Method for preparing polytriazole through catalysis of recyclable supported cuprous catalyst and prepared polytriazole

A copper catalyst, supported technology, applied in the field of polymer preparation, can solve problems such as the influence of photoelectric properties of polymers, and achieve the effects of improving photoelectric properties, increasing contact area, and high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0052] 1, Drying of A-21

[0053] Weigh 20g of wet commercially available A-21 resin (CAS No.: 9049-93-8), soaked in 100mL methanol for 0.5h, filtered, and repeated three times. The same method was used to wash three times with dichloromethane, and the obtained resin particles were dried overnight in a vacuum oven. Finally, light yellow spherical A-21 resin pellets.

[0054] 2. Preparation of supported click polymerization catalyst

[0055] Weigh 2.0g dry Add A-21 resin, 190mg CuI, into a 100mL single-necked bottle, add 30mL of degassed acetonitrile, and gently stir at room temperature for 17h under the protection of nitrogen. Acetonitrile was filtered off, followed by washing twice with 15 mL of acetonitrile and dichloromethane, and drying to obtain light green resin particles.

[0056] 3. Synthesis of azide and alkyne monomers

[0057] The synthesis methods of several first monomers and second monomers selected by the present invention are based on the applicant'...

Embodiment 1

[0061] The supported catalyst catalyzes the click polymerization of azide and alkyne to synthesize polymer P1:

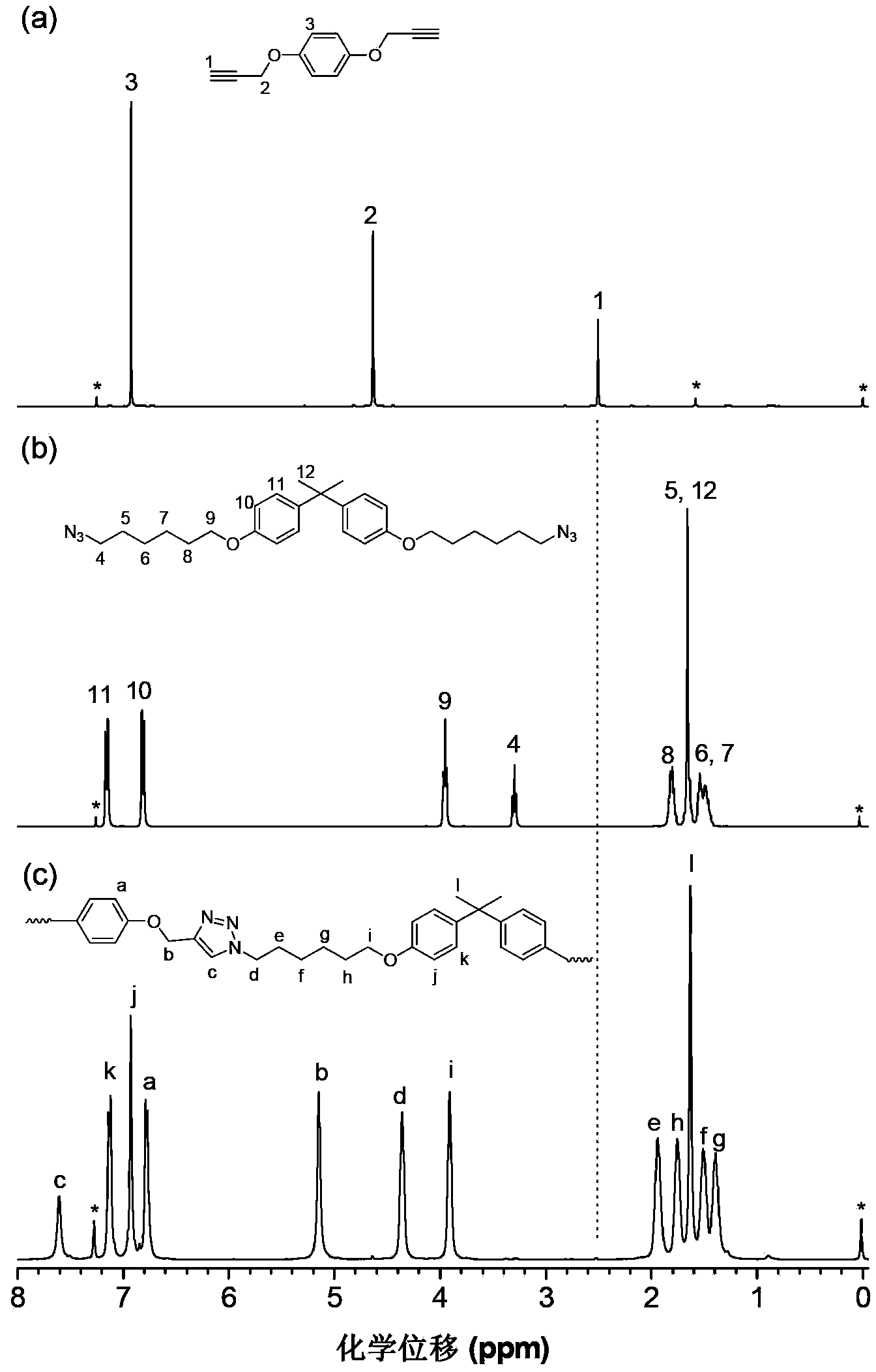

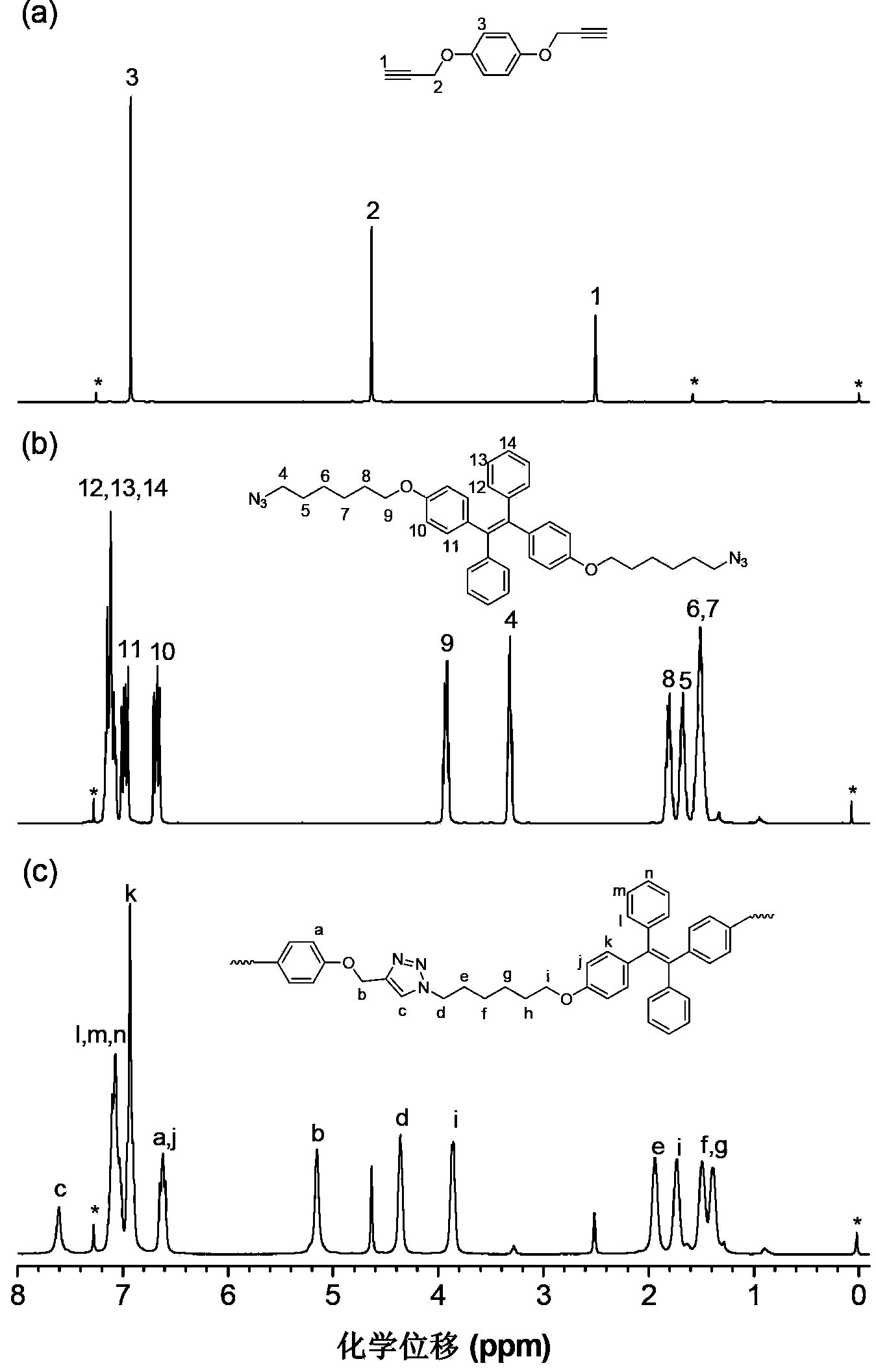

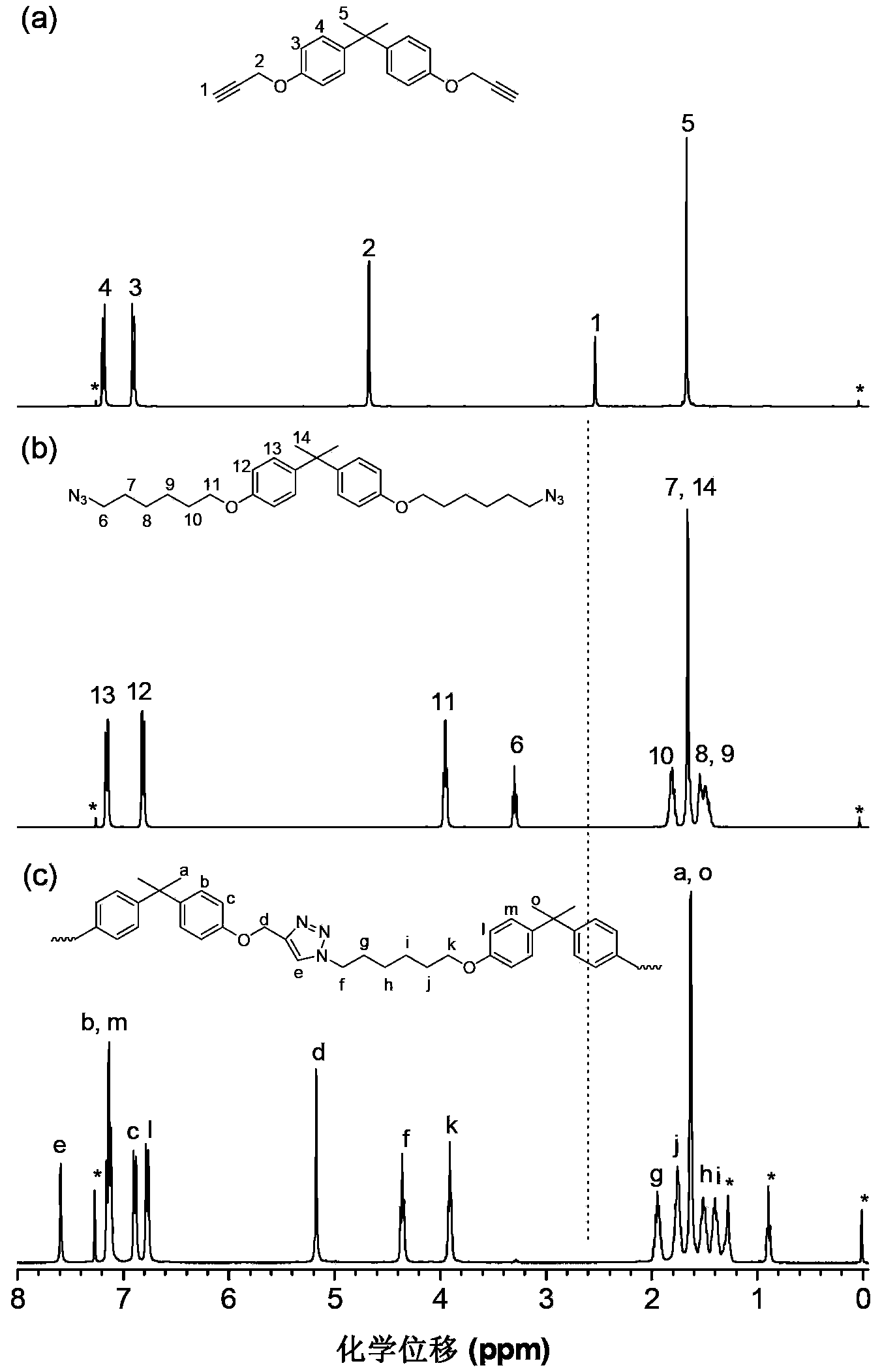

[0062] Alkyne monomer 1a (18.6 mg, 0.1 mmol), azide monomer 2a (47.9 mg, 0.1 mmol) and 15.0 mg CuIA-21 supported catalyst were added to a 10 mL polymerization tube. After evacuating and filling with nitrogen for 3 times, 1.0 mL of tetrahydrofuran was injected, and after the monomers were completely dissolved, the temperature was raised to 60°C for 8 hours of reaction. The reaction mother liquor was diluted with 5 mL of chloroform, filtered and added dropwise to 200 mL of rapidly stirring n-hexane to obtain a white flocculent precipitate. Stand overnight, filter, and dry to obtain 57.2 mg of polymer (yield: 86.1%) and copper content of 180 ppm. The weight average molecular weight was 45500, and the molecular weight distribution was 1.81. IR(KBr),ν(cm -1 ):2938,2094,1506,1232,829,575. 1 H NMR (400MHz, CDCl 3 ):δ(TMS,ppm):7.66,7.12,6.93,6.78,5.15,4.37,3.91,1.95,1....

Embodiment 2

[0068] CuI-Catalyzed Click Polymerization of Azides and Alkynes to Synthesize Polymer P1

[0069] Alkyne monomer 1a (18.6 mg, 0.1 mmol), azide monomer 2a (47.9 mg, 0.1 mmol) and 0.76 mg CuI were added to a 10 mL polymerization tube. After evacuating and filling with nitrogen for 3 times, inject 1.0 mL of N,N-dimethylformamide, and after the monomers are completely dissolved, raise the temperature to 60°C for 8 hours to react. The reaction mother liquor was diluted with 5 mL of chloroform, filtered and added dropwise into 200 mL of rapidly stirring n-hexane to obtain a brown flocculent precipitate. Stand overnight, filter and dry to obtain 52.5 mg of polymer (yield 79.0%) and copper content 4282 ppm. The weight average molecular weight was 33700, and the molecular weight distribution was 1.86. Other characterization results are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com