Waste crosslinked polyethylene recovered material and recovery method thereof

A technology of cross-linked polyethylene and recycling methods, which is applied in the field of waste polymer recycling materials and its preparation, can solve the problems of difficult implementation and high equipment requirements, and achieve increased mechanical properties, excellent comprehensive properties, increased thermoplasticity and melt flow sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

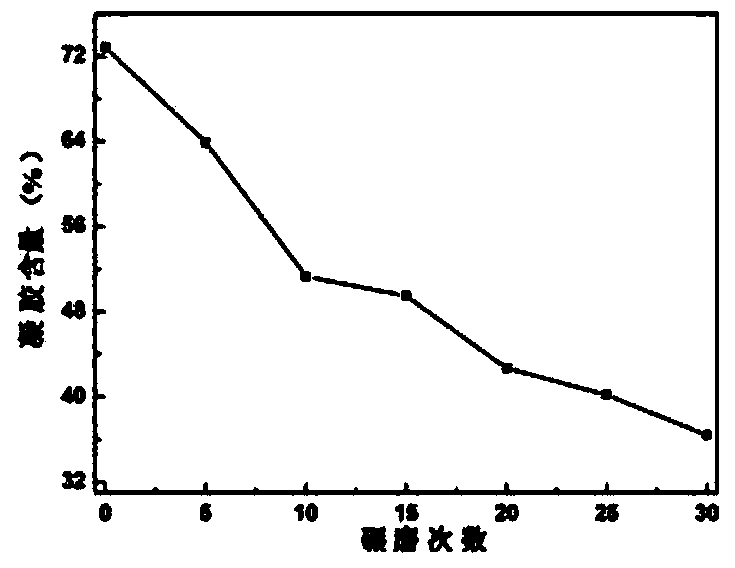

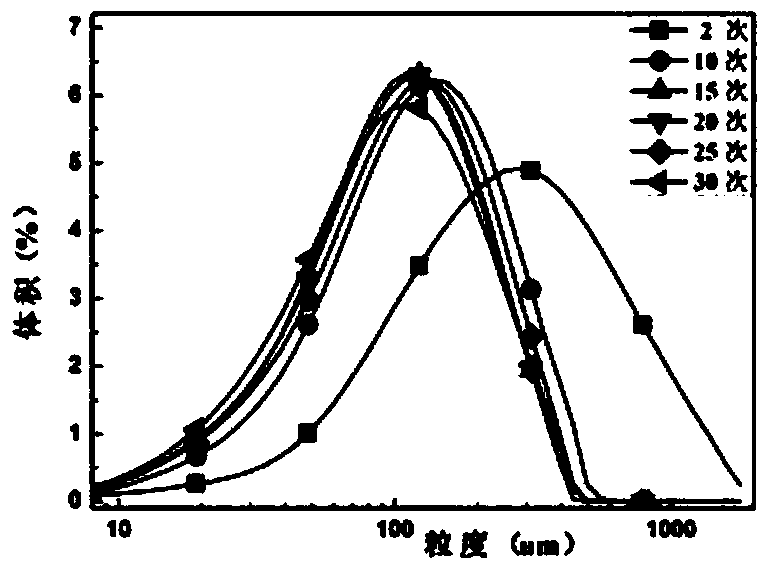

[0036] The waste peroxide cross-linked polyethylene pipes are mechanically crushed to 0.5-2cm particles, and then placed in a disc-type solid-phase force chemical reactor for grinding. During the grinding process, the cooling circulating water temperature is controlled at 5°C, and the grinding pressure is 50MPa. The grinding speed is 100 rpm, and the grinding is performed 30 times. The particle size of the obtained cross-linked polyethylene ultrafine powder is 500 mesh, and the gel content is 36.4%.

Embodiment 2

[0038] The waste silane cross-linked polyethylene cable material is mechanically crushed to 0.5-2cm particles, and then placed in a disc-type solid-phase force chemical reactor for grinding. During the grinding process, the cooling cycle water temperature is controlled at 30°C, and the grinding pressure is 10MPa. The milling speed is 1000rpm, and milling is performed 13 times. The obtained cross-linked polyethylene fine powder has a particle size of 290 mesh and a gel content of 52.4%.

Embodiment 3

[0040] The waste irradiated cross-linked polyethylene pipes are mechanically crushed to 0.5-2cm particles, and then placed in a disc-type solid-phase force chemical reactor for grinding. During the grinding process, the cooling cycle water temperature is controlled at 10°C, and the grinding pressure is 40MPa. The milling speed is 10 rpm, and milling is done 10 times. The obtained cross-linked polyethylene fine powder has a particle size of 320 mesh and a gel content of 50%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com