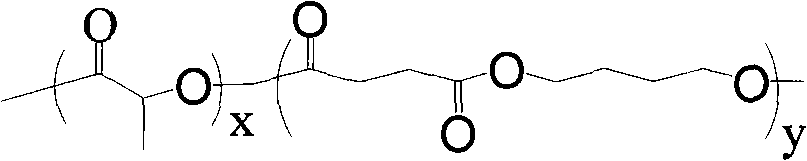

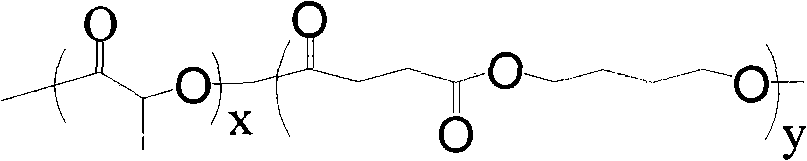

Biodegradable copolymer and preparation method thereof

A technology of biodegradation and copolymer, applied in the preparation of the copolymer, in the field of polybutylene succinate-polylactic acid copolymer, can solve the problems of poor processing stability, limited wide application, poor impact resistance, etc. The effect of improving toughness, reducing cost and good physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

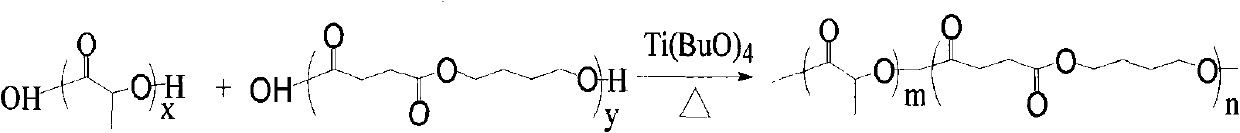

Method used

Image

Examples

Embodiment 1

[0041] Take by weighing the polybutylene succinate oligomer (M n =0.52×10 4 g / mol, M W / M N =1.42) and the polylactic acid oligomer (M n =0.47×10 4 g / mol, M W / M N =2.87), put it into a 1L polyester reaction kettle, add 0.25g of tetrabutyl titanate, replace the air in the reaction kettle with nitrogen for 3 times, control the stirring rate at 60rpm, program the temperature to 190°C, and turn on the vacuum pump to ensure the system The vacuum degree is within 100 Pa, and after reacting under vacuum conditions for 5 hours, the prepared product is extruded with nitrogen gas, and pelletized to obtain a PBS-co-PLA copolymer.

[0042] The crude product of PBS-co-PLA copolymer was dissolved in chloroform, and reprecipitated with a large amount of cold methanol, repeated 2 to 3 times, and finally the product was dried in a vacuum oven at 40°C for 24 hours.

Embodiment 2

[0044] The experimental process and conditions are the same as those in Example 1, the amount of PBS oligomer used is 200g, and the amount of polylactic acid oligomer used is 100g.

Embodiment 3

[0046]The experimental process and conditions are the same as in Example 1, the amount of PBS oligomer used is 200g, and the amount of polylactic acid oligomer used is 25g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com