Green biodegradable plastic film and processing technology thereof

A technology of biodegradation and plastic film, applied in the field of plastic film, can solve the problems of difficult to ensure the fixed conditions of plastic film degradation, processing performance, mechanical properties and poor thermoplasticity, etc., to improve mechanical properties, excellent strength, and improve polymer properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

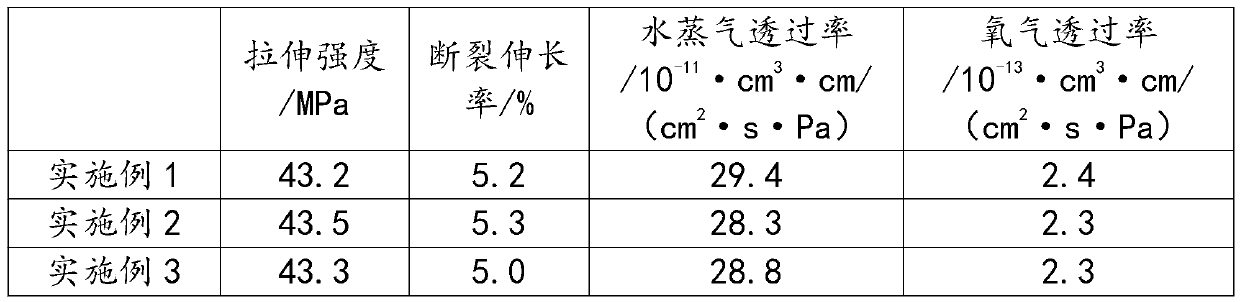

Examples

Embodiment 1

[0050] The green biodegradable plastic film is made of the following raw materials in parts by weight: 60-70 parts of polyadipate / butylene terephthalate (PBAT), 20-30 parts of polylactic acid (PLA), modified starch 16-24 parts, 4-7 parts of reinforcing filler, 5-8 parts of glycerin, ethylene glycol, propylene glycol, stearic acid amide, methylene bis-stearamide, 2-3 parts of ethylene bis-stearamide, hindered amines 1-2 parts of light stabilizer;

[0051] Described green biodegradable plastic film is made by following steps:

[0052] Step S1, drying poly(butylene adipate / terephthalate), polylactic acid, modified starch and reinforcing filler in a vacuum oven at 60°C, 45°C, 40°C and 80°C for 6 hours, respectively;

[0053] Step S2, adding the dried polybutylene adipate / terephthalate, polylactic acid, modified starch and reinforcing filler into the twin-screw extruder at the same time, and then adding plasticizer, lubricant and light stabilizer, Melt blending, the blend is extr...

Embodiment 2

[0057] The green biodegradable plastic film is made of the following raw materials in parts by weight: 60-70 parts of polyadipate / butylene terephthalate (PBAT), 20-30 parts of polylactic acid (PLA), modified starch 16-24 parts, 4-7 parts of reinforcing filler, 5-8 parts of glycerin, ethylene glycol, propylene glycol, stearic acid amide, methylene bis-stearamide, 2-3 parts of ethylene bis-stearamide, hindered amines 1-2 parts of light stabilizer;

[0058] Described green biodegradable plastic film is made by following steps:

[0059] Step S1, drying poly(butylene adipate / terephthalate), polylactic acid, modified starch and reinforcing filler in a vacuum oven at 60°C, 45°C, 40°C and 80°C for 6 hours, respectively;

[0060] Step S2, adding the dried polybutylene adipate / terephthalate, polylactic acid, modified starch and reinforcing filler into the twin-screw extruder at the same time, and then adding plasticizer, lubricant and light stabilizer, Melt blending, the blend is extr...

Embodiment 3

[0064] A green biodegradable plastic film is made of the following raw materials in parts by weight: 70 parts of polyadipate / butylene terephthalate (PBAT), 30 parts of polylactic acid (PLA), 24 parts of modified starch, reinforced 7 parts of filler, 8 parts of propylene glycol, 3 parts of ethylene bisstearamide, 2 parts of hindered amine light stabilizer;

[0065] Described green biodegradable plastic film is made by following steps:

[0066] Step S1, drying poly(butylene adipate / terephthalate), polylactic acid, modified starch and reinforcing filler in a vacuum oven at 60°C, 45°C, 40°C and 80°C for 6 hours, respectively;

[0067] Step S2, adding the dried polybutylene adipate / terephthalate, polylactic acid, modified starch and reinforcing filler into the twin-screw extruder at the same time, and then adding plasticizer, lubricant and light stabilizer, Melt blending, the blend is extruded and granulated by a twin-screw extruder to obtain plastics;

[0068] Step S3, vacuumize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com