Device for preparing special-shaped metal-based porous composite material

A composite material and special-shaped metal technology, applied in metal processing equipment, casting molds, cores, etc., can solve the problems of waste of metal raw materials, insufficient seepage, difficult operation, etc., to avoid crystallization looseness and shrinkage cavity, and improve production efficiency , Improve the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

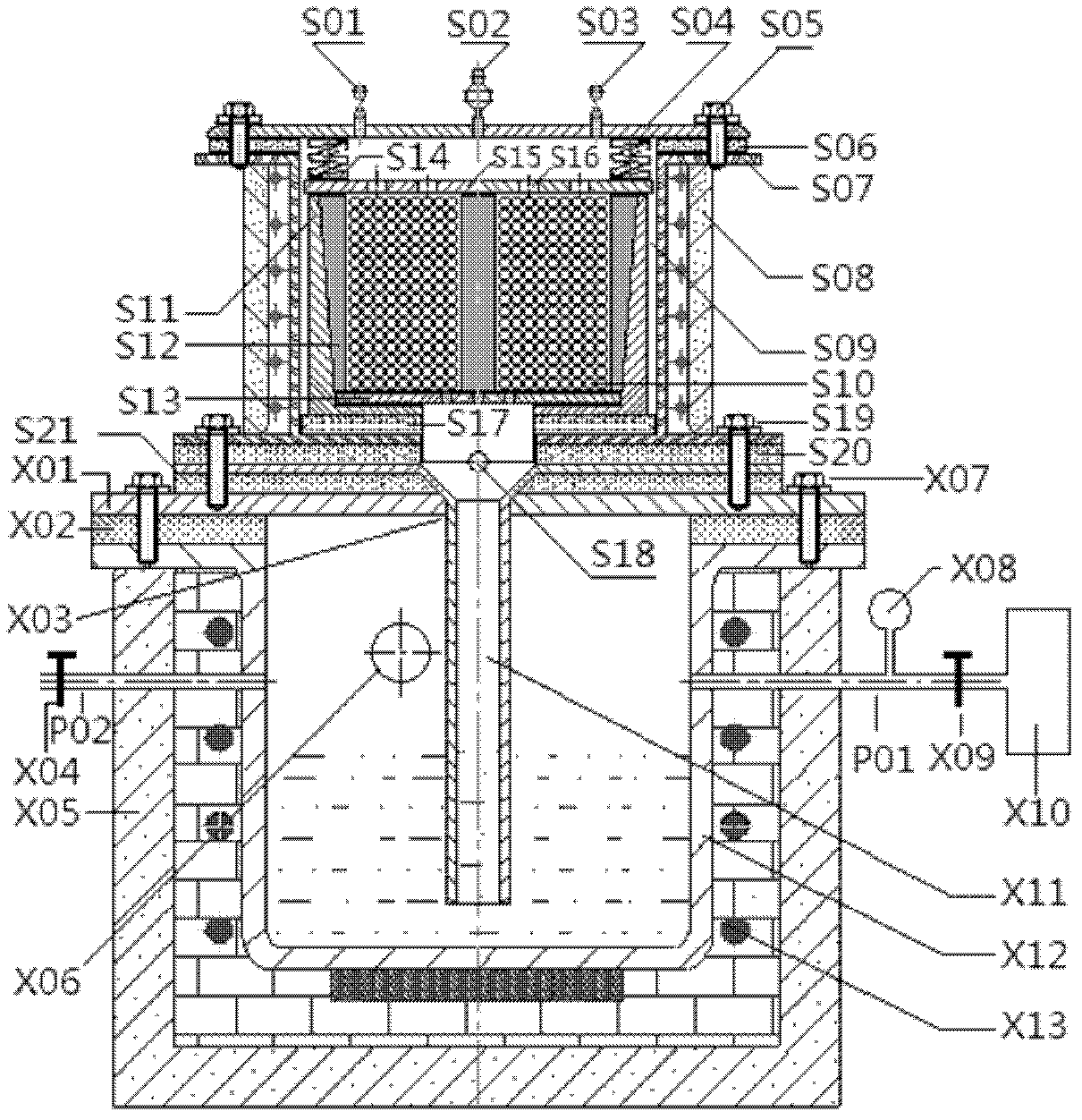

[0032] The device of the present invention is used to prepare a sandwich structure sandwich panel.

[0033]The sandwich structure sandwich panel described in this embodiment refers to the LY12 panel whose panel material is 1.26mm thick, the core material is aluminum / alumina hollow sphere composite material, and the particle size of the alumina hollow spheres used is 1.6-2.0mm , using 6063 aluminum alloy as the aluminum in the core material. attached figure 2 Schematic of the equipment used to prepare the materials for this example. The specific implementation of this embodiment includes the following steps:

[0034] (1) Grind the surface of the aluminum panel S12 with coarse sandpaper to remove the scale, and use a coarse steel wire wheel to grind out irregular lines with a depth of 0.1-0.3mm;

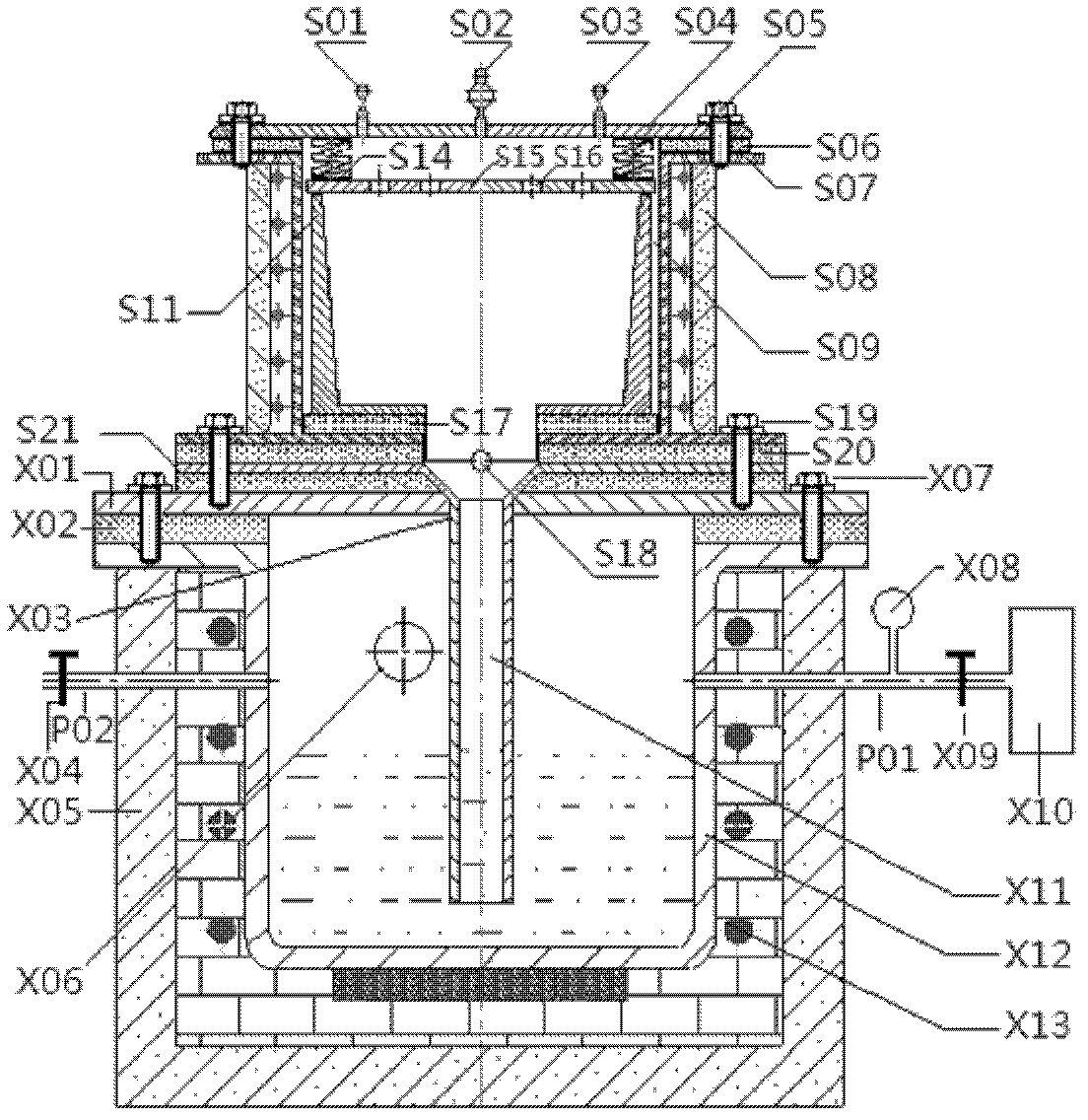

[0035] (2) The mold S11 is hoisted into the casting chamber S09, and a graphite paper gasket S17 is placed between the bottom of the mold and the casting chamber; a breathable part...

Embodiment 2

[0045] The through-hole foamed lead material is prepared by using the device of the present invention.

[0046] The pore-forming material used in this implementation is KCl particles with a particle size of 1.6-2.0 mm, and a Pb-Ag (0.8%) alloy is used as the matrix metal. attached Figure 5 Schematic of the equipment used to prepare the materials for this example. The specific implementation of this embodiment includes the following steps:

[0047] (1) Hang the mold S11 into the casting chamber S09, and place a graphite paper gasket S17 between the bottom of the mold and the casting chamber; place a breathable partition S13 on the bottom of the mold S11; then fill the KCl particles S10 into the mold S11 middle;

[0048] (2) Cover the mold cover plate S15 with air holes S16 on the top of the mold, then place several springs S14 on the mold cover plate S15, and then tightly connect the casting chamber sealing cover plate S04 to the casting chamber cylinder S07 through bolts S...

Embodiment 3

[0055] The device of the invention is used to prepare a sandwich structure arch door frame.

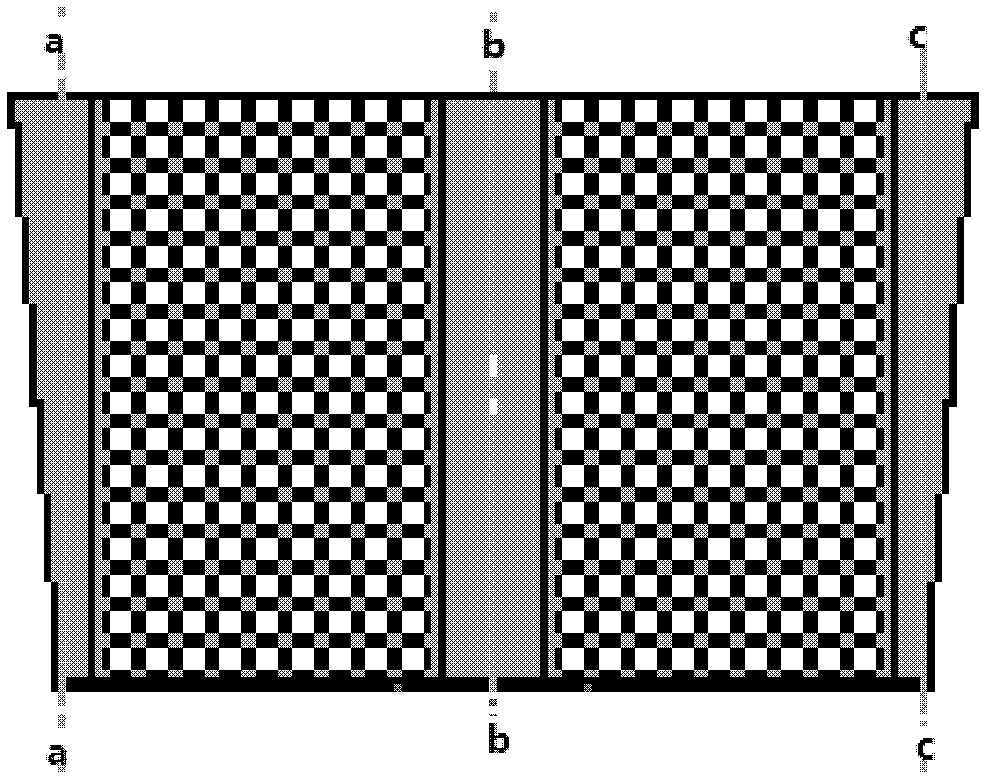

[0056] Sandwich arch door frame described in this embodiment, the surface material is 304 stainless steel with a thickness of 0.5mm, the core material is aluminum / alumina hollow sphere composite material, the particle size of the alumina hollow spheres used is 1.6-2.0mm, and 6063 aluminum is used alloy as aluminum in the core material. Figure 8 Schematic of the equipment used to prepare the materials for this example. The specific implementation of this embodiment includes the following steps:

[0057] (1) Weld a hollow arch door frame with stainless steel plate (see Figure 9 ), the upper part of the door frame has a charging port M01, the bottom of the door frame column is sealed with a bottom plate M03 with holes, and the aperture of the small hole on the bottom plate M03 is 1-1.5mm; the two door frame columns are sealed with refractory material M02. Alumina hollow balls are lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com