Methacrylic resin, preparation method thereof and photoresist

A technology of methacrylic acid and methyl methacrylate, applied in the chemical field, can solve the problems of long reaction time, small chain polymers, large amount of solvent synthesis effect, unsatisfactory and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

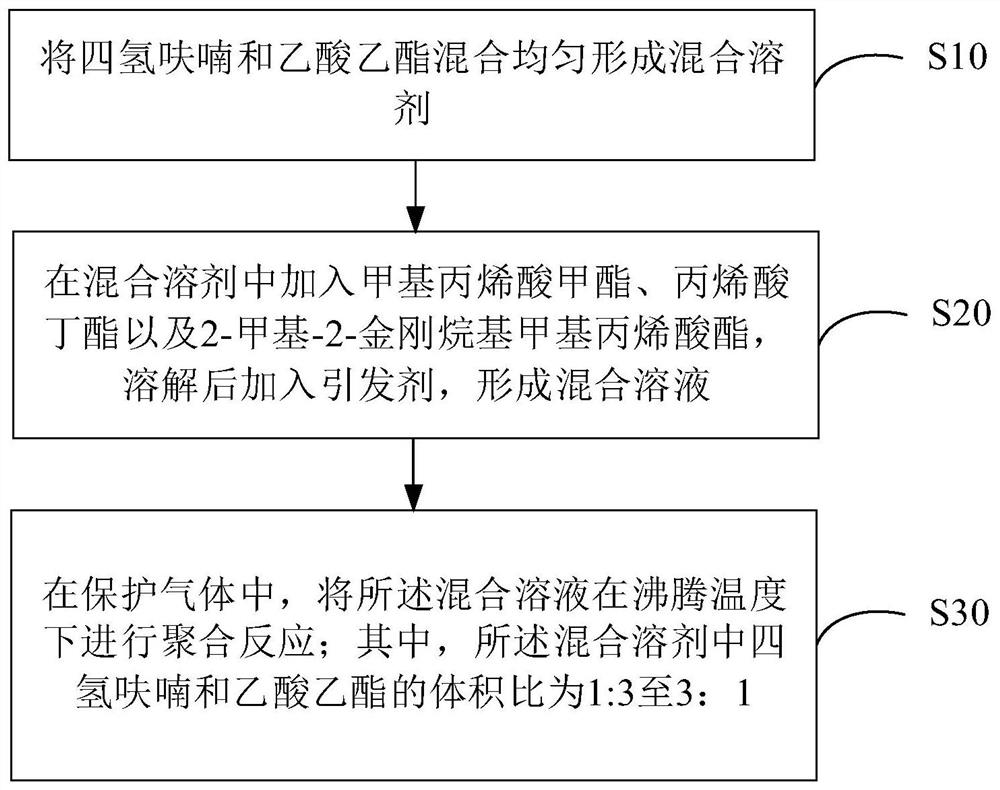

[0014] Such as figure 1 As shown, the embodiment of the present invention provides a method for preparing methacrylic resin. Described methacrylic resin preparation method comprises the steps:

[0015] Step S10, uniformly mixing tetrahydrofuran and ethyl acetate to form a mixed solvent;

[0016] Step S20, adding methyl methacrylate, butyl acrylate and 2-methyl-2-adamantyl methacrylate into the mixed solvent, adding an initiator after dissolving to form a mixed solution;

[0017] Step S30, in a protective gas, the mixed solution is subjected to a polymerization reaction at boiling temperature;

[0018] Wherein, the volume ratio of tetrahydrofuran and ethyl acetate in the mixed solvent is 1:3 to 3:1.

[0019] The traditional polymerization method of methacrylic resin is to add an initiator in the solution, heat and reflux in a water bath or an oil bath, and carry out free radical polymerization to control the molecular weight of the methacrylic resin. In order to achieve the...

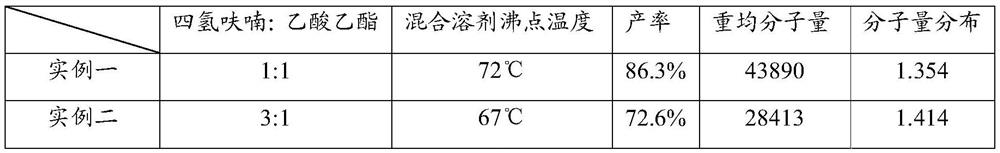

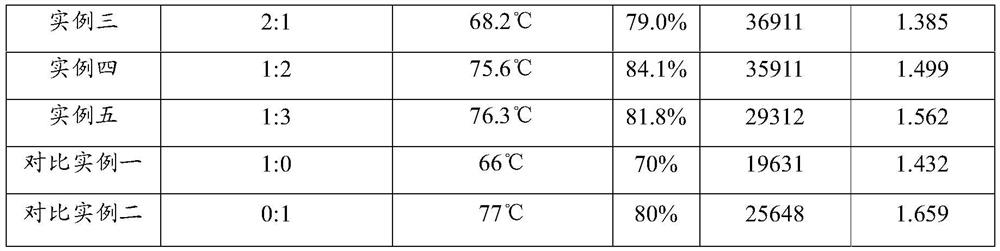

Embodiment 1

[0030] The invention provides a kind of mixed solvent method to carry out methacrylic resin polymerization, comprises the following steps:

[0031] (1) Put 1 part of tetrahydrofuran and 1 part of ethyl acetate in a four-necked flask, stir until they are evenly mixed, where the solvent is the volume ratio;

[0032] (2) 50g of methyl methacrylate, 30g of butyl acrylate and 20g of 2-methyl-2-adamantyl methacrylate are placed in a four-necked flask containing 300g of tetrahydrofuran-ethyl acetate mixed solvent , stir until the monomers are evenly mixed;

[0033] (3) After the monomer is dissolved, add benzoyl peroxide, stir until dissolved, and the dosage of benzoyl peroxide is 5 g;

[0034] (4) Place the four-necked flask equipped with the reaction solution in an oil bath equipped with a magnetic stirrer, install the condenser tube, and the nitrogen port, turn on the condensed water, feed nitrogen, turn on the stirring and raise the temperature To the boiling point of the mixed...

Embodiment 2

[0038] The invention provides a kind of mixed solvent method to carry out methacrylic resin polymerization, comprises the following steps:

[0039] (1) Put 3 parts of tetrahydrofuran and 1 part of ethyl acetate in a four-necked flask, stir until they are evenly mixed, where the solvent is the volume ratio;

[0040] (2) 50g of methyl methacrylate, 30g of butyl acrylate and 20g of 2-methyl-2-adamantyl methacrylate are placed in a four-necked flask containing 300g of tetrahydrofuran-ethyl acetate mixed solvent , stir until the monomers are evenly mixed;

[0041] (3) After the monomer is dissolved, add benzoyl peroxide, stir until dissolved, and the dosage of benzoyl peroxide is 5 g;

[0042] (4) Place the four-necked flask equipped with the reaction solution in an oil bath equipped with a magnetic stirrer, install the condenser tube, and the nitrogen port, turn on the condensed water, feed nitrogen, turn on the stirring and raise the temperature To the boiling point of the mixed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com