Synthetic method of lubricating fluid loss additive and application method thereof

A fluid loss reducing agent and a synthesis method technology, which are applied in the directions of drilling compositions, chemical instruments and methods, etc., can solve the problems of high salt, high maintenance and treatment cost of drilling fluid, high temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

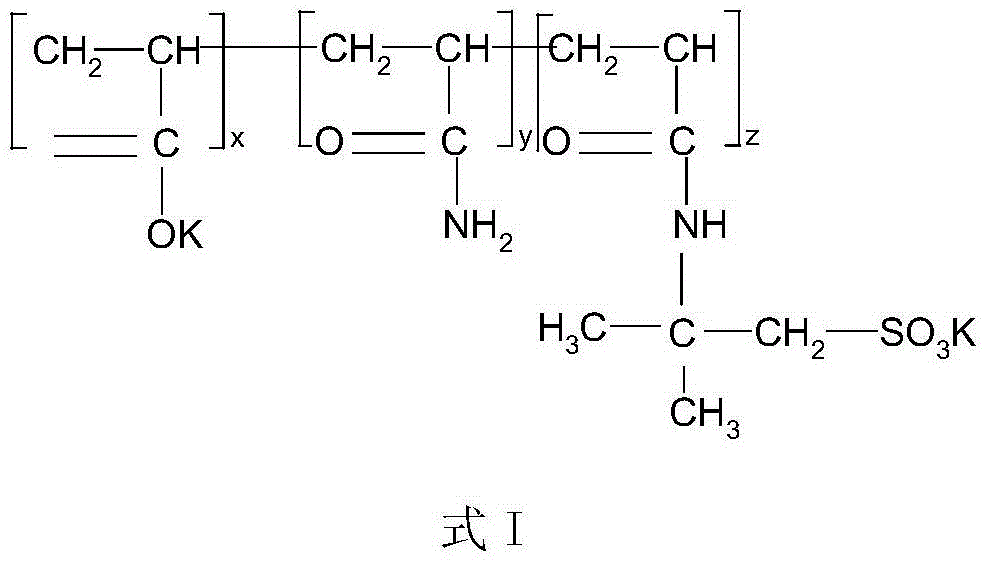

Image

Examples

Embodiment 1

[0023] Synthesis of lubricating fluid loss reducer:

[0024] In the aqueous solution of 100ml, add the acrylic acid (AA) of 30g to obtain 30% acrylic acid (AA) aqueous solution, the same method prepares 30% 2-acrylamido-2-methylpropanesulfonic acid (AMPS) aqueous solution and mix with 30% acrylamide (AM) aqueous solution.

[0025] 17.5mL of 30% acrylic acid (AA) aqueous solution was mixed with 17.5mL of 30% 2-acrylamido-2-methylpropanesulfonic acid (AMPS) aqueous solution, and the temperature of the solution was controlled at 10°C. Neutralize to pH=7 with KOH, add 35 mL of 30% acrylamide (AM) aqueous solution, and add 0.3 g of potassium persulfate.

[0026] Use white oil as the oil phase, put 30mL of white oil into a three-necked flask, add 3.5mL of SP-80, and stir for 20min. The above aqueous solution was slowly added dropwise to the three-necked flask, and the dropwise addition was completed within 10 minutes. During the dropwise addition process, keep stirring and blowin...

Embodiment 2

[0029] As described in Example 1, the difference is:

[0030] 10 mL of 30% acrylic acid (AA) aqueous solution was mixed with 10 mL of 30% 2-acrylamido-2-methylpropanesulfonic acid (AMPS) aqueous solution, and the solution temperature was controlled at 10°C. Neutralize to pH=7 with KOH, add 50 mL of 30% acrylamide (AM) aqueous solution, and add 0.3 g of potassium persulfate.

[0031] The dosage of lubricating fluid loss reducer is 0.3%, the API fluid loss is 13.6mL, and the lubrication coefficient is 0.35.

Embodiment 3

[0033] As described in Example 1, the difference is:

[0034] 15 mL of 30% acrylic acid (AA) aqueous solution was mixed with 15 mL of 30% 2-acrylamido-2-methylpropanesulfonic acid (AMPS) aqueous solution, and the solution temperature was controlled at 10°C. Neutralize to pH=7 with KOH, add 40 mL of 30% acrylamide (AM) aqueous solution, and add 0.3 g of potassium persulfate.

[0035] The dosage of lubricating fluid loss reducer is 0.3%, the API fluid loss is 13.2mL, and the lubrication coefficient is 0.29.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com