Biodegradable resin composition

A technology of biodegradable resins and compositions, applied in the field of polymer resin compositions, can solve the problems of slow degradation speed, affecting performance, easy aging, etc., and achieve the effects of accelerated degradation speed, good mechanical properties, and easy hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

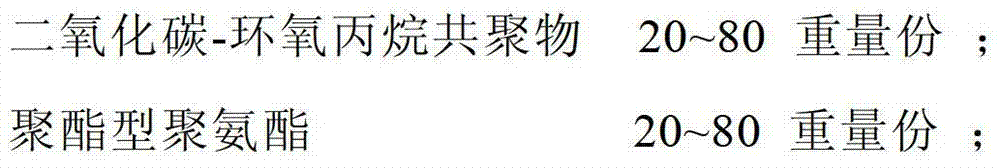

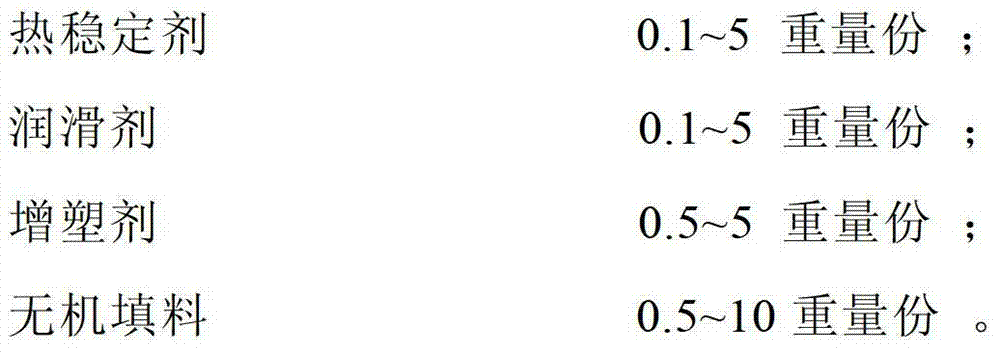

Method used

Image

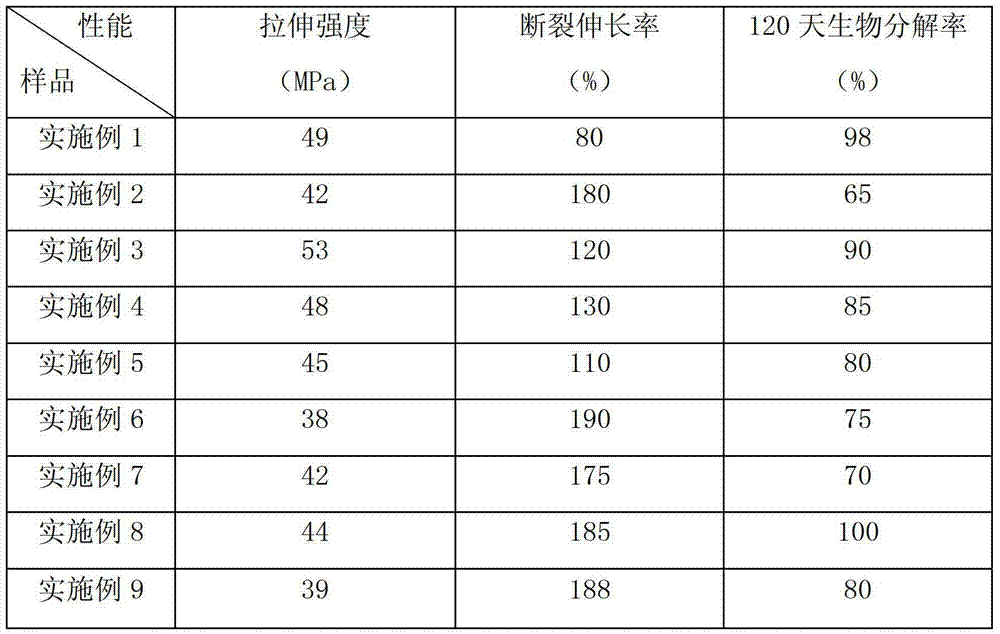

Examples

Embodiment 1

[0020] Example 1 , Preparation of biodegradable resin composition

[0021] 80g number average molecular weight is 40000 PPC, 20g polyester polyurethane, 1g carbodiimide, 5g monoglyceride stearate, 5g tributyl citrate and 10g white carbon black are placed in high-speed mixer with 1500r / The speed of min was blended for 5 minutes to obtain a mixture; then the mixture was placed in a vacuum oven, dried in vacuum at 45°C for 10 hours, then transferred to a Haake internal mixer, and banburyed at 180°C for 5 minutes at a speed of 30r / min to obtain biodegradable resin composition;

[0022] The above-mentioned polyester polyurethane is obtained by reacting polybutylene adipate and diisocyanate in the presence of a catalyst and a chain extender.

Embodiment 2

[0023] Example 2 , Preparation of biodegradable resin composition

[0024] 20g number average molecular weight is 60000 PPC, 80g polyester polyurethane, 5g maleic anhydride, 0.1g glyceryl tristearate, 0.5g macrogol 1000 and 0.5g calcium carbonate are placed in a high-speed mixer at 1500r Blended at a speed of 30r / min for 5min to obtain a mixture; then the mixture was placed in a vacuum oven, dried under vacuum at 45°C for 10h, then transferred to a Haake internal mixer, and internally kneaded at 190°C for 5min at a speed of 30r / min to obtain a bio degradable resin composition;

[0025] The above-mentioned polyester polyurethane is obtained by reacting polypropylene adipate and diisocyanate in the presence of a catalyst and a chain extender.

Embodiment 3

[0026] Example 3 , Preparation of biodegradable resin composition

[0027] 7000g number-average molecular weight is 80000 PPC, 3000g polyester polyurethane, 200g zinc stearate, 200g oleic acid amide, 50g epoxy soybean oil and 70g montmorillonite are placed in a high-speed mixer with a speed of 1500r / min Mix for 8 minutes to obtain a mixture; then place the mixture in a vacuum oven, dry it in vacuum at 45°C for 10 hours, then transfer it to a twin-screw extruder with an aspect ratio of 35, extrude and granulate at a speed of 100r / min to obtain biodegradable resin composition;

[0028] The above-mentioned polyester polyurethane is obtained by reacting polyethylene adipate and diisocyanate in the presence of a catalyst and a chain extender.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com