Biodegradable plastic color master batch and making method thereof

A degradable plastic, all-biological technology, applied in the field of plastics, can solve the problems of mixing full-biodegradable plastics with non-degradable plastic components, material performance decline, affecting the degradation rate, etc., to avoid time-consuming, labor-intensive and physical properties. , the effect of high concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

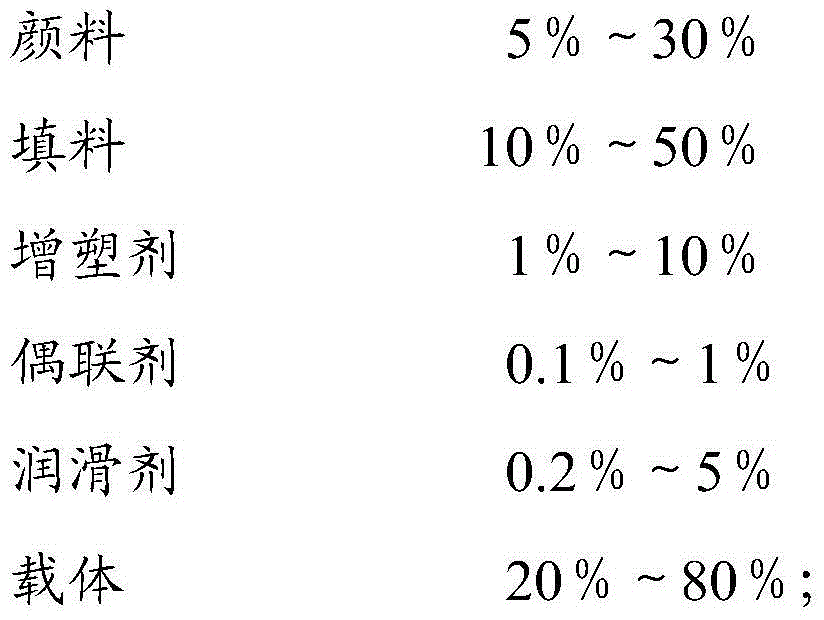

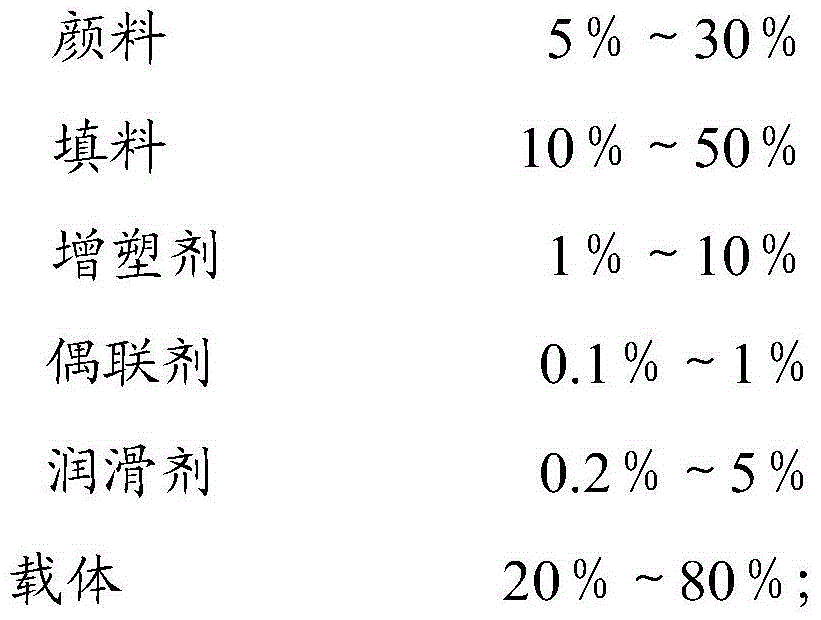

Method used

Image

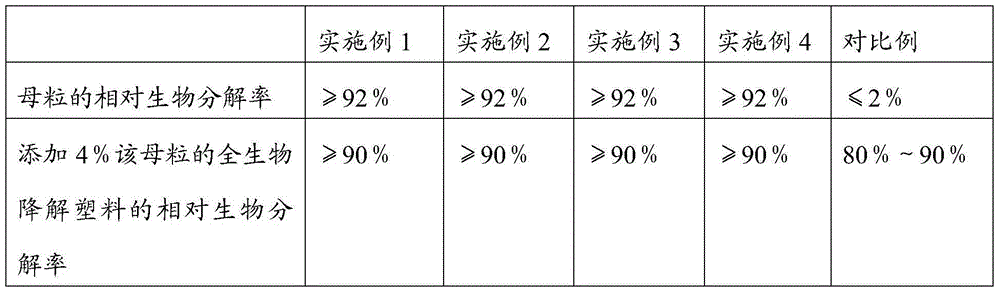

Examples

Embodiment 1

[0049] A fully biodegradable plastic color masterbatch, comprising 30% of pigment, 10% of protein powder, 10% of urea, 0.1% of aluminate, 4.9% of erucamide and 45% of PHB calculated by weight percentage.

[0050] Preparation:

[0051] Step A. put the amount of pigment and protein powder into the reactor, and stir at a high speed at 100°C-110°C for 10-30 minutes to remove the moisture therein;

[0052] Step B. Add the urea into the reactor, mix at high speed for 5-15 minutes, let the protein powder soften and disorder;

[0053] Step C. Then add aluminate and mix at high speed for 5-15 minutes, so that the pigment and protein powder become hydrophobic;

[0054] Step D. Finally, add erucamide and PHB, mix at high speed for 1-5 minutes, and obtain a mixture after discharging.

[0055] Step E. Melt and blend the mixture through a twin-screw extruder, extrude and granulate, cool and dry to obtain the fully biodegradable plastic masterbatch. The temperature zones of the extruder a...

Embodiment 2

[0057] A fully biodegradable plastic color masterbatch, including 5% of pigment, 50% of starch, 1% of ethylene glycol, 1% of silane coupling agent, 0.2% of stearic acid and 42.8% of PLA calculated by weight percentage;

[0058] The preparation method is the same as in specific example 1.

Embodiment 3

[0060] A fully biodegradable plastic masterbatch, including 25% pigment, 45% protein powder, 7% glycerin, 0.5% aluminate, 2.5% oleic acid amide and 20% PBS calculated by weight percentage;

[0061] The preparation method is the same as in specific example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com