Biodegradable copolymer

A copolymer and biological technology, applied in the field of materials, can solve problems such as insufficient flexibility, reduce costs, simplify the solution refining process, and facilitate industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of the biodegradable copolymer that the present invention proposes, concrete steps are as follows:

[0026] (1) Place polyhydroxy acid or polyamino acid and polyol, polyacid or polyamine in a vacuum reactor, and direct polycondensation reaction occurs under the action of a catalyst. First react at a vacuum of 1-2KPa and a temperature of 80-120°C for 3-5 hours, then vacuumize to control the vacuum below 100Pa, and continue to react for 3-25 hours at a temperature of 130-180°C. Obtain copolymer prepolymer;

[0027] (2) the copolymer prepolymer obtained in the step (1) is placed in the reactor, and the vacuum degree is below 100Pa, under N 2 In the atmosphere, the copolymer undergoes polymerization reaction under the action of the coupling agent, the polymerization temperature is 150-230 DEG C, and the polymerization reaction time is 10-300 minutes to obtain the desired product.

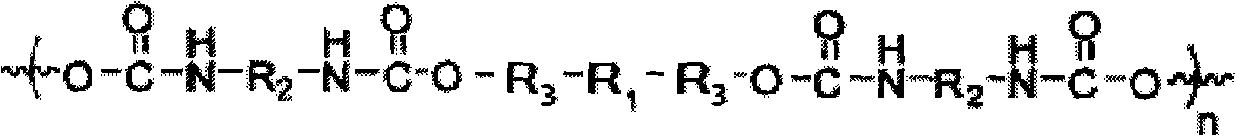

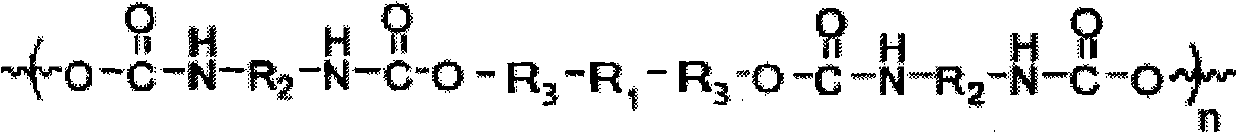

[0028] By adjusting R 1 , R 2 , R 3 The amount of biodegradable c...

Embodiment 1

[0030] Copolymer component: R1=polyethylene glycol;

[0031] R2=C 13 h 10 ;

[0032] R3 = L-polylactic acid.

[0033]

[0034]

Embodiment 2-3

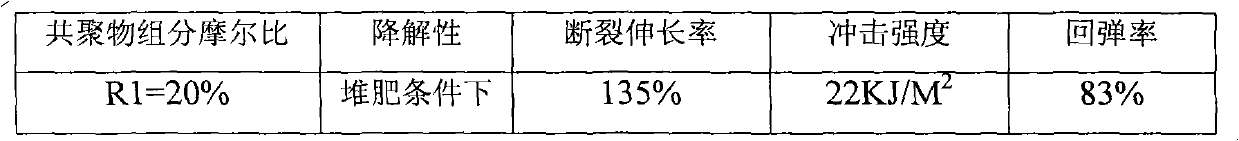

[0035] Embodiment 2-3: On the basis of embodiment 1, change R1, R2, the component ratio of R3, the result is as follows:

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com