Polyurethane hot melt adhesive for high-grade lining cloth and preparation method thereof

A technology of polyurethane hot melt adhesive and polyurethane, which is applied in the direction of polyurea/polyurethane adhesive, adhesive, adhesive type, etc., can solve the problem of difficult bonding of interlining and fabric, and achieve not easy to change color and deterioration, good diffusion ability, The effect of high peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0064] Preparation of polyester polyol: Add ethylene glycol, 1,4-butanediol, 1,6-hexanediol in a molar ratio of 1:1:1 to adipic acid in an alkyd molar ratio of 1:1.25 Mixing, in the presence of the catalyst butyl titanate, at 140-220 DEG C, stepwise temperature rise reaction is adopted for 7-10 hours to carry out the alcoholysis reaction. During the reaction, the reaction system is protected with an inert gas to prevent the reaction liquid from turning yellow when exposed to oxygen, which will affect the color and appearance of the product. When the acid value of the mixture is lower than 25mg KOH / g, vacuumize, and continue the reaction under high vacuum (residual pressure≤100Pa) for 3 to 5 hours, and control until the alcoholysis reaction is complete. Carry out alcoholysis reaction at 140-220° C. for 7-10 hours, then vacuumize, and continue to react for 3-5 hours, thereby preparing polyester polyol.

Embodiment 1

[0066] Put 400g of polyester polyol and 50g of 1,4-butanediol in the reaction kettle in Preparation Example 1, heat to 120°C at 1.33KPa, dehydrate under reduced pressure for 30min under stirring, and then preheat to 305g of 4,4-diphenylmethane diisocyanate at 60°C was added, and 85g of toluene diisocyanate was added in 4 times within 2 hours under stirring, the reaction temperature was controlled at 110-115°C, and the reaction continued for 30 minutes after adding toluene diisocyanate , heat up to about 160°C, continue to stir for 30 minutes to form a prepolymer, then react with 150g of aromatic diamine chain extender C-1 to form polyurethane, add additives, and then grind and sieve under anaerobic conditions to obtain powder Polyurethane hot-melt adhesive for high-grade interlining, the number is SW-PU718.

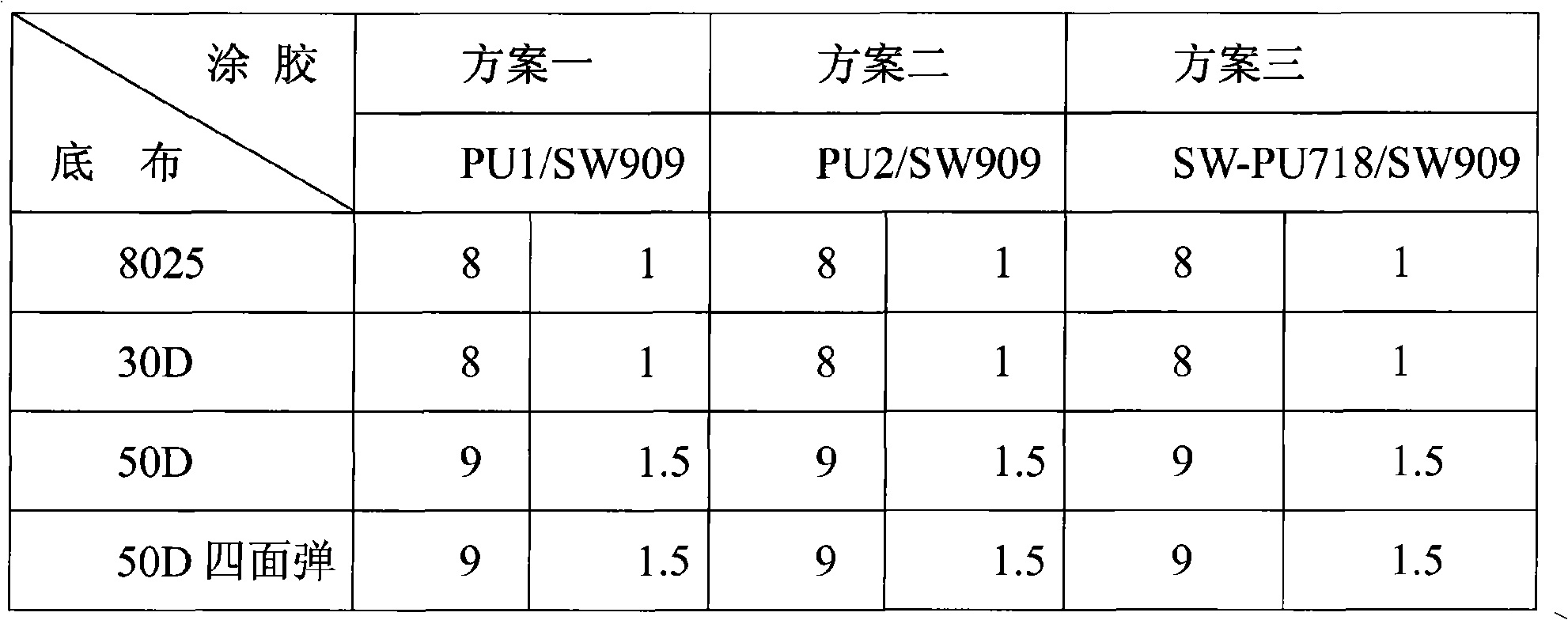

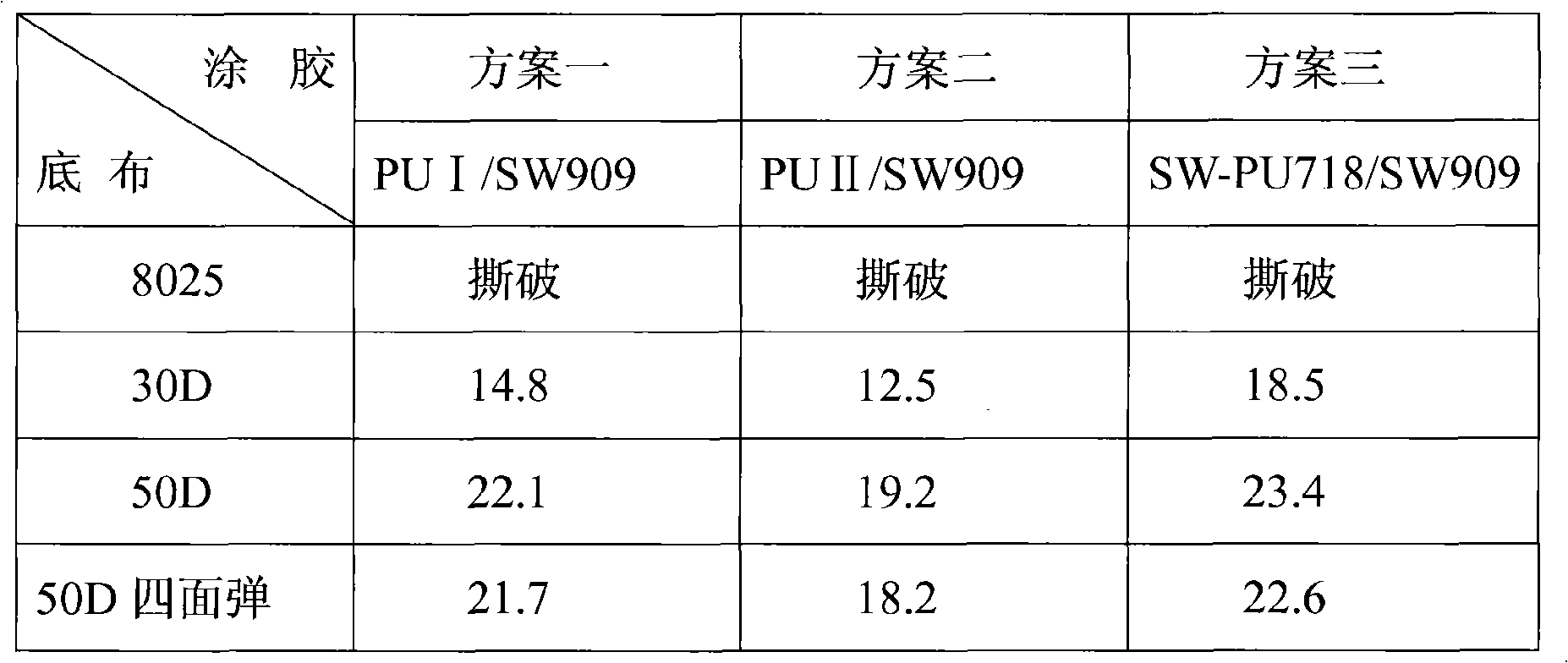

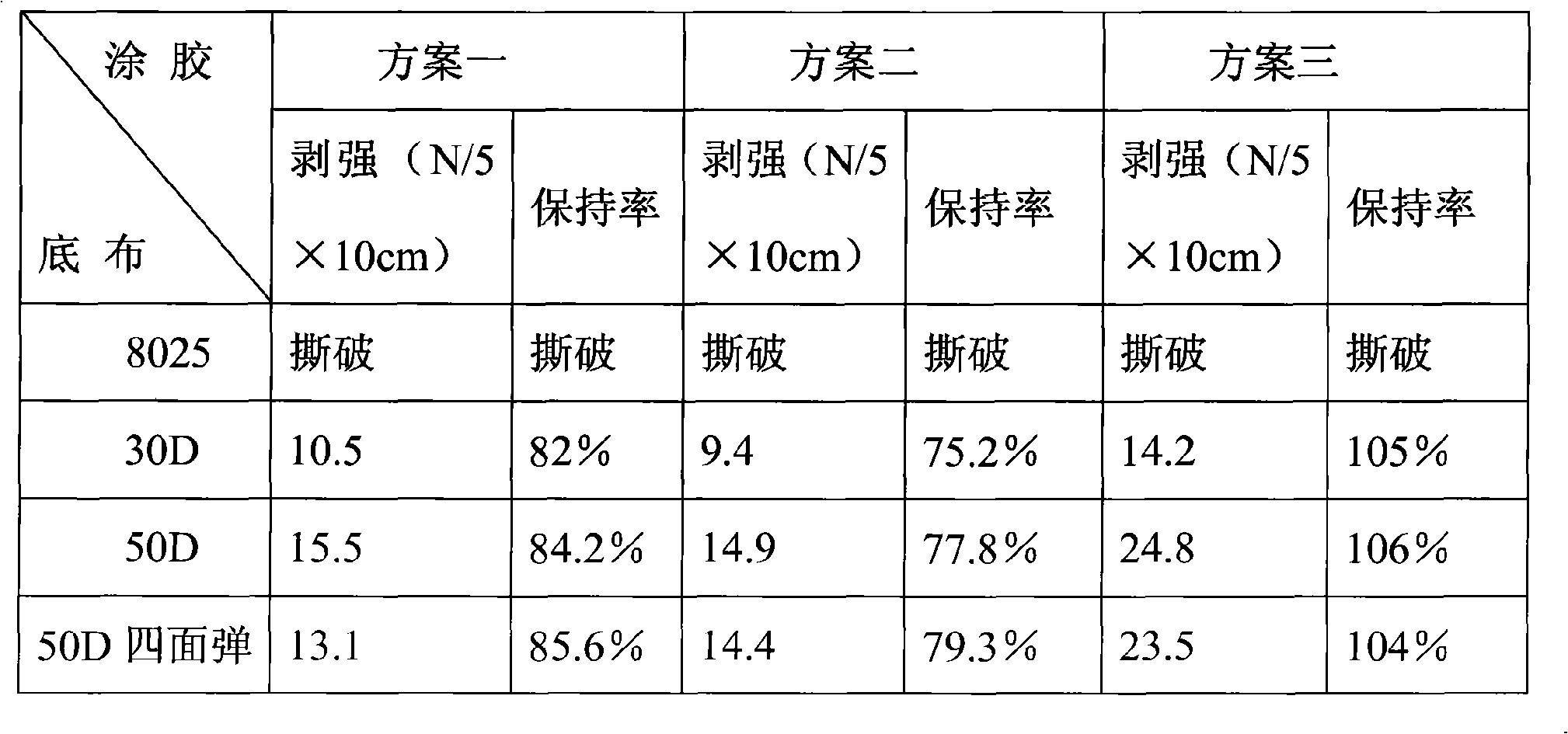

[0067] The application of the product of the present invention on various fabrics has done a lot of cross-contrast tests with polyamide hot melt adhesives at home and abr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com