Full-biodegradable plastic film and preparation method thereof

A plastic film, all-biological technology, applied in the field of full biodegradable plastic film and its preparation, can solve the problems of limited application range of full biodegradable plastic film, limited product use temperature, low tear strength, etc., and achieve excellent biodegradation. The effect of performance, wide operating temperature range and high tear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

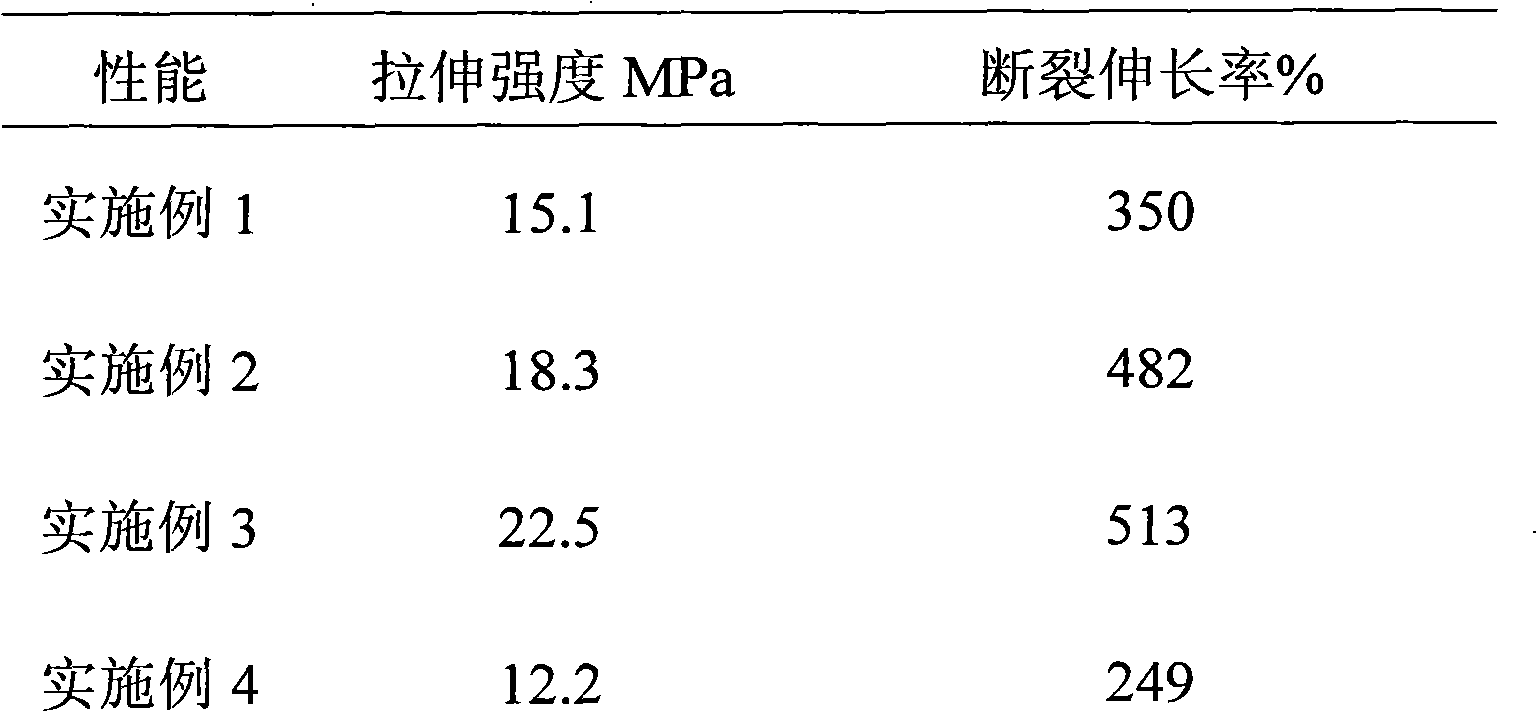

[0029] 35 parts by weight of polyethylene carbonate polyurethane, 17.5 parts by weight of thermoplastic cornstarch, 5.6 parts by weight of octadecenoic acid, 3.5 parts by weight of calcium carbonate, 2 parts by weight of glycerin, 10 parts by weight of stearic acid amide and polystyrene with a molecular weight of 1000 15.4 parts by weight of ethylene carbonate diol were mixed evenly, and the single-screw extruder was used to carry out melt extrusion granulation, and the temperature of the granulation was 220°C; then the film blowing machine with an aspect ratio of 30 was used to blow the film, A fully biodegradable plastic film is obtained.

[0030] The mechanical properties of the obtained fully biodegradable plastic film were tested according to the method of GB / T4456-1996, and the results are shown in Table 1.

Embodiment 2

[0032] 45.5 parts by weight of polyethylene carbonate polyurethane, 7 parts by weight of thermoplastic tapioca starch, 5.6 parts by weight of dodecenyl succinic anhydride, 3.5 parts by weight of clay, 5 parts by weight of bis-(2-ethylhexyl) adipate Mix evenly with 30 parts by weight of methylene bis stearamide, carry out melt extrusion granulation with a single-screw extruder, the temperature of the granulation is 205 ° C; then use a film blowing machine with an aspect ratio of 30 to blow the film , to obtain a fully biodegradable plastic film.

[0033] The mechanical properties of the obtained fully biodegradable plastic film were tested according to the method of GB / T4456-1996, and the results are shown in Table 1.

Embodiment 3

[0035] Get 49 parts by weight of polyethylene carbonate polyurethane, 3.5 parts by weight of thermoplastic pea starch, 5.6 parts by weight of undecenyl succinic anhydride, 3.5 parts by weight of montmorillonite, 5 parts by weight of ethylene glycol, 5 parts by weight of propylene glycol and ethylene glycol 10 parts by weight of bis stearamide, mixed evenly, melt extrusion granulation with a single-screw extruder, the granulation temperature is 230 ° C; then blow the film with a film blowing machine with an aspect ratio of 30 to obtain a fully biodegradable plastic film.

[0036] The mechanical properties of the obtained fully biodegradable plastic film were tested according to the method of GB / T4456-1996, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com