Biodegradable supertough polylactic acid (PLA) blend material and preparation method thereof

A polylactic acid and blend technology, which is applied in the field of polymer mixture materials, can solve the problems of poor ductility and poor toughness, and achieves improved elongation at break, improved elongation at break and impact strength, and excellent impact resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

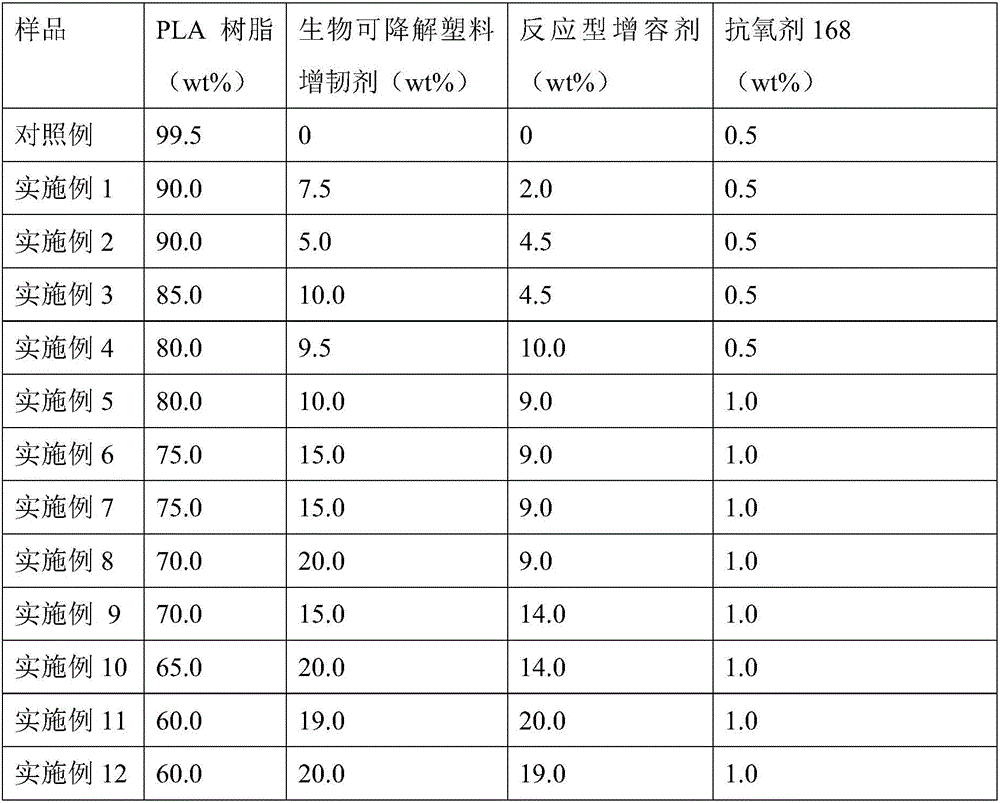

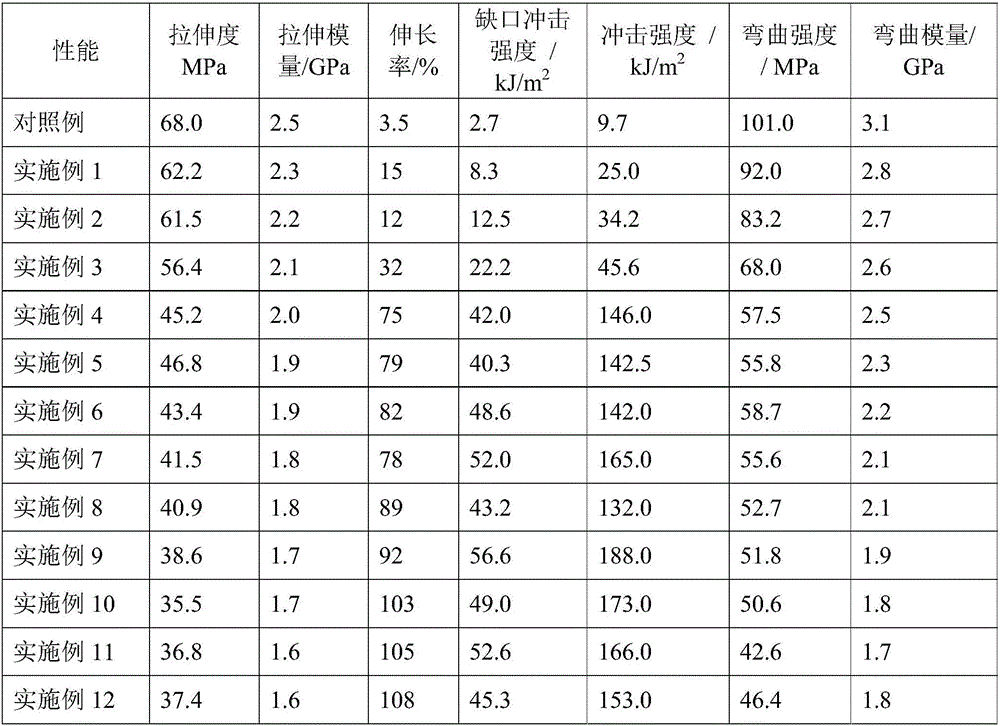

Embodiment 1

[0017] 90.0wt% polylactic acid resin, 7.5wt% polybutylene succinate, 2.0wt% polybutyl methacrylate-glycidyl methacrylate copolymer, 0.5wt% antioxidant triphosphite (2,4-di-tert-butylphenyl) ester (168) was mixed in a high-speed mixer, added to a Hakke internal mixer, melted and blended at 170-200 ° C, the speed was 100 rpm, and the mixing time was 5 minutes, and then The melt is extruded through a twin-screw extruder at a speed of 50 rpm, and the temperature of each section is 180-200° C., and cooled to granulate. A standard sample of the biodegradable super-tough polylactic acid ternary blend was prepared by compression molding or injection molding, and its mechanical and mechanical properties were measured. The tensile strength is 62.2MPa, the elongation at break is 15%, the notched impact strength is 8.3MPa, the unnotched impact strength is 25.0MPa, and the bending strength is 92.0MPa.

Embodiment 2

[0019] 90.0wt% polylactic acid resin, 5.0wt% polyadipate / butylene terephthalate (PBAT), 4.5wt% ethylene-acrylate-glycidyl methacrylate terpolymer and 0.5wt% %Antioxidant 168 was mixed in a high-speed mixer, added to a Hakke internal mixer, melted and blended at 170-200 ° C, the speed was 100 rpm, and the mixing time was 10 minutes, and then the melt was melted and extruded through a twin-screw extruder , the rotation speed is 50rpm, the temperature of each section is 180-200°C, and it is cooled and granulated. A standard sample of the biodegradable super-tough polylactic acid ternary blend was prepared by compression molding or injection molding, and its mechanical and mechanical properties were measured. The tensile strength of the modified PLA material is 61.5MPa, the elongation at break is 12%, the notched impact strength is 12.5MPa, the unnotched impact strength is 34.2MPa, and the bending strength is 83.2MPa.

Embodiment 3

[0021] Put 85.0wt% polylactic acid resin, 10.0wt% polybutylene succinate, 4.5wt% polybutyl methacrylate-glycidyl methacrylate copolymer, 0.5wt% antioxidant 168 into Mix in a high-speed mixer, add it to a Hakke internal mixer, melt and blend at 170-200°C, the speed is 100rpm, and the mixing time is 8min, and then the melt is melted and extruded through a twin-screw extruder with a speed of 50rpm 180-200 ° C, and cooling granulation. A standard sample of the biodegradable super-tough polylactic acid ternary blend was prepared by compression molding or injection molding, and its mechanical and mechanical properties were measured. The tensile strength of the modified PLA material is 56.4MPa, the elongation at break is 32%, the notched impact strength is 22.2MPa, the unnotched impact strength is 45.6MPa, and the bending strength is 68.0MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Notched impact strength | aaaaa | aaaaa |

| Unnotched impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com