh 40g of kerosene and 5.0g of Span-80, and mix the two After fully mixing, slowly add the mixed solution neutralized by acrylic acid, 5.4g of salt-tolerant monomer (A) and 0.18g of ammonium persulfate. The general structural formula of salt-tolerant monomer (A) is:

[0025] ,

[0026] Wherein, R is n-dodecyl, and the degree of polymerization n is 20.

[0027] After stirring at a speed of 1800 rpm, fully emulsified into a viscous liquid, change to a stirring speed of 90 rpm, blow nitrogen, heat, control the temperature at 60 ° C for 2.5 hours, cool to room temperature, add and 5.0g Tween-80, stirring at a speed of 1200 rpm for 35 minutes to obtain a salt-tolerant thickener.

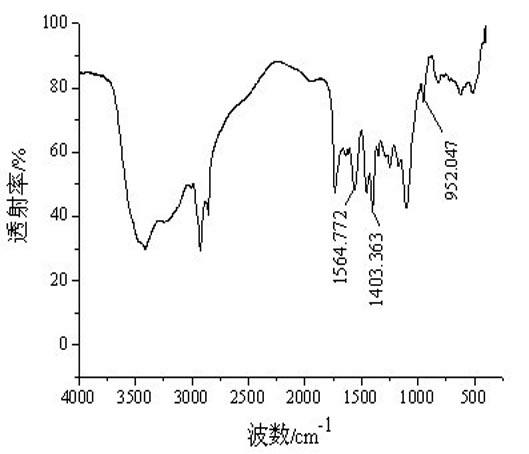

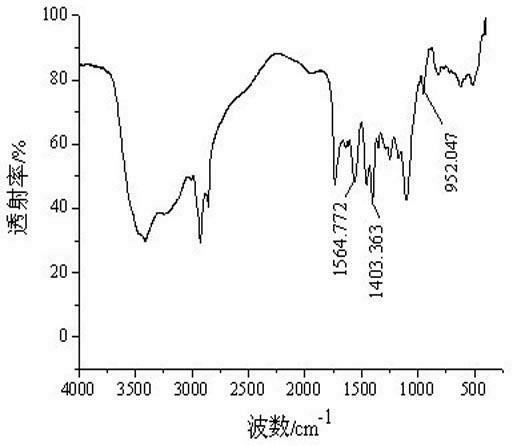

[0028] See attached figure 1 , which is the infrared spectrogram of the salt-tolerant thickener prepared in the present embodiment...

Embodiment 2

[0030] Add 60g of acrylic acid and 0.72g of N,N-methylenebisacrylamide into the reaction vessel, neutralize with sodium hydroxide solution until the pH of the mixture is 6.5; then weigh 36g of odorless kerosene and 3.6g of Span-80 After fully mixing the two, slowly add the mixed solution after neutralization of acrylic acid, 4.8g of salt-tolerant monomer (A) and 0.12g of sodium persulfate. The general structural formula of salt-tolerant monomer (A) is:

[0031] ,

[0032] Among them, R is n-hexadecyl, and the degree of polymerization n is 30; after being stirred at a speed of 1500 rpm and fully emulsified into a viscous liquid, the stirring speed is changed to 80 rpm, nitrogen gas is passed, heating is carried out, and the temperature is controlled. After reacting at 55° C. for 3 hours, cool down to room temperature, add 3.6 g of Tween-80, and stir at 1300 rpm for 30 minutes to obtain a salt-tolerant thickener.

Embodiment 3

[0034]Add 60g of acrylic acid and 0.9g of N,N-methylenebisacrylamide into the reaction vessel, neutralize with sodium hydroxide solution until the pH value of the mixture is 7.0; then weigh 42g of kerosene and 6.3g of Span-80, After fully mixing the two, slowly add the mixed solution after neutralization of acrylic acid, 6.0g of salt-tolerant monomer (A) and 0.24g of potassium persulfate. The general structural formula of salt-tolerant monomer (A) is:

[0035] ,

[0036] Among them, R is n-octadecyl, and the degree of polymerization n is 40; after being stirred at a speed of 2000 rpm and fully emulsified into a viscous liquid, the stirring speed is changed to 120 rpm, nitrogen gas is passed, heating is carried out, and the temperature is controlled. After reacting at 65° C. for 2.8 hours, cool down to room temperature, add 6.3 g of Tween-80, and stir at a speed of 1500 rpm for 32 minutes to obtain a salt-tolerant thickener.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com