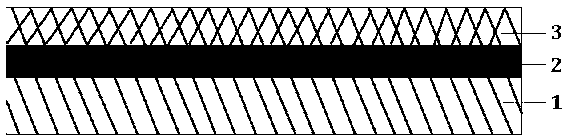

Composite wear-resistant liner of sandwich structure

A wear-resistant liner, liner technology, applied in the direction of layered products, chemical instruments and methods, metal layered products, etc., can solve the problem of pure polyurethane sheet tearing grinding efficiency, limited temperature and aging resistance, line The problem of large difference in expansion coefficient can achieve the effect of avoiding heat treatment process, high wear resistance and excellent bonding performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

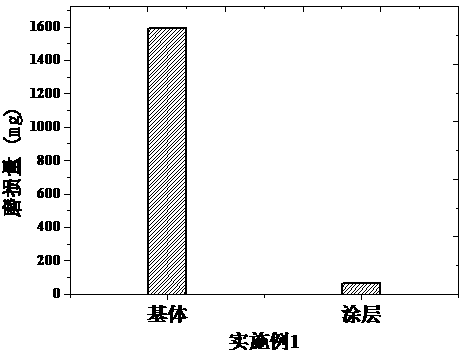

Embodiment 1

[0026] Take Q550 steel for cutting, cold-press to form the desired liner shape, and blast the surface; adjust the ratio of adhesive to Ni-15 powder to 1:20, adjust it to a viscous state with alcohol, apply it to the surface of the sample, and place it on the resistance Dry in an oven at 150 °C for 1 h. First, use an oxygen-acetylene flame to preheat the sample to 780 ° C ~ 820 ° C; then carry out flame remelting, use an oxygen-acetylene flame neutral partial carbon flame to remelt the above sample, and the distance between the spray gun and the surface of the workpiece is about 25~ 30 mm, at an angle of 75° to the plane of the sample, the remelting gun travel speed is 120~140mm / min, the oxygen pressure is 0.30MPa, and the acetylene pressure is 0.10MPa; when the surface appears / mirror reflection, air cooling. Then use the same process as above to coat with Ni-60 and WC-17%Co (ratio of 4:1), and the thickness of the coating after two remelting is about 1.2~1.6mm.

[0027] The d...

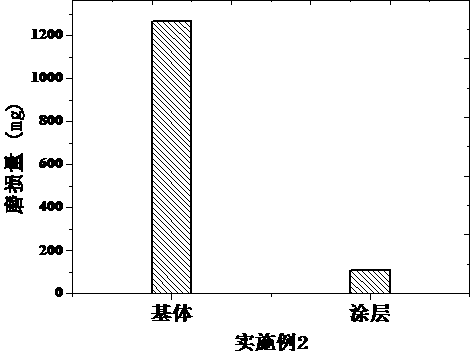

Embodiment 2

[0029] Take Q235 steel for cutting, cold pressing to form the desired liner shape, and sandblasting the surface; the ratio of adhesive to F-103 powder is 1:20, adjusted to a viscous state with alcohol, coated on the surface of the sample, placed on the resistance Dry in an oven at 150 °C for 1 h. First, use an oxygen-acetylene flame to preheat the sample to 780 °C ~ 820 °C; then carry out flame remelting, and use an oxygen-acetylene flame to remelt the above sample with a neutral flame. The distance between the spray gun and the workpiece surface is about 25~30 mm , at an angle of 75° to the sample plane, the remelting gun travel speed is 100~120mm / min, the oxygen pressure is 0.30MPa, and the acetylene pressure is 0.06MPa; when the surface appears / mirror reflection, air cooling. Then use the same process as above to coat with Fe-65 and WC-20%Ni (the ratio is 4:1), and the thickness of the coating after two remelting is about 0.9~1.2mm.

[0030] The dry friction and wear prope...

Embodiment 3

[0032] Take 1025 steel for cutting, cold-press to form the desired liner shape, and blast the surface; adjust the ratio of adhesive to F-101 powder to 1:25, adjust it to a viscous state with alcohol, apply it to the surface of the sample, and place it on the resistance Dry in an oven at 150 °C for 1 h. First, use an oxygen-acetylene flame to preheat the sample to 780 °C ~ 820 °C; then carry out flame remelting, and use an oxygen-acetylene flame to remelt the above sample with a neutral flame. The distance between the spray gun and the surface of the workpiece is about 25~30 mm. , at an angle of 75o to the sample plane, the remelting gun travel speed is 80~100mm / min, the oxygen pressure is 0.30MPa, and the acetylene pressure is 0.08MPa; when the surface appears / mirror reflection, air cooling. Then use the same process as above to coat with Ni-21 and WC-20%Ni (the ratio is 4:1), and the thickness of the coating after two remelting is about 1.2~1.5mm.

[0033]The dry friction an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com